Rapidly-curable environment-friendly waterproof material and processing technology thereof

A waterproof material and rapid curing technology, applied in the processing technology of environmentally friendly waterproof materials and the field of environmentally friendly waterproof materials, can solve the problems of high production cost, environmentally friendly aging resistance and poor weather resistance, and achieve the effect of avoiding pollution and good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

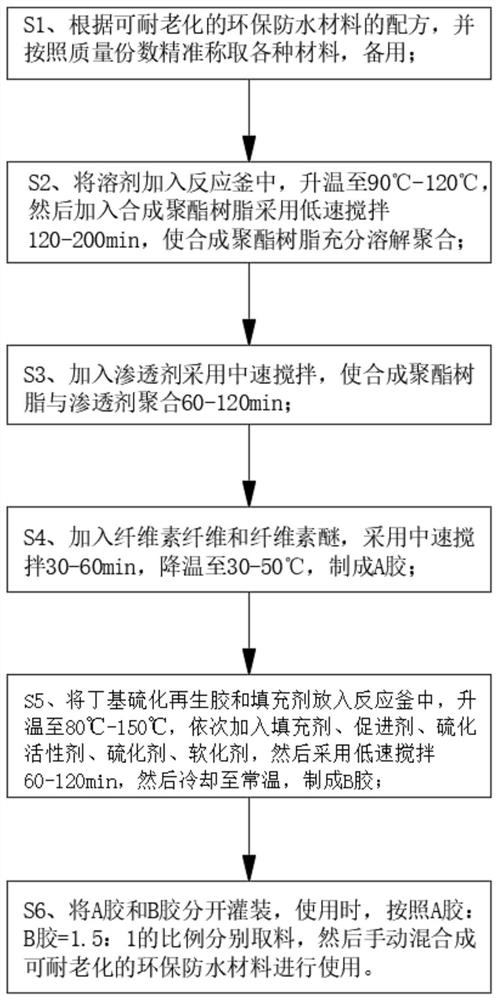

[0033] The present invention provides such figure 1As shown, a rapidly curable environmentally friendly waterproof material and its processing technology, wherein the formula of the rapidly curable environmentally friendly waterproof material includes: synthetic polyester resin, butyl vulcanized reclaimed rubber, filler, accelerator, vulcanization activity agent, vulcanizing agent, softening agent, penetrating agent, cellulose fiber, cellulose ether and conjugated porous microspheres; wherein, the butyl vulcanized reclaimed rubber is made of resin cross-linked vulcanized capsules and butyl waste rubber in high-energy rays Interacting under radiation under the influence of chain breaks in the interior of the butyl waste rubber, specifically: cutting, coarsely crushing, finely crushing, and pulverizing the resin-crosslinked vulcanization capsule and butyl waste rubber at room temperature , tableting, and electron beam radiation degradation process, which is characterized in that...

Embodiment 2

[0043] On the basis of Example 1, the conjugated porous microspheres in the components of the rapidly curable environmentally friendly waterproof material are replaced with the same amount of metal-organic frameworks.

[0044] The preparation method of the metal-organic framework is to mix ferric nitrate and pure water evenly at a mass ratio of 1:10, add 2-aminoterephthalic acid 0.9 times the mass of ferric nitrate, and then add 0.05 times the mass of ferric nitrate Hydrofluoric acid with a fraction of 40%, stirred at 20°C and 800r / min for 30min, transferred to a reaction kettle with a polytetrafluoroethylene substrate, reacted at 200°C for 7h, cooled to 20°C, and centrifuged. -Wash with dimethylformamide and absolute ethanol three times respectively, then soak in absolute ethanol at 60°C for 20 hours, cool to 20°C, filter, and dry at -10°C, 5Pa for 6 hours to obtain a metal-organic framework.

Embodiment 3

[0046] On the basis of Example 1, the conjugated porous microspheres are removed from the components of the rapidly curable environmentally friendly waterproof material.

[0047] Effect example

[0048] Table 1 below shows the analysis results of the waterproof performance and aging resistance of the rapidly curable environmentally friendly waterproof materials of Examples 1 to 3 of the present invention.

[0049] Table 1

[0050] waterproof rate curing time Example 1 99.9% 7.3h Example 2 96.6% 10.2h Example 3 96.2% 13.5h

[0051] From the comparison of the experimental data of Example 1 and Example 2 in Table 1, it can be found that the waterproof rate and performance retention rate of Example 1 are larger than that of Example 2, which shows that the metal-organic framework is stacked and polymerized to form conjugated porous microspheres. During use, it can absorb the long-chain organic matter in A glue and B glue into the pores, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com