A kind of loofah-derived porous silicon carbide ceramic-based high-temperature photothermal storage material and preparation method

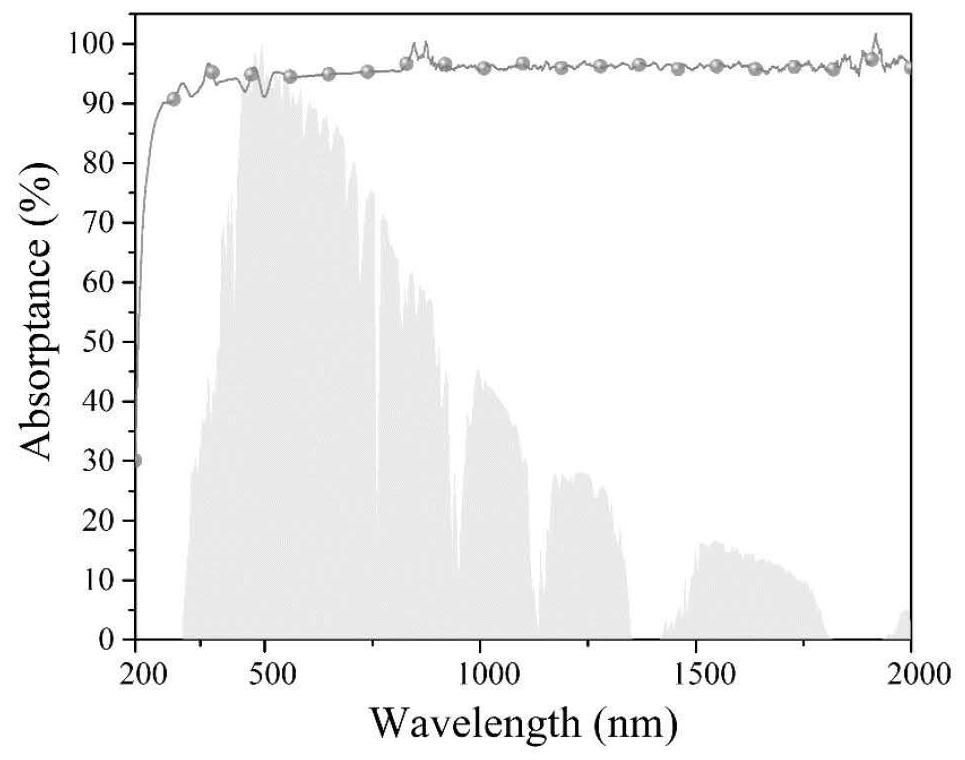

A technology of porous silicon carbide and storage materials, applied in the direction of ceramic products, heat exchange materials, chemical instruments and methods, etc., can solve the problems that the porosity cannot be automatically adjusted and affects the thermal conductivity and heat storage density of heat storage materials, etc., to achieve The effects of excellent connectivity, improved spectral absorption performance, and improved spectral capture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

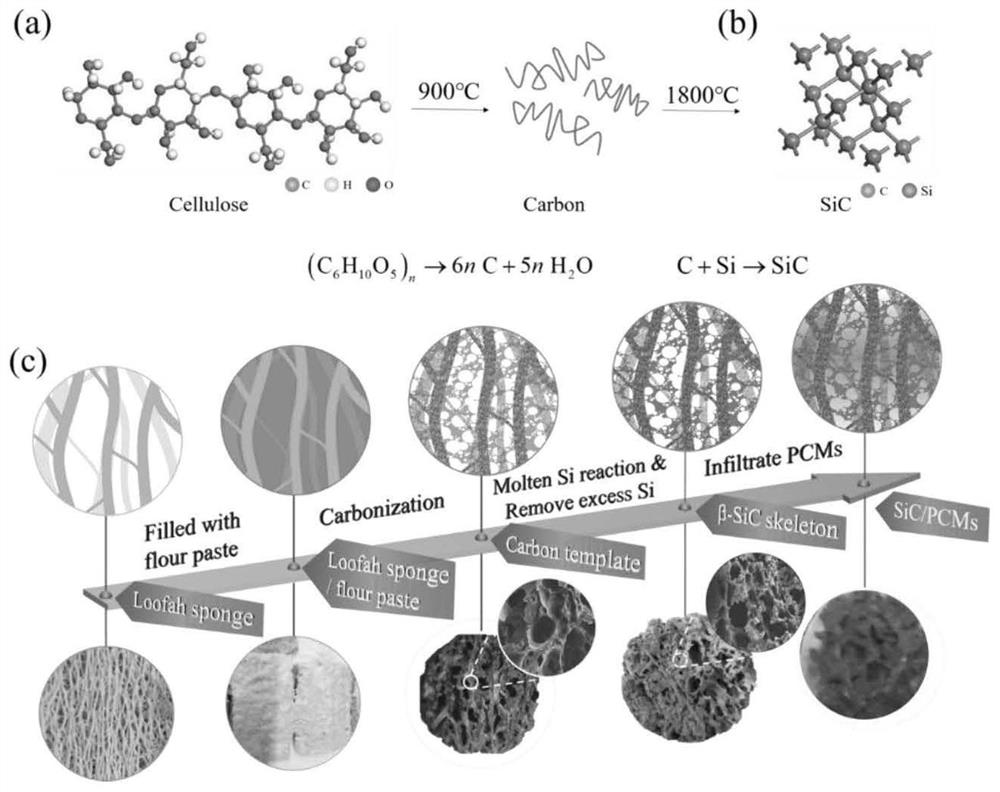

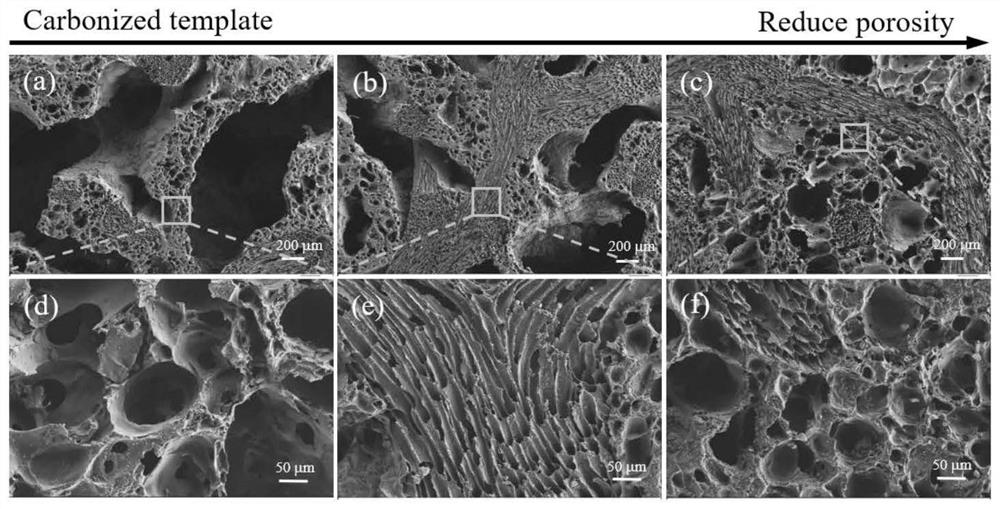

[0033] Step 1: Preparation of loofah-derived porous silicon carbide ceramic framework

[0034] Wash the loofah with ethanol solution and deionized water in turn and place it in a drying oven to dry. Cut the dried loofah, remove the central part of the cylindrical loofah, and keep only the sides of the cylindrical loofah. Dissolve 100 g of low-gluten flour in 90 mL of deionized water and stir mechanically evenly. The low-gluten flour slurry was filled into the pores of the loofah and dried at room temperature for 48 hours. It was then placed in a tube furnace for carbonization, heated to 500°C at a heating rate of 0.5°C / min under an inert gas atmosphere, and then heated to 1000°C at a heating rate of 1°C / min, and kept for 30 minutes. The carbonized porous precursor was cut into a cylindrical sample with a diameter of 13±0.3mm by a circular cutter, and then a disc-shaped sample with a thickness of 3±0.3mm was cut by a diamond wire cutter. The cut porous carbon precursor is pl...

Embodiment 2

[0045] Step 1: Preparation of loofah-derived porous silicon carbide ceramic framework

[0046] Wash the loofah with ethanol solution and deionized water in turn and place it in a drying oven to dry. Cut the dried loofah, remove the central part of the cylindrical loofah, and keep only the sides of the cylindrical loofah. Dissolve 100 g of low-gluten flour in 80 mL of deionized water and stir mechanically evenly. The low-gluten flour slurry was filled into the pores of the loofah and dried at room temperature for 48 hours. It was then carbonized in a tube furnace, heated to 500°C at a heating rate of 0.5°C / min under an inert gas atmosphere, and then heated to 900°C at a heating rate of 1°C / min, and kept for 30 minutes. The carbonized porous precursor was cut into a cylindrical sample with a diameter of 13±0.3mm by a circular cutter, and then a disc-shaped sample with a thickness of 3±0.3mm was cut by a diamond wire cutter. The cut porous carbon precursor was placed in a high...

Embodiment 3

[0052] Step 1: Preparation of loofah-derived porous silicon carbide ceramic framework

[0053] Wash the loofah with ethanol solution and deionized water in turn and place it in a drying oven to dry. Cut the dried loofah, remove the central part of the cylindrical loofah, and keep only the sides of the cylindrical loofah. Dissolve 100 g of cornstarch in 100 mL of deionized water and stir mechanically evenly. The corn starch slurry was filled into the pores of the loofah and dried at room temperature for 48 hours. It was then carbonized in a tube furnace, heated to 500°C at a heating rate of 0.5°C / min under an inert gas atmosphere, and then heated to 1100°C at a heating rate of 1°C / min, and kept for 30 minutes. The carbonized porous precursor was cut into a cylindrical sample with a diameter of 13±0.3mm by a circular cutter, and then a disc-shaped sample with a thickness of 3±0.3mm was cut by a diamond wire cutter. The cut porous carbon precursor was placed in a high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com