Environment-friendly device and structure for absorbing external heat to evaporate water and concentrating deuterium water and tritium water

A technology for evaporating water and the outside world, which is applied in the separation of different isotopic elements, the separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of complex process, impact on the ecological environment of the Pacific Ocean, and high production cost, and achieve simple equipment structure and ease the global Effect of warming and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

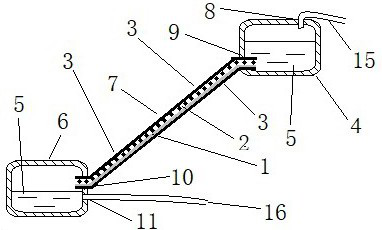

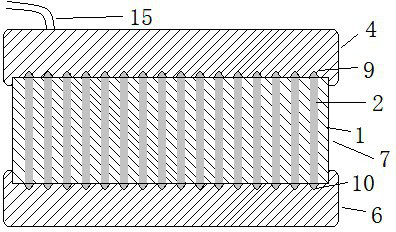

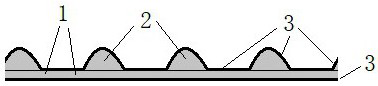

[0070] This embodiment provides a broadband evaporative separator, such as Figure 1-4 As shown, it includes water absorbent 1, water guide strip 2, separation membrane 3, water storage 4, water 5, water collector 6, device main body 7, water injection port 8, water outlet 9, water inlet 10, drain port 11, Water injection pipe 15, drainage pipe 16, cavity 19, micropore 20; Described absorbent material 1 is the natural fiber of length 1m-10m, width 1m-10m, thickness 0.1mm-1mm and / or chemical fiber and its fabric (such as Absorbent cotton cloth, absorbent cotton yarn, absorbent paper towel, quick-drying imitation cotton cloth, absorbent non-woven fabric, etc., as long as they can be wetted by the water 5 and have a capillary structure on the surface and / or inside); the water guide strip 2 can be any Cylindrical water-absorbing objects with a length of 5mm-50mm in diameter (such as absorbent cotton slivers, water-absorbing chemical fiber strips, etc., as long as they can be wette...

no. 2 example

[0073] This embodiment provides a sandwich type evaporative separator, such as figure 1 , 2 As shown in , 4 and 5, the package includes absorbent 1, water guide strip 2, separation membrane 3, water storage 4, water 5, water collector 6, device main body 7, water injection port 8, water outlet 9, water inlet 10 , drain outlet 11, water injection pipe 15, drain pipe 16, cavity 19, micropore 20; The specific composition, structure, working principle of this embodiment are basically the same as the first embodiment, and the difference with the first embodiment is that : the water guide strip 2 is located in the interlayer of the water absorbent 1, so that the water 5 can also be evaporated and liquefied in the interlayer of the water absorbent 1, and the water vapor formed by the evaporation of the water 5 can Deuterium water and tritium water are easier to liquefy and remain in the raffinate.

no. 3 example

[0075] This embodiment provides a reflux evaporative separator, such as Figure 4 , 6 , 7 and 8, water absorber 1, water guide strip 2, separation membrane 3, water storage 4, water 5, water collector 6, device main body 7, water injection port 8, water outlet 9, water inlet 10, drainage Port 11, water injection pipe 15, drain pipe 16, return pump 17, cavity 19, micropore 20; the specific composition, structure and working principle of this embodiment are basically the same as those of the first embodiment, and the differences with the first embodiment The advantages are: firstly, the water guiding strip 2 is not provided; secondly, the horizontal width of the absorbent 1 (that is, the width of the same horizontal plane) is ≤100mm, so that the water 5 in the water storage 4 can be Under the gravitational self-flow of water (that is, the flow of water from top to bottom) and the capillary action of the absorbent 1, the effect of wetting all the absorbent 1, if this effect cann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com