Method for stably preparing pseudo-boehmite under mild condition

A pseudo-boehmite and conditional technology, which is applied in the field of chemical alumina preparation, can solve the problems of unstable pseudo-boehmite, high production cost, toxicity of precipitant formamide, etc., and achieve non-toxic and harmless raw materials , short reaction time and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

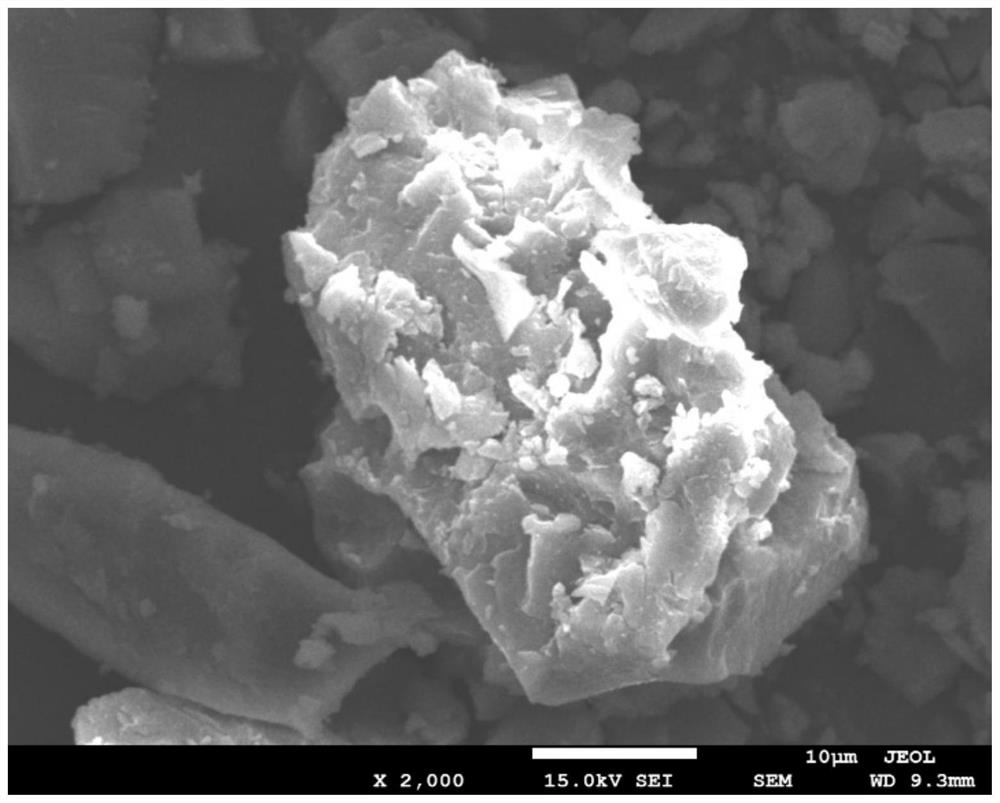

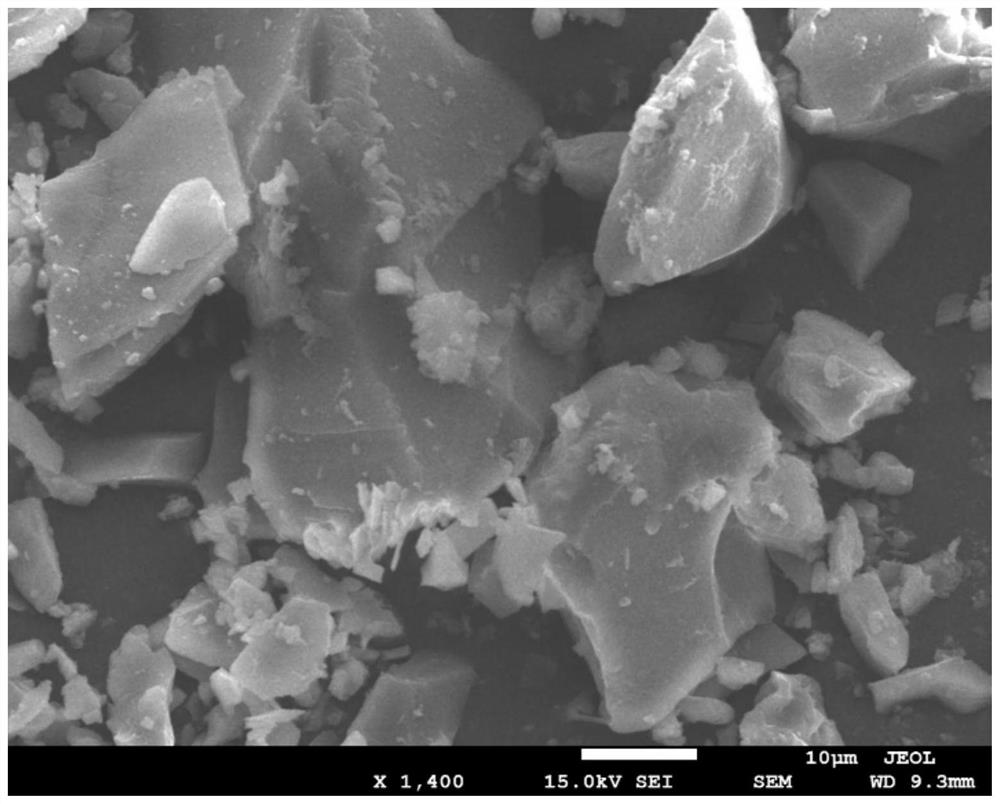

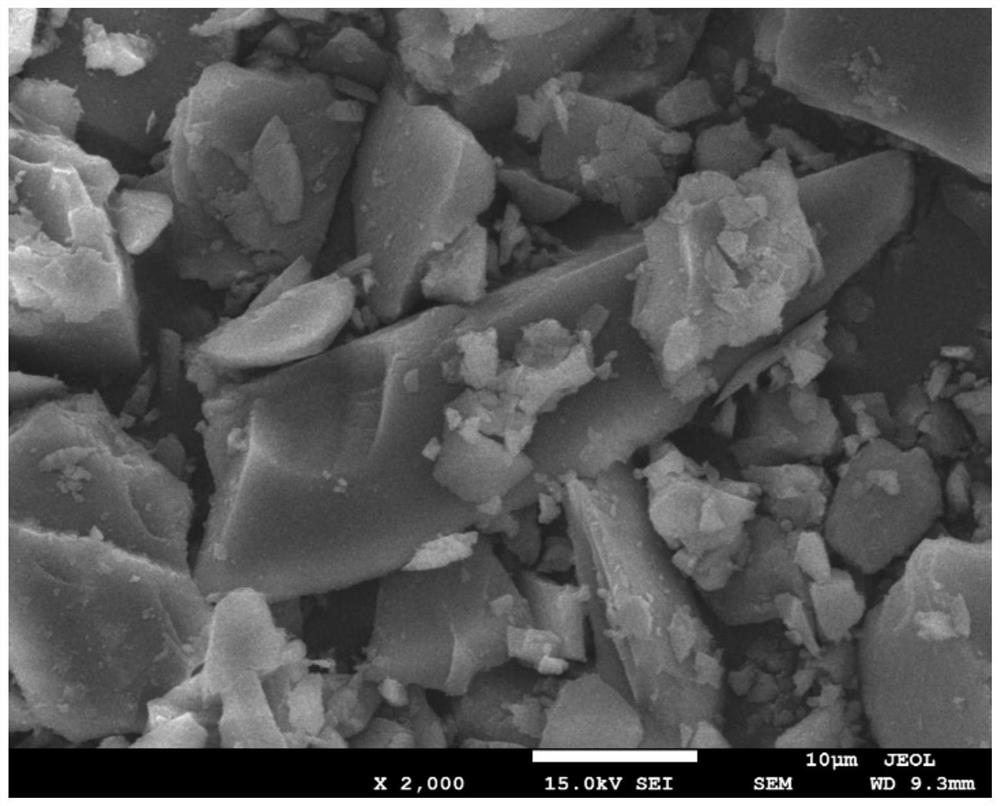

Image

Examples

Embodiment 1

[0035] (1) Weigh 0.83g of sodium aluminate and dissolve it in 25mL of deionized water, stir and dissolve at room temperature to obtain a sodium aluminate solution, measure 25mL of ethylene glycol and add it to the sodium aluminate solution and continue magnetic stirring for 1min to form a clear mixture liquid;

[0036] (2) Put the mixed solution obtained in step (1) in a reaction kettle for hydrothermal reaction at 60°C for 2 hours, centrifuge the reaction product and wash it with deionized water for 3 times to obtain a filter cake, which is blown at 60°C Dry in a dryer for 12 hours to obtain pseudo-boehmite.

Embodiment 2

[0038] (1) Weigh 1.0g of sodium aluminate and dissolve it in 25mL of deionized water, stir and dissolve at room temperature to obtain a sodium aluminate solution, measure 25mL of ethylene glycol and add it to the sodium aluminate solution and continue magnetic stirring for 1min to form a clear mixture liquid;

[0039] (2) Put the mixed solution obtained in step (1) in a reaction kettle for hydrothermal reaction at 60°C for 2 hours, centrifuge the reaction product and wash it with deionized water for 3 times to obtain a filter cake, which is blown at 60°C Dry in a dryer for 12 hours to obtain pseudo-boehmite.

Embodiment 3

[0041] (1) Weigh 1.2g of sodium aluminate and dissolve it in 25mL of deionized water, stir and dissolve at room temperature to obtain a sodium aluminate solution, measure 25mL of ethylene glycol and add it to the sodium aluminate solution and continue magnetic stirring for 1min to form a clear mixture liquid;

[0042] (2) Put the mixed solution obtained in step (1) in a reaction kettle for hydrothermal reaction at 60°C for 2 hours, centrifuge the reaction product and wash it with deionized water for 3 times to obtain a filter cake, which is blown at 60°C Dry in a dryer for 12 hours to obtain pseudo-boehmite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com