Metal oxide-graphene quantum dot composite material, preparation method and application thereof

A technology of graphene quantum dots and composite materials, applied in the field of metal oxide-graphene quantum dot composite materials and their preparation, can solve the problem that the electrical conductivity cannot be fundamentally improved, the charge-discharge reaction mechanism is complex, and the optimization results are not ideal, etc. problem, to achieve the effect of improving low electronic conductivity, improving cycle stability, and improving transport kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 1. Preparation of graphene quantum dots

[0039] Graphene quantum dots (GQDs) are obtained by chemical oxidation method, the specific preparation method is as follows:

[0040] First, add 1 g of 325-mesh graphite flakes into concentrated H 2 SO 4 / HNO 3 (60mL, V / V, 3:1), then magnetically stirred for 10 minutes to obtain a dispersion; the dispersion was sonicated for one hour; after that, the resulting mixture was transferred to a 100mL stainless steel autoclave lined with polytetrafluoroethylene , and then put the sealed autoclave into an oven, heat it to 120°C and keep it warm for 24 hours; 2 CO 3 Neutralize with NaOH to pH = 7; then suction filter to remove large particles of graphite and dialyze to remove small molecular salts, and finally freeze-dry to obtain the final CQDs powder with a diameter of 2-4 nm.

[0041] The graphene quantum dots used in the following examples are all graphene quantum dots prepared by the above method.

Embodiment 1

[0043] MnO 2 -The preparation of 10GQDs composite material, comprises the following steps:

[0044] S1. Dissolve 10mg of GQDs in 60mL of deionized water, and stir magnetically to form a uniform GQDs dispersion;

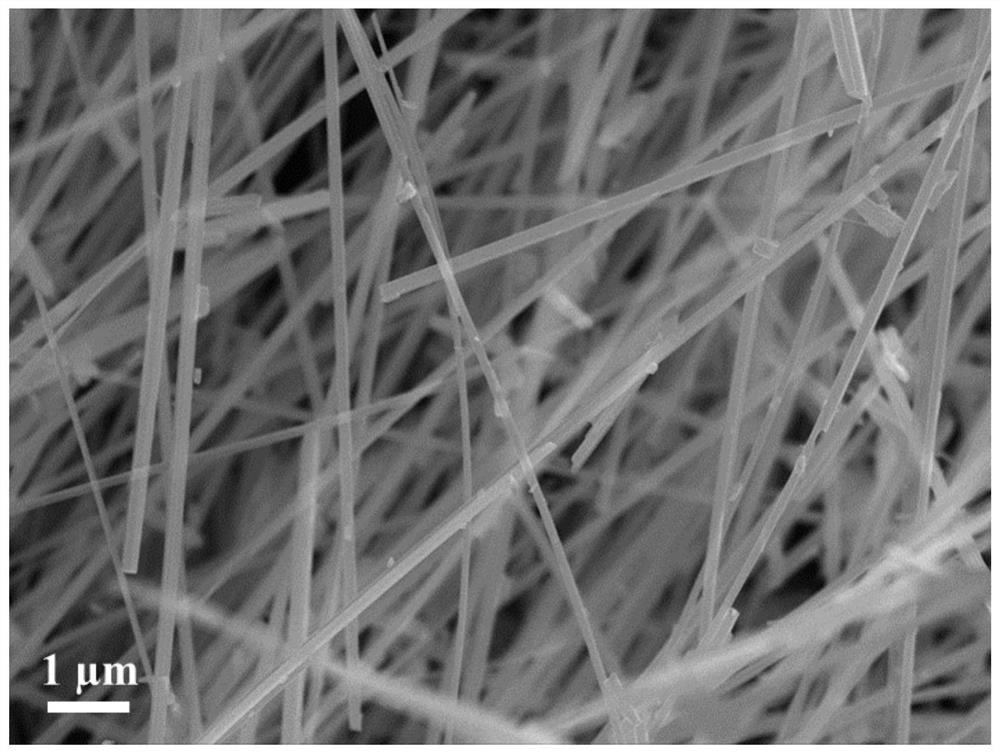

[0045] S2, with 7mmol potassium chlorate (KClO 3 ), 4mmol manganese(II) sulfate monohydrate (MnSO 4 ·H 2 O) and 7 mmol potassium acetate (CH 3 COOK) was added to the above GQDs dispersion, and magnetically stirred until dissolved to obtain a mixed solution; then 3.2mL acetic acid (CH 3 COOH) was added dropwise to the above mixed solution and stirred for 30 minutes to obtain a uniform mixed solution, which was transferred to a 100mL stainless steel autoclave lined with polytetrafluoroethylene, heated to 160°C and kept for 12 hours; After completion, cool down to room temperature, filter to obtain the precipitate, wash with distilled water and ethanol several times, and dry at 55°C for 24 hours to obtain MnO 2 - 10GQDs composites. After detection, MnO 2 The morp...

Embodiment 2

[0049] MnO 2 -The preparation of 20GQDs composite material comprises the following steps:

[0050] S1. Dissolve 20mg of GQDs in 60mL of deionized water, and stir magnetically to form a uniform GQDs dispersion;

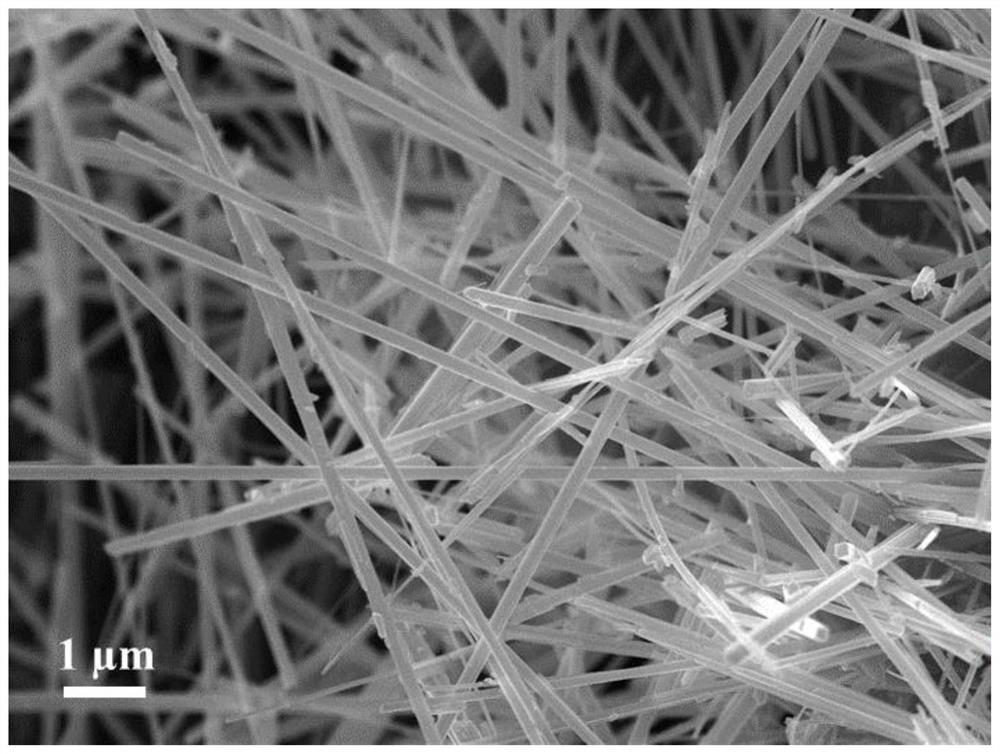

[0051] S2, with 7mmol potassium chlorate (KClO 3 ), 4mmol manganese(II) sulfate monohydrate (MnSO 4 ·H 2 O) and 7 mmol potassium acetate (CH 3 COOK) was added to the above GQDs dispersion, and magnetically stirred until dissolved to obtain a mixed solution; then 3.2mL acetic acid (CH 3 COOH) was added dropwise to the above mixed solution and stirred for 30 minutes to obtain a uniform mixed solution; the uniform mixed solution was transferred to a 100mL stainless steel autoclave lined with polytetrafluoroethylene, heated to 160°C and kept for 12h; After completion, cool down to room temperature, filter the precipitate, wash with distilled water and ethanol several times, and dry at 55°C for 24 hours to obtain MnO 2 - 20GQDs composite material. After detection, Mn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com