Semiconductor composite photo-anode, production method and application

A compound light and semiconductor technology, applied in the field of photoelectrochemistry, can solve the problems of high carrier recombination rate and limited photoresponse range of semiconductor materials, so as to improve utilization efficiency, improve photogenerated cathodic protection effect, and improve electron hole transport capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of semiconductor composite photoanode and its performance testing

[0034] 1. Preparation method

[0035] (1) FTO (conductive glass) pretreatment

[0036] Cut the FTO into small pieces with a size of about 1.5×1cm, then put the FTO into a beaker, and ultrasonically clean it with acetone, ethanol, and distilled water for about 15 minutes for later use.

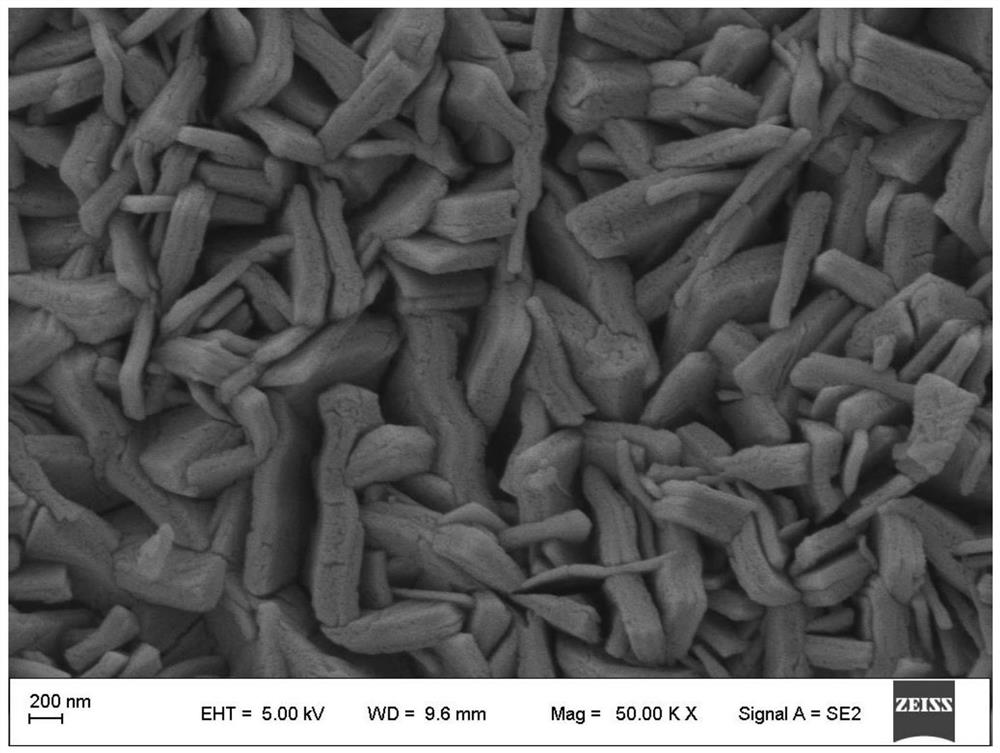

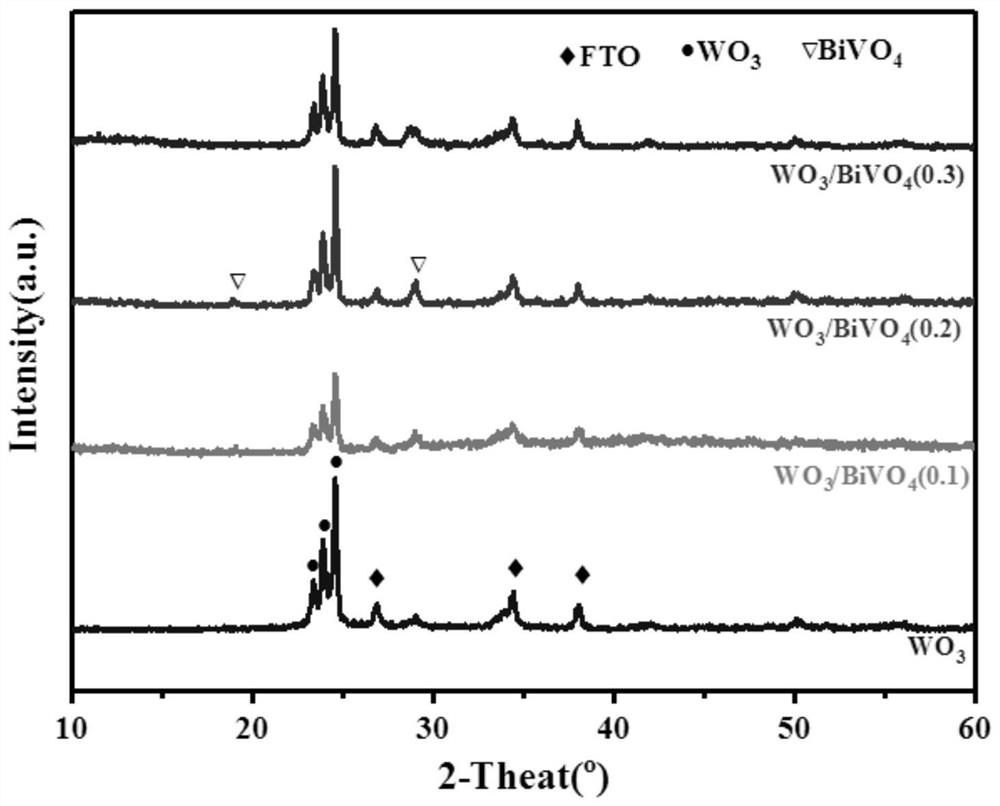

[0037] (2) WO 3 Preparation of the seed layer

[0038] 0.625 g of tungstic acid and 0.25 g of polyethylene glycol-8000 were dissolved in 10 mL of 30 wt % hydrogen peroxide to obtain a yellow solution. Use a pipette gun to drop-coat the solution onto the pretreated FTO, and put it on a homogenizer for spin-coating at a speed of 3000 rpm for 30 s. After the spin coating, the glass sheet was quickly heated in an oven at 100 °C for 10 min, and finally annealed at 500 °C for 2 h in a tube furnace with a heating rate of 3 °C / min, finally forming WO 3 seed layer.

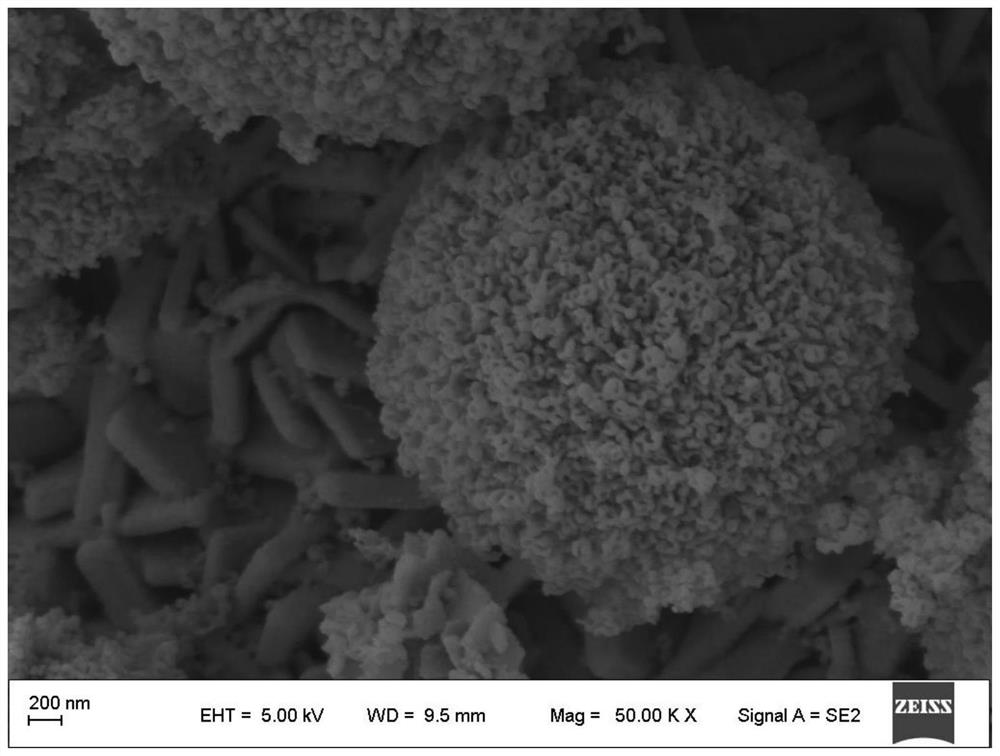

[0039] (3) Preparation of WO-coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com