Biological enzyme prepared from pigs died of diseases and preparation method thereof

A technology of biological enzymes and dead animals, applied in microbial treatment, combined biological treatment, preparation of organic fertilizers, etc., can solve the problems of easy generation of foul gas and sewage, short time consumption, high cost, and achieve rich varieties, product safety, To achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one: microbial screening in composite bacterial agent

[0047] 1. The selection of microorganisms in the compound microbial agent A.

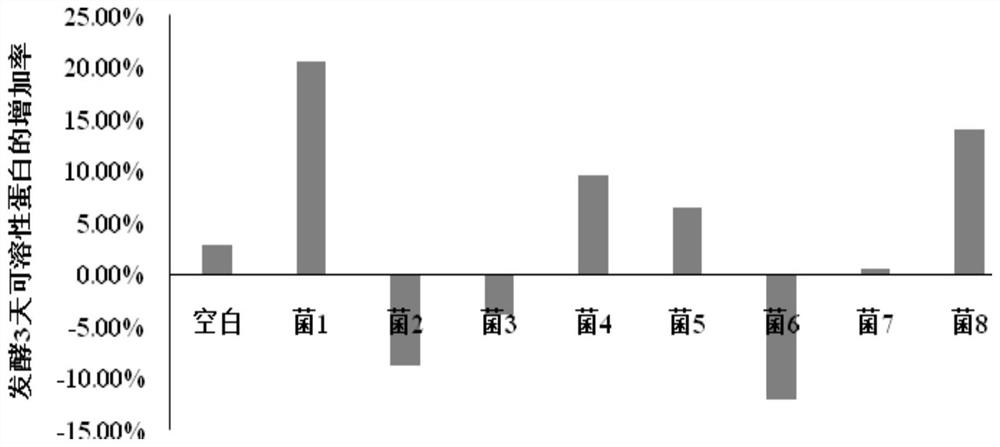

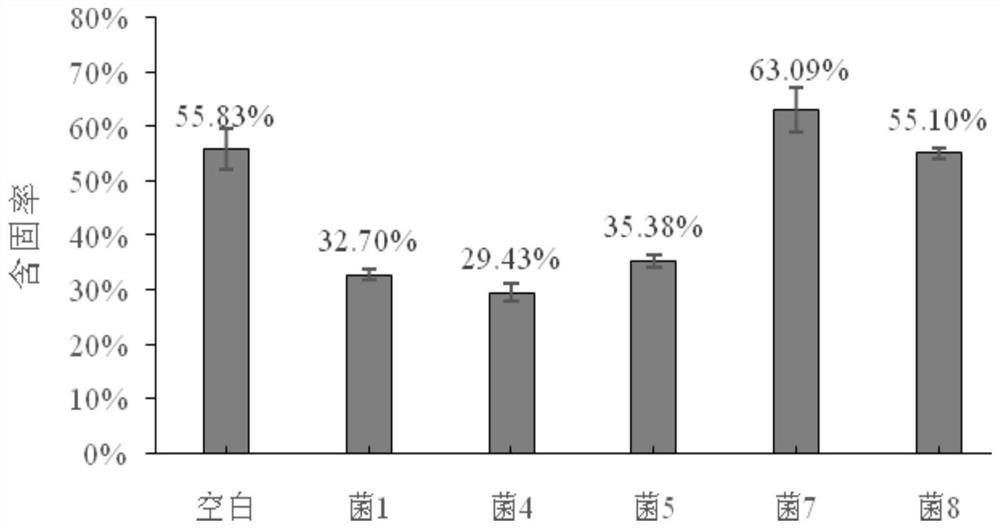

[0048] (1) Screening for protein degradation ability. Set up 8 treatment groups, and in each group, use a meat grinder to crush the lean meat of sick and dead pigs to 50 mesh, add sterilized water according to the mass ratio of pork and water at 1:1, and use high temperature and high pressure to sterilize the crushed materials at 133 °C. Bacteria treatment for 90min. Centrifuge at 10,000 rpm at 4°C, remove the fat solids in the upper part, and make the remaining part into a 200g system, and then sterilize at 121°C for 20min to obtain pork culture medium. Add Bacillus amyloliquefaciens ( figure 1 Bacteria 1), Bacillus thuringiensis ( figure 1 Bacteria 2), Paenibacillus polymyxa ( figure 1 Bacteria 3), Bacillus subtilis ( figure 1 Bacteria 4), Pseudomonas aeruginosa ( figure 1 Bacteria 5), Saccharomyces cerevisiae ( fi...

Embodiment 2

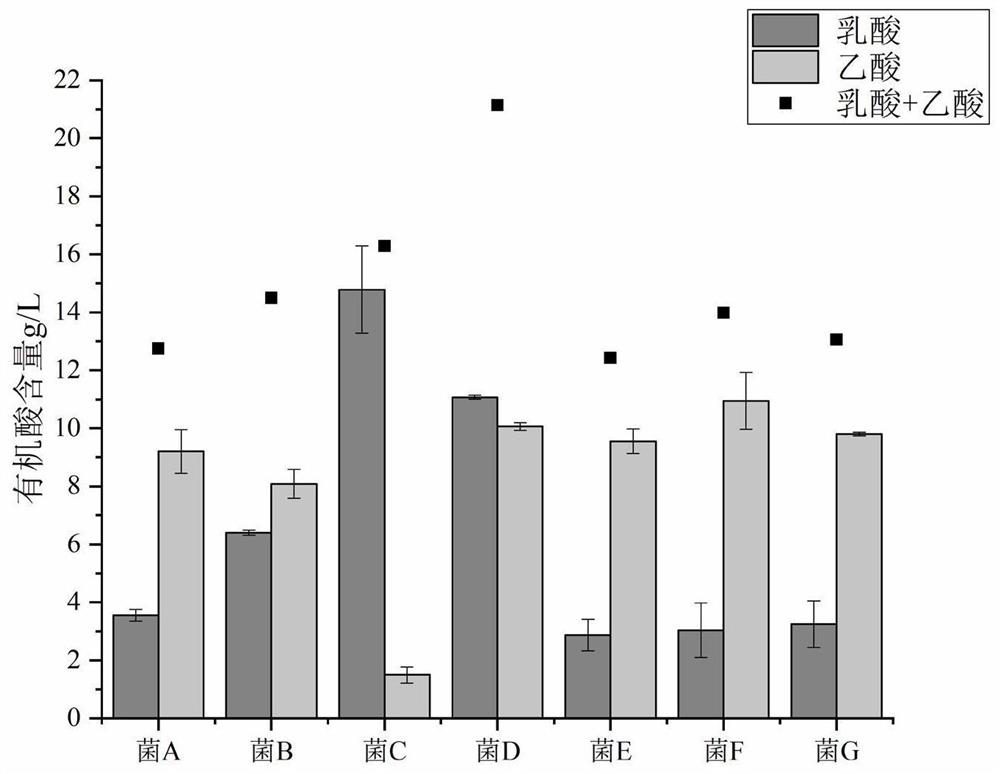

[0062] Example 2: Preparation and effect display of microbial compound bacterial agent

[0063] 1. Prepare compound microbial agent A. Each microorganism in the compound microbial agent A was activated and cultured with beef extract peptone medium until the concentration of viable bacteria was 3×10 8 CFU / mL. Composite microbial agent A is configured in the manner shown in Table 3. Each numerical value in Table 2 is the volume ratio (i.e. live bacteria ratio) of each microorganism bacterium liquid; For example, group 4 refers to by bacterium liquid volume ratio (or by live bacteria ratio), Pseudomonas aeruginosa: Bacillus amyloliquefaciens: subtilis Bacillus = 1:2:2. Among them, the commercially purchased Pseudomonas aeruginosa comes from Shanghai Fuxiang Biotechnology Co., Ltd. (ATCC15442); the commercially purchased Bacillus amyloliquefaciens comes from Weifang Ruichen Biotechnology Co., Ltd.; the commercially purchased Bacillus subtilis comes from Shanghai Fuxiang Biotech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com