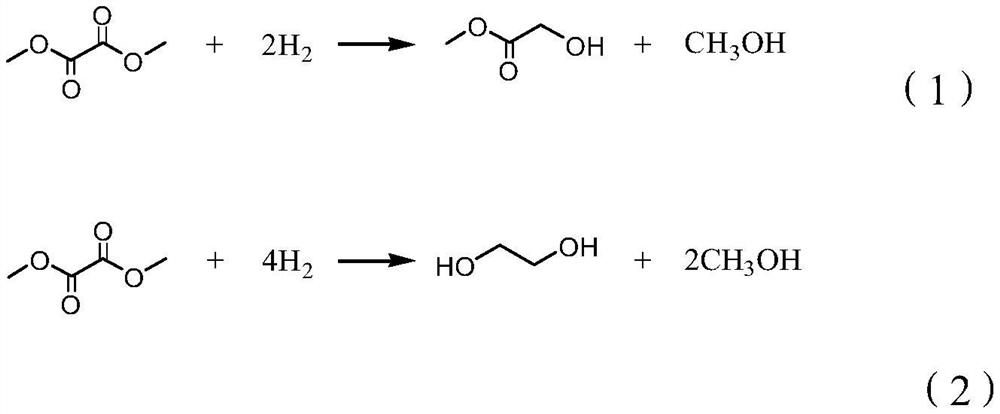

Dimethyl oxalate hydrogenation catalyst as well as preparation method and application thereof

A technology of dimethyl oxalate and hydrogenation catalyst, which is applied in the direction of carboxylate preparation, metal/metal oxide/metal hydroxide catalyst, heterogeneous catalyst chemical elements, etc., which can solve the complicated process and complicated preparation method And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

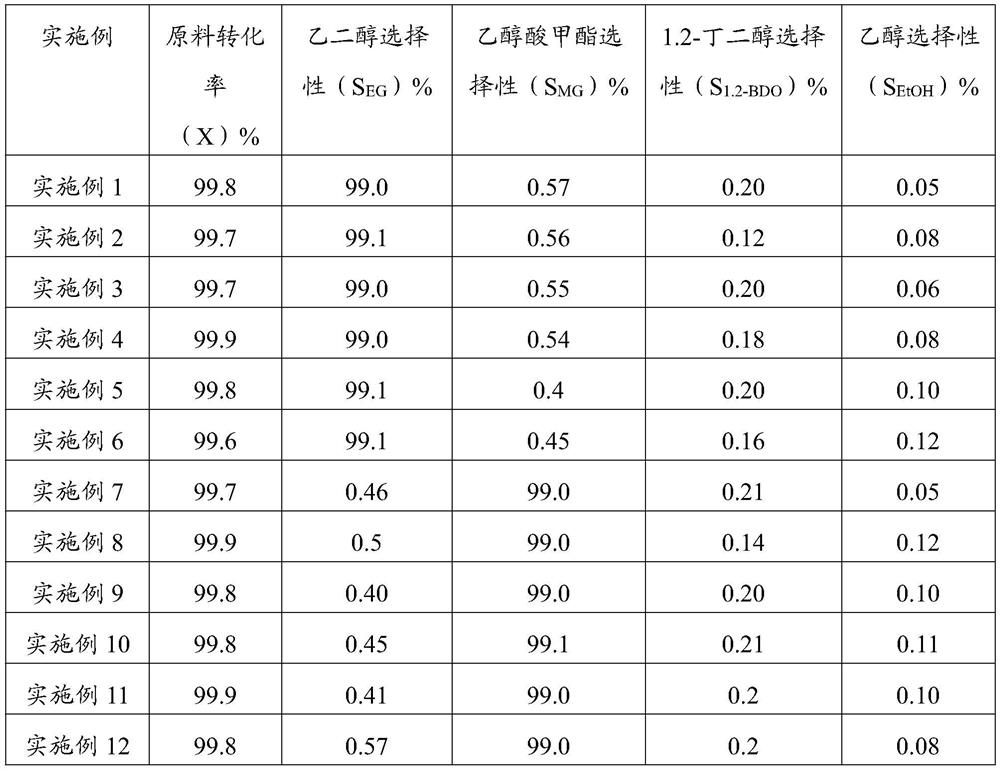

Examples

preparation example Construction

[0043] The present inventor also provides the preparation method of this catalyzer, adopts ammonia distillation method (supporting copper operation) and impregnation method (supporting M operation) to synthesize this catalyzer, specifically comprises the following steps:

[0044] 1), at 20-30°C, an aqueous solution made of soluble copper salt; after adding ammonia water, it becomes a copper-ammonia complex solution

[0045] 2), at 20-30°C, add silica sol and cuproammonia solution dropwise at the same time; after the dropwise addition is completed, heat up to deamination until the pH value of the slurry in the kettle is 6-7;

[0046] 3), filtering, washing the filter cake with water, drying, and roasting to obtain the roasted precursor CuO / SiO 2 ;and

[0047] 4) Configure a co-active component metal salt solution with a mass fraction of 0.1-5%, and quickly add the roasted precursor CuO / SiO 2 , impregnated at room temperature for 2-24h, dried, roasted, and reduced to obtain a ...

Embodiment 1

[0062] Precursor preparation: Weigh 60.74g of copper nitrate trihydrate and 265g of water to dissolve, add 205g of 20.88% ammonia water to form a copper-ammonia complex solution, weigh 533.3g of 15% silica sol solution, and co-feed at 10g / min The method is to drop the two materials of copper ammonia complex solution and silica sol solution into the kettle respectively. After the dropping is completed, the temperature is raised to deamination until the pH value of the slurry in the kettle is between 6-7, filtered, and dried at 120°C for 12h, 400°C After calcination at ℃ for 6h, the catalyst precursor 20.0% CuO / SiO was obtained 2 (Meaning: CuO mass content accounts for the precursor (CuO and SiO 2 ) percentage of the total mass, the following examples have the same meaning; in addition, the catalyst precursor here is also referred to as "calcined precursor" in this application).

[0063] Catalyst preparation: Weigh 0.51g of platinum chloride to prepare an aqueous solution with ...

Embodiment 2

[0066] Precursor preparation: Weigh 75.93g of copper nitrate trihydrate and 545g of water to dissolve, add 267g of 20.88% ammonia water to configure a copper-ammonia complex solution, weigh 883g of 8.5% silica sol solution, and feed it at 10g / min Add copper ammonia complex solution and silica sol solution dropwise. After the dropwise addition, raise the temperature to deamination until the pH value of the slurry in the kettle is between 6-7, filter, dry at 120°C for 12 hours, and roast at 400°C for 6 hours. Obtain catalyst precursor 25.0wt% CuO / SiO 2 .

[0067] Catalyst preparation: Dissolve 0.56g of palladium chloride in 100g of 1% hydrochloric acid aqueous solution, add 20g of precursor, and age at room temperature for 12h; dry at 120°C for 12h, and roast at 400°C for 4h to obtain a catalyst with an atomic ratio of Pd and Cu of 0.05. Catalyst 2: Contains 1.93 wt% PdO-25.0 wt% CuO.

[0068] Ethylene glycol synthesis: place the catalyst in a fixed-bed reactor, set the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com