Copper alloy film, protection layer after service based on copper alloy film and preparation method

A copper alloy and protective layer technology, applied in the field of electronic thin film materials, can solve the problems of copper electrochemical migration, failure of electronic equipment, incomplete coverage of silver plating, etc., to simplify the process, improve service life, and inhibit electrochemical migration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Copper-molybdenum alloy is electrodeposited on the printed circuit board, and then the alloy coating is layered to form defects such as corrosion and migration damage to protect the metal copper during service, so as to improve circuit reliability. The specific steps include:

[0036] 1) Prepare electroplating solution: 87g / L citric acid (C 6 h 8 o 7 ), 40g / L copper sulfate (CuSO 4 ), 160g / L sodium molybdate (Na 2 MoO 4 ·H 2 O) and 0.2g / L sodium lauryl sulfate (C 12 h 25 SO 4 Na) was added into deionized water and stirred evenly to obtain the electroplating solution;

[0037] 2) Pretreatment of electroplating: use 1500, 2000 mesh metallographic sandpaper to polish the surface of the copper plate smooth, and clean it with deionized water and absolute ethanol, and then dry to obtain the substrate to be plated;

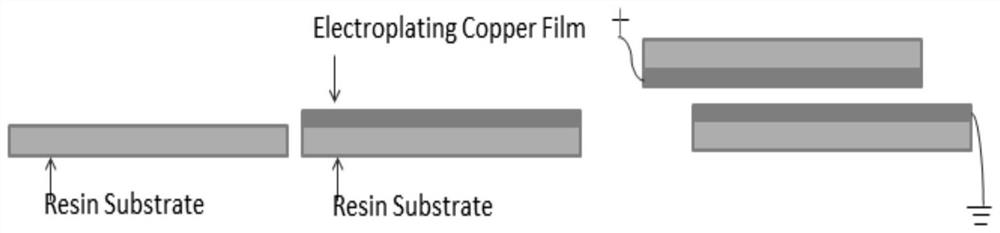

[0038] 3) Electrodeposition: use the substrate to be plated prepared in step 2) as the cathode, and the carbon plate as the anode, put the anode and the ...

Embodiment 2

[0045] The copper-chromium alloy formed by the method of magnetron sputtering on the circuit board, the specific steps include:

[0046] During the magnetron sputtering process, the purity of the Cu target material is 99.99%, the purity of the Cr target material is 99.9%; the basic vacuum degree is 10 -7 Torr, maintain argon protection during the sputtering process, and keep the argon pressure at 10 -3 Torr; a Cu-4.2Cr film with a mass percent content of 4.2% was obtained.

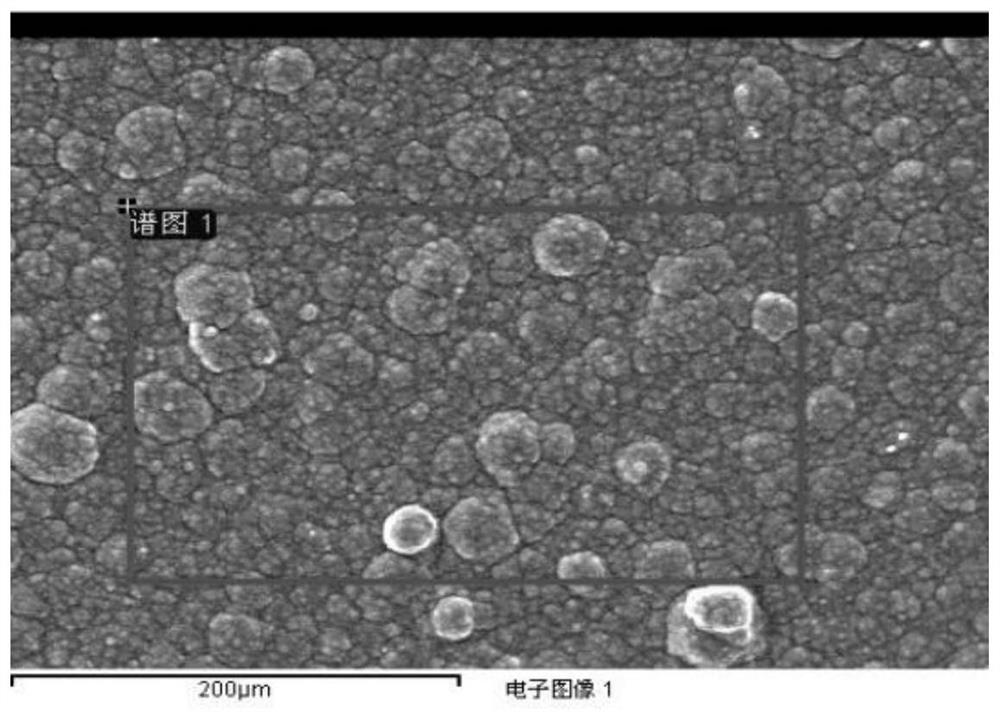

[0047] see Figure 7 The XRD results show that the peak is basically copper, but the width of the peak increases, which should be that Cr is physically mixed with Cu during the sputtering process.

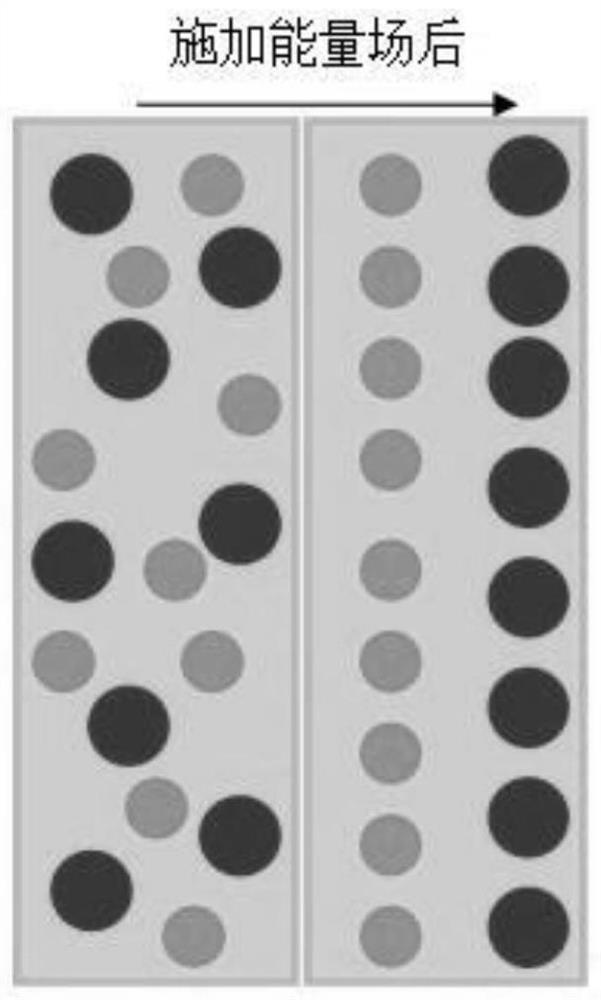

[0048] Since the structure is thermodynamically unstable, further applying a temperature field to the film, that is, after thermal aging treatment at a temperature of 60°C for 12 hours, Cr will precipitate on the surface of Cu at this time, forming a thin continuous Cr layer, which is to protect the Cu layer...

Embodiment 3

[0050] Since the cold rapid solidification largely expands the solid solubility of Co in the Cu phase from 7.46% to 20% under equilibrium conditions, Cu-Co of different compositions has positive mixing enthalpy, and there is a metastable phase in the phase diagram Solubility gap, which makes the solid solubility of Cu-Co alloy have a huge space under supersaturated conditions.

[0051] Electrodepositing a copper-cobalt alloy coating on a copper plate comprises the following steps:

[0052] 1) Preparation of electroplating solution: take 0.01mol of copper sulfate, 0.7mol of cobalt sulfate and 0.2mol of sodium acetate and add them into deionized water and stir evenly to prepare the electroplating solution;

[0053] 2) Pretreatment of electroplating: use 1500, 2000 mesh metallographic sandpaper to polish the surface of the copper plate smooth, and clean it with deionized water and absolute ethanol, and then dry to obtain the substrate to be plated;

[0054] 3) Electrodeposition:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com