Catalyst for purifying CO in hydrogen-rich gas as well as preparation method and application of catalyst

A technology for purifying catalysts and enriching hydrogen, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of insufficient CO purification depth and water resistance, Achieve the effect of simple and rapid modification process, increase upload capacity, and increase CO removal depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing a CO purification catalyst in hydrogen-rich gas, comprising the following steps:

[0043] (1) Carry out pretreatment to the boring base material;

[0044] (2) prepare copper salt precursor, cerium salt precursor, metal M salt precursor and sepiolite powder to be mixed into slurry, the preparation volume total amount of described slurry is the saturation of the slurry by the pretreated pore-opening substrate The total amount of adsorption;

[0045] (3) using the slurry to infiltrate the pretreated hole-boring substrate to obtain a hole-boring substrate soaked with the slurry;

[0046] (4) Drying the hole-expanding substrate soaked with the slurry, and then roasting to obtain a catalyst for purifying CO in hydrogen-rich gas.

[0047] In some possible embodiments of the present invention, the hole-expanding substrate is selected from one of natural cotton or loofah whose main components are C, H, and O, and the volume porosity ...

Embodiment 1

[0057] Select natural cotton with a volume porosity of 65% as the hole-expanding substrate, cut the hole-expanding substrate with a weight of 1 g, wash it once with deionized water, then wash it twice with absolute ethanol, and then move it to a vacuum drying oven at 100°C Dry 8h. Take out the boring base material, place it in a coaxial tubular dielectric barrier reactor, and carry out discharge modification under the protection of 150mL / min argon (Ar), and pause for 2 minutes every 2 minutes of discharge modification, and control the discharge power at 15KW. The total time is 8 minutes.

[0058] Weigh 0.906g copper nitrate trihydrate, 13.026g cerium nitrate hexahydrate, 0.2844g stannous chloride, 1g sepiolite powder (D50=9μm) and 40mL of deionized water and 5mL of absolute ethanol are mixed to prepare a slurry, Place the container containing the slurry in an ultrasonic cleaner for continuous ultrasonication.

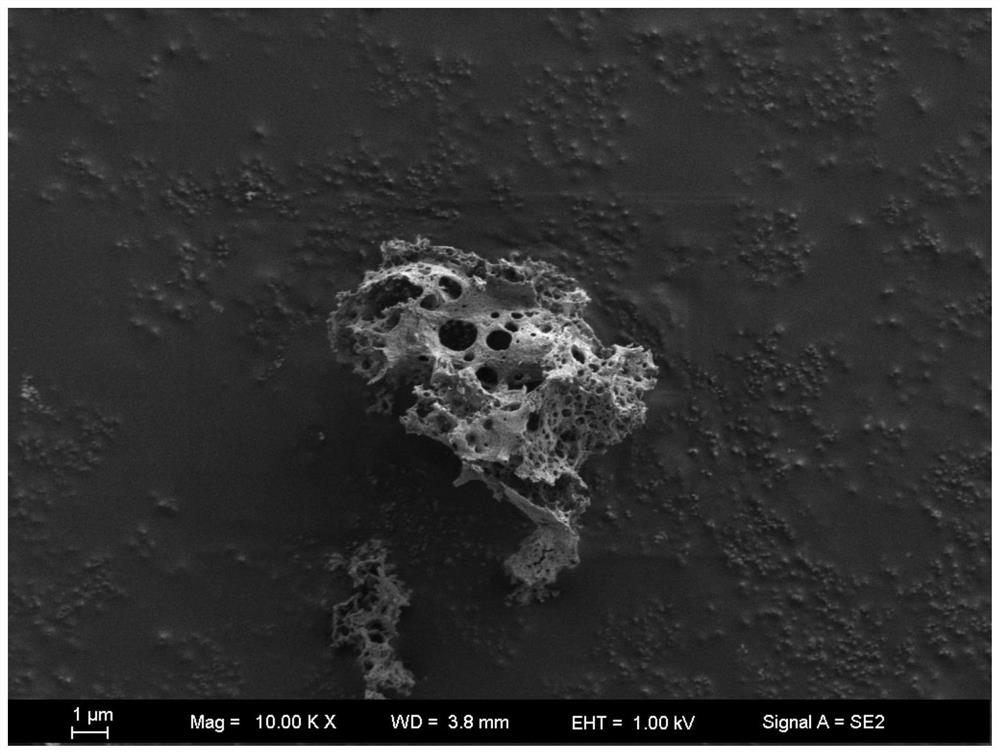

[0059] Spread the hole-boring base material after the above pret...

Embodiment 2

[0082] The slurry was prepared by mixing 0.906g copper nitrate trihydrate, 13.026g cerium nitrate hexahydrate, 0.2844g stannous chloride, 0.5g sepiolite powder (D50=9μm), 40mL deionized water and 5mL absolute ethanol , the remaining steps are the same as in Example 1, and the catalyst obtained is marked as CCS-SEP-mb-2. During the wetting process, the contact angle θ of the test slurry on the surface of the boring substrate was <20°.

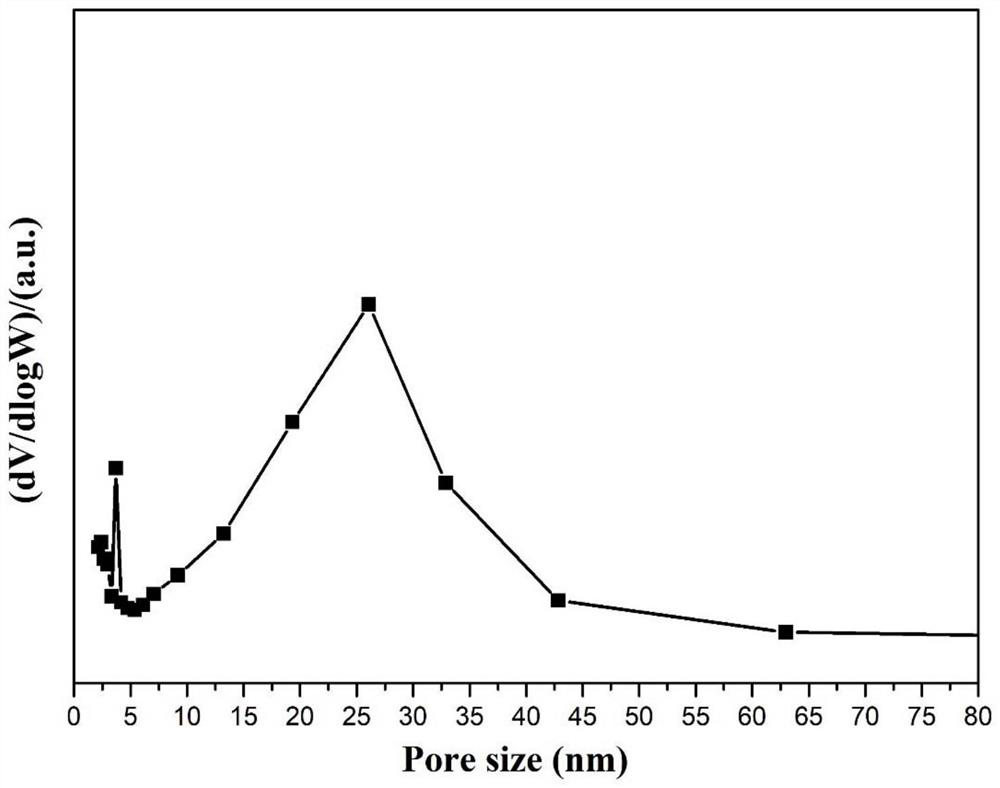

[0083] SEM results showed that the above catalyst had a similar microscopic morphology to the sample in Example 1. The specific surface area of the sample measured by BET analysis is 75.6m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com