Preparation method of halogen-free, low-dielectric-loss and high-heat-resistance copper-clad plate

A low-dielectric, high-heat-resistance technology, used in chemical instruments and methods, electronic equipment, lamination, etc., can solve problems such as restricting applications, and achieve improved mechanical processing properties, improved dielectric properties, and high flame retardant effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

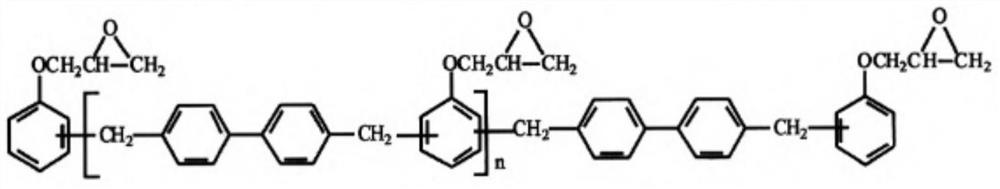

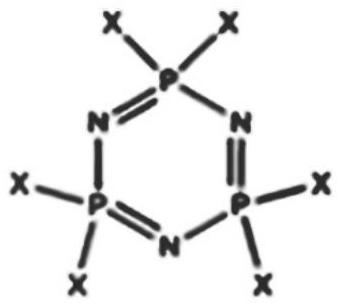

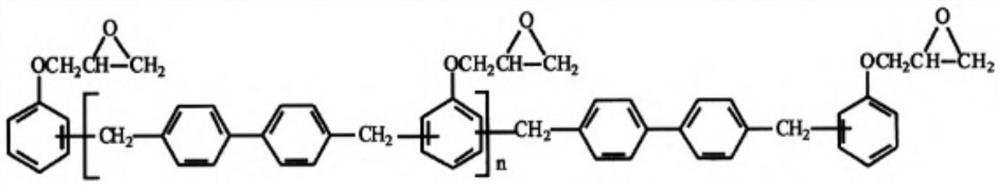

[0029] (1) Preparation of resin glue: In parts by weight, 22 parts of biphenyl type epoxy resin, 85 parts of BT modified PPO resin (Arocy B—10 and 4,4'-diaminodiphenylmethane bisma The B-stage prepolymer of imide is blended with PPO resin at a mass ratio of 1:9), 20 parts of phosphorus-containing flame retardant phosphazene compound (phosphorus content 13%wt), 0.5 parts of curing accelerator 2 - Zinc ethyl octanoate, 0.01 part of 2-methyl 4-ethylimidazole, 0.4 part of dispersant BYK W-903, 100 parts of solvent butanone, 80 parts of filling material high-purity ultrafine spherical nano-amorphous silicon powder, 20 parts of hydrogen Aluminum oxide mixed, emulsified and stirred evenly;

[0030] (2) Dip the low-dielectric electronic grade glass fiber cloth into the resin glue solution prepared in step (1), and pass through a gluing machine at 170° C. to prepare a prepreg.

[0031] (3) Take 6 prepregs prepared in step (2) and stack them together, and cover each side with a piece o...

Embodiment 2

[0037] (1) Preparation of resin glue: in parts by weight, 35 parts of biphenyl type epoxy resin, 75 parts of BT modified PPO resin (Arocy B-10 and 4,4'-diaminodiphenylmethane dimaline The B-stage prepolymer of imide is blended with PPO resin at a mass ratio of 1:9), 10 parts of phosphorus-containing flame retardant resorcinol bis[bis(2,6-dimethylphenyl) Phosphate ester (phosphorus content 10.5%wt), 10 parts of phosphazene compound (phosphorus content 13%wt), 0.5 part of curing accelerator zinc 2-ethyl octanoate, 0.01 part of 2-methyl 4-ethylimidazole, 0.5 100 parts of dispersant BYK W-903, 100 parts of solvent butanone, 100 parts of high-purity ultrafine spherical nano-amorphous silicon micropowder as filler material, emulsified and stirred evenly;

[0038] (2) Dip the low-dielectric electronic grade glass fiber cloth into the resin glue solution prepared in step (1), and pass through a gluing machine at 170° C. to prepare a prepreg.

[0039](3) Take 6 prepregs prepared in st...

Embodiment 3

[0043] (1) Preparation of resin glue: by weight, 60 parts of biphenyl type epoxy resin methyl ethyl ketone solution (50%wt), 140 parts of BT modified PPO resin solution (Arocy B-10 and 4,4' – B-stage prepolymer of diaminodiphenylmethane bismaleimide blended with PPO resin at a mass ratio of 1:9 and dissolved in methyl ethyl ketone, 50%wt), 18 parts of phosphazene compound (Phosphorus content 13%wt), 0.5 parts of curing accelerator zinc 2-ethyloctanoate, 0.01 parts of 2-methyl 4-ethylimidazole, 0.5 parts of dispersant BYK W-903, 10 parts of solvent toluene, 100 parts of filling The material is mixed with high-purity ultrafine spherical nano-amorphous silicon powder, emulsified and stirred evenly;

[0044] (2) Dip the low-dielectric electronic grade glass fiber cloth into the resin glue solution prepared in step (1), and pass through a gluing machine at 180° C. to prepare a prepreg.

[0045] (3) Take 4 prepregs prepared in step (2) and superimpose them together, and cover each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com