Cross-scale simulation method for predicting gelation process of water-based alumina precursor

A sol-gel, simulation method technology, applied in chemical process analysis/design, cheminformatics programming language, computational theoretical chemistry, etc., can solve problems such as inability to characterize microscopic structures and complex molecular structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The invention provides a cross-scale simulation method for predicting the gelation process of a water-based alumina precursor sol, which specifically includes the following steps:

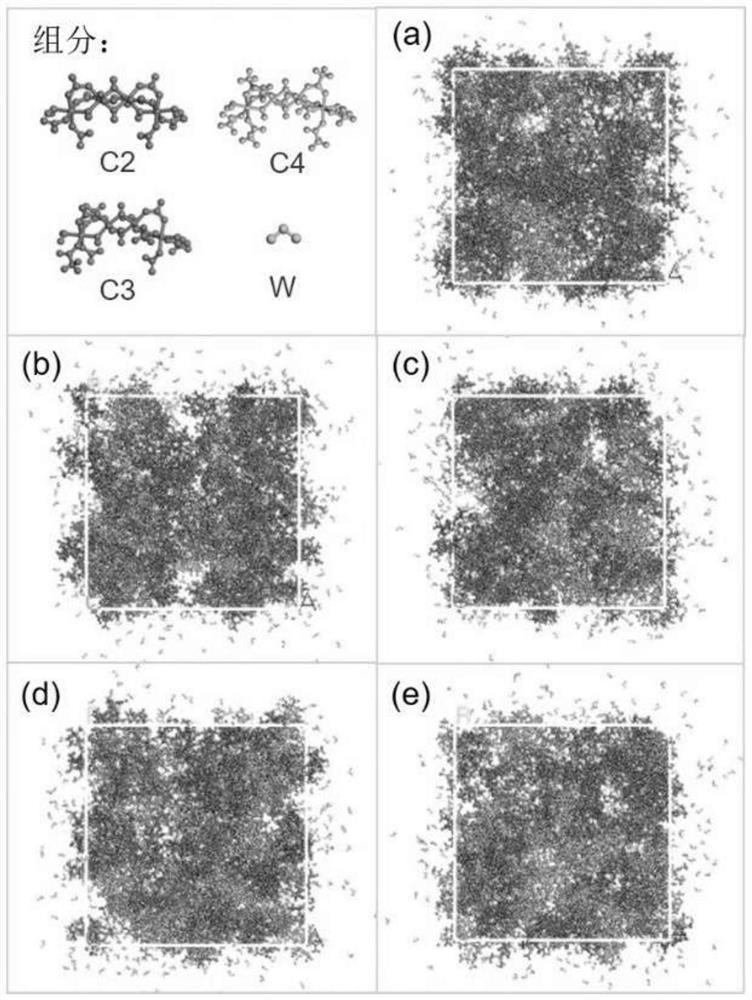

[0067] (1) At present, using aluminum powder, formic acid, acetic acid and deionized water as the raw material system, our research group uses the density functional theory (DFT) combined with the conductor polarization continuum model (CPCM), using the B3LYP method and 6-311G** The basis group obtained the oligomer structure of the related aluminum carboxylate system sol (patent application number: CN202011173292.0). Import the structure file into MaterialsStudio to get the structure formula as figure 1 -C2, figure 1 -C3, 1-C4 and figure 1 -W shows, respectively, hydroxyaluminum diformate tetramer, hydroxyaluminum formate acetate tetramer, hydroxyaluminum diacetate tetramer and water molecules;

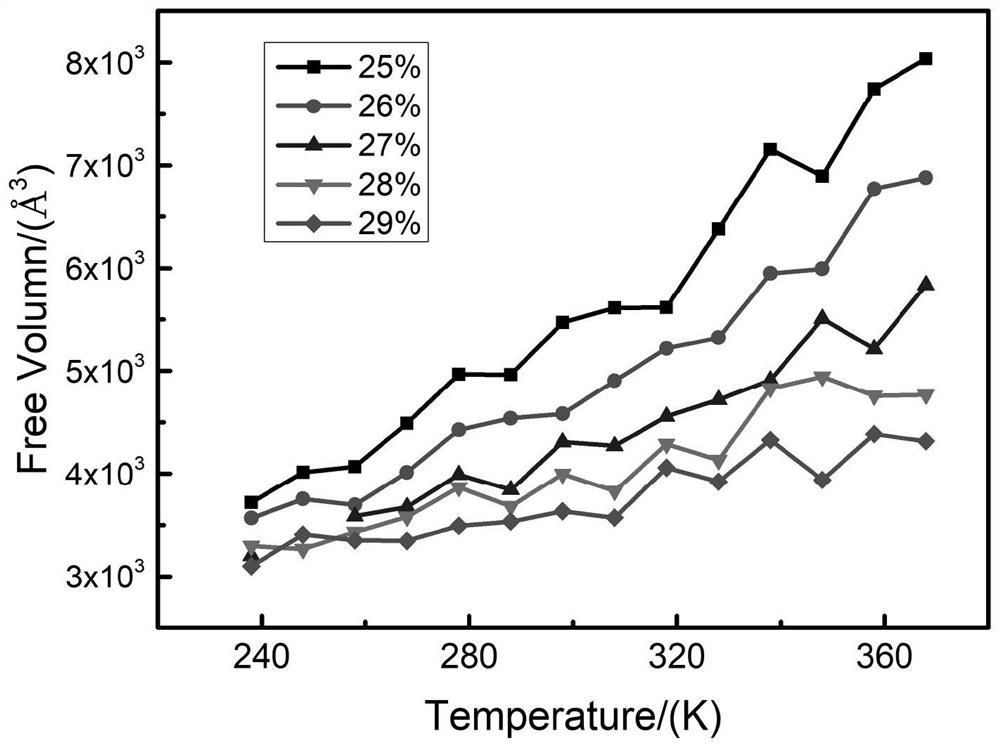

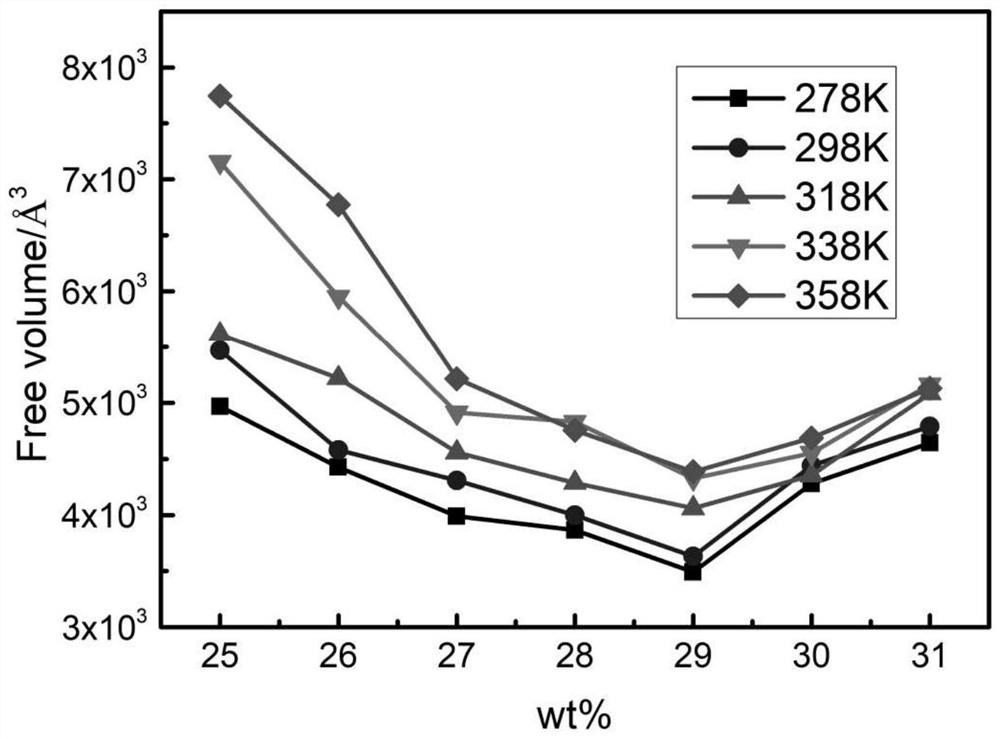

[0068] (2) Use the Materials Studio software for modeling, use the Amorphous Cell module, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com