Preparation method of alkyl phosphonic acid diaryl ester

A technology of diaryl alkyl phosphonate and dialkyl alkyl phosphonate, which is applied in the field of preparation of diaryl alkyl phosphonate, can solve problems such as difficult industrial preparation and influence on product color, and achieve The effect of complete reaction, strong catalytic activity, and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

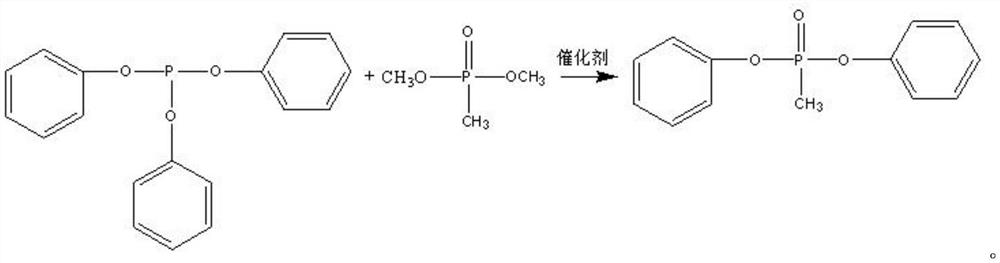

[0022] The present invention provides a method of preparing an alkylphosphonic acid diaryl ester, comprising the steps of:

[0023] In the protective atmosphere, the phosphite triaryl ester is mixed with the alkylphosphonic acid dialkyl ester to obtain an isomerization reaction product system by mixing the phosphite.

[0024] The isomerization reaction product system was first reduced pressure distillation, and the residual system was mixed with an inert orprotic solvent, and the resulting liquid material was sequentially washed, water washing and second pressure reduction distillation to obtain an alkane Narphonic acid diaryl ester.

[0025] In the protective atmosphere, the phosphite triaryl ester is mixed with the alkylphosphonic acid dialkyl ester in the protective atmosphere to obtain an isomerization reaction product system. The present invention is not particularly limited to providing the protective gas of the protective atmosphere, and is specifically, such as nitrogen. I...

Embodiment 1

[0040] Diphenyl methylphosphonic acid, including the steps of:

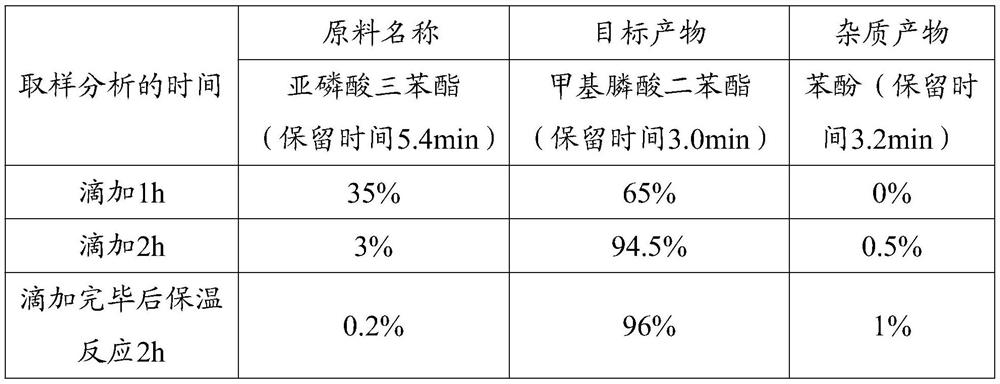

[0041] (1) Tutinyl phosphite (620 kg, 2 kmol) and the catalyst absorbed until the nickel (1.29% of the mass of triphenyl ester of phosphite) were added to the reactor, and the nitrogen protection was raised to 180 ~ 200 ° C, then Methyl phosphomethane (273 kg, 2.2 kmol) of methylphosphonic acid (273 kg, 2.2 kmol) was slowly added dropwise, and the dropwise addition was 2 h. After the dropwise addition was completed, the liquid chromatographic monitor reaction progression, the phosphite triphenyl reaction was completely The reaction was stopped to obtain a product system; data using liquid chromatography during the reaction as shown in Table 1, the content of each substance in Table 1 is a mass content:

[0042] Table 1 Monitoring data using liquid chromatography

[0043]

[0044] (2) The product system is lowered to 70 to 80 ° C, and the first decompression distillation is carried out under a vacuum degree of 3 to ...

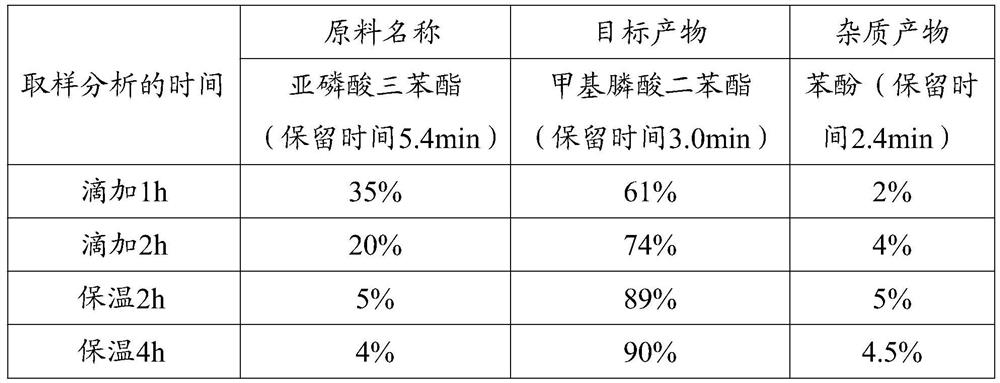

Embodiment 2

[0051] As in Example 1, the difference is only that the reaction temperature is 200 to 210 ° C; the final prepared target product was 95%, the phenol content was 180 ppm, the acid value was 0.16 mg KOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com