Ternary precursor and preparation method and application thereof

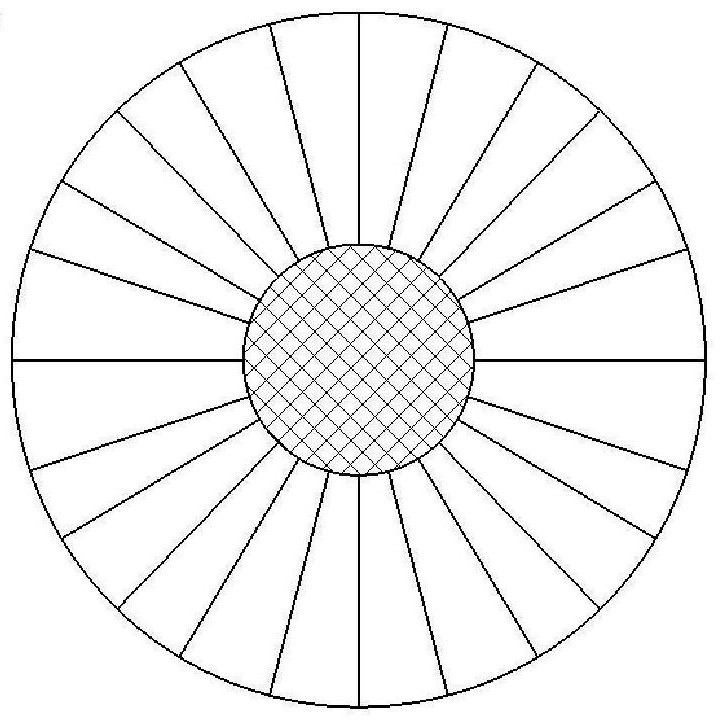

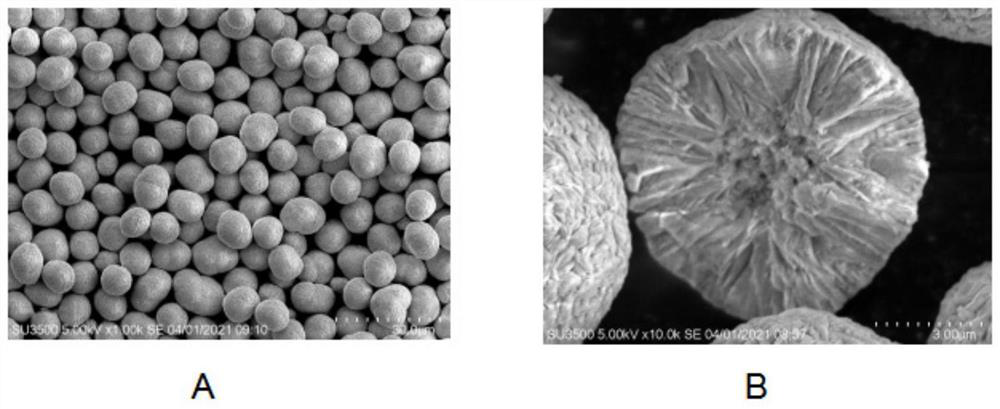

A precursor and reaction technology, applied in the field of ternary precursors and their preparation, can solve the problems of poor circulation, spheroids prone to microcracks, low capacity, etc., and achieves the effects of small DCR, uniform primary particle distribution and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the embodiment of the present application provides a method for preparing a ternary precursor, including the following steps:

[0037] S01. Provide the first mixed solution of nickel ions, cobalt ions, manganese ions, soluble salt mixed solution, precipitant, complexing agent and bottom liquid, pass inert gas to create micro-nano bubble aqueous solution conditions, carry out the first mixed reaction to obtain the first For the precipitate, when the median particle size of the first precipitate reaches the first target particle size, the feeding is stopped and aging treatment is performed to obtain the ternary precursor crystal nucleus;

[0038] S02. The ternary precursor crystal nucleus, nickel ion, cobalt ion, manganese ion soluble salt mixed solution, precipitant and complexing agent are subjected to the second mixed reaction to obtain the second precipitate, when the median particle size of the second precipitate When the diameter reaches the sec...

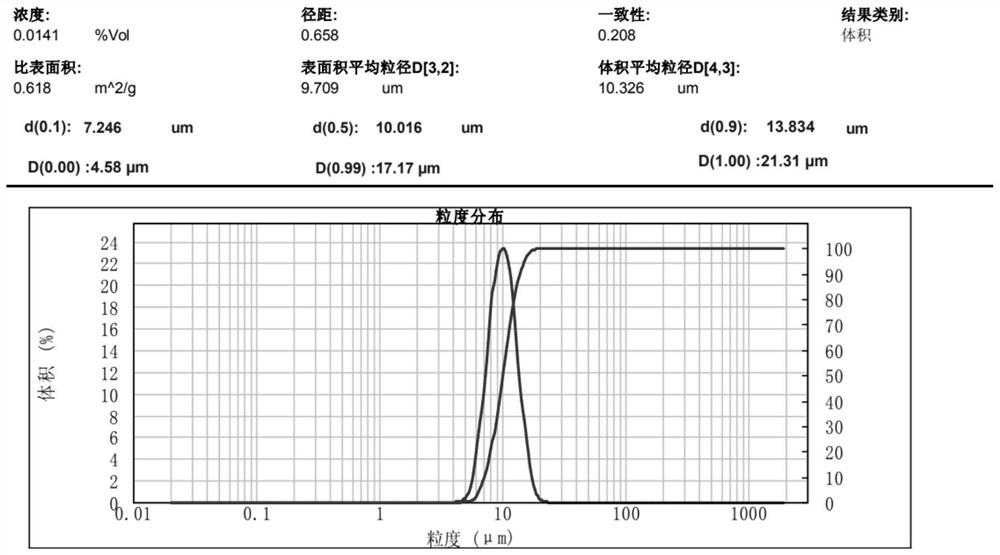

Embodiment 1

[0075] A preparation method of a ternary cathode material precursor, comprising the following steps:

[0076] (1) The total molar weight of nickel, cobalt and manganese is 1.5mol / L, the molar ratio of nickel, cobalt and manganese is 80:10:10, mixed solution of sulfate, 32wt% NaOH solution, 13.5wt% ammonia Three kinds of materials, such as aqueous solution, are fed at a uniform speed by a metering pump at the same time, and are respectively transported to the reaction kettle containing the bottom liquid. The temperature of the reaction system is controlled at 50°C, protected by a nitrogen atmosphere, and the nitrogen flow rate of the micro-nano bubble machine is 0.3L / h. The reaction process The pH is 11.0-11.50, the ammonium root concentration is 1.0-2.0g / L, the stirring speed is 200rpm, and the material in the reactor reaches 80% of the effective volume of the reactor to stop feeding. Among them, the bottom solution has an ammonium root concentration of 2.0-3.0g / L, a pH of 10....

Embodiment 2

[0081] A preparation method of a ternary cathode material precursor, comprising the following steps:

[0082] (1) The total molar weight of nickel, cobalt and manganese is 2.0mol / L, the molar ratio of nickel, cobalt and manganese is 90:0.5:0.5 sulfate mixed solution, 32wt% NaOH solution, 13.5wt% ammonia solution The three materials are fed at a uniform speed by the metering pump at the same time, and are respectively transported to the reaction kettle containing the bottom liquid. The temperature of the reaction system is controlled at 60°C, protected by a nitrogen atmosphere, and the nitrogen flow rate of the micro-nano bubble machine is 0.5L / h. The pH of the reaction process At 11.0-11.50, the ammonium root concentration is 1.5-2.5g / L, the stirring speed is 200rpm, and the material in the reactor reaches 80% of the effective volume of the reactor to stop feeding. Among them, the bottom liquid has an ammonium root concentration of 3.0-4.0g / L, a pH of 10.90-11.20, and a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com