Preparation method of antibacterial plastic film

A plastic film and bacteria-resistant technology, which is applied in the field of plastic film production, can solve the problems of human harm, fast release of antibacterial substances, and low service life, and achieve the effects of improved oil resistance, simple raw materials, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

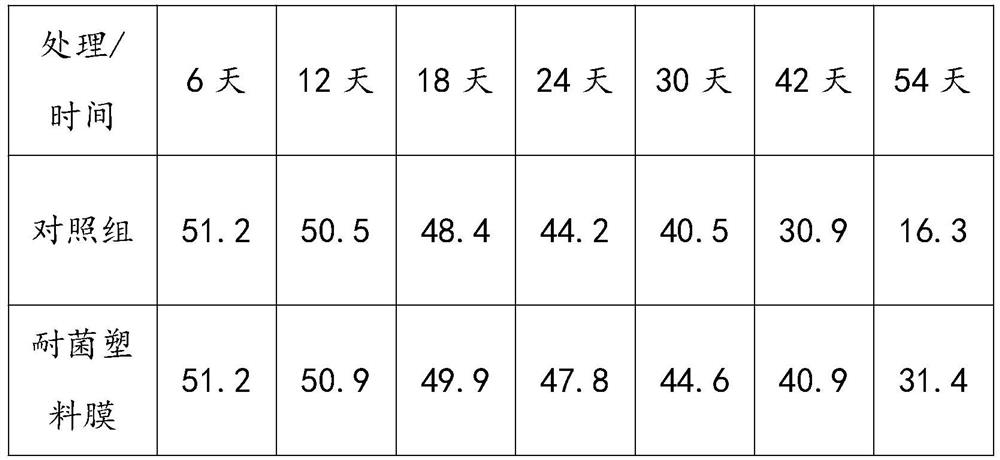

Image

Examples

Embodiment 1

[0029] The embodiment of the present invention provides a kind of preparation method of antibacterial plastic film, comprises the following steps:

[0030] S1. Take a certain amount of polypropylene pellets, fuse them with a certain amount of solvent, and prepare the polypropylene film base layer by casting process; adopt microporous polypropylene film as the base layer, the physical stability of this film, Good mechanical strength and air tightness, high transparency and gloss, tough and wear-resistant;

[0031] S2. After fully mixing a certain amount of polyethylene resin and ultra-fine Zanthoxylum bungeanum powder, melt it through an extruder, extrude it into a film, cool it down and shape it, and then stretch it to obtain a microporous film; Zanthoxylum bungeanum has antibacterial and insect-repelling properties. Efficacy, use ultra-fine pepper powder to fill and fuse polyethylene resin to form a micro-breathable air-porous film, so that the micro-porous film has good air ...

Embodiment 2

[0041] The difference between this embodiment and the above-mentioned embodiments is that the pretreatment of the polypropylene film base layer also includes the following methods: soak the polypropylene film base layer in the adhesive, take it out after soaking for a period of time, and dry the polypropylene film base layer; Soak the base layer of the polypropylene film in the antibacterial adhesive, take it out after soaking for a period of time, and dry the base layer of the polypropylene film to obtain the base layer of the polypropylene film with the surface of the antibacterial adhesive, which can make the adhesive fully absorb the antibacterial Bacteria adhesive adheres to the surface of the polypropylene film base layer to maintain the antibacterial properties and prolong the service life.

Embodiment 3

[0043] On the basis of the above embodiments, this embodiment provides an adhesive, the adhesive is a silicone adhesive, the preparation method of the silicone adhesive includes the following steps: weighing 65% of the silicone adhesive by mass percentage, 32% of hydroxy polysiloxane and 3% of silane coupling agent are fully mixed to obtain a silicone adhesive, and the organic silicon adhesive with exhaust and adsorption properties is prepared to facilitate the formation of exhaust channels, which is beneficial to Chinese herbal medicines. Bactericides are small molecules that exert a bactericidal effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com