Preparation process of emulsified DHA oil

A preparation process and technology of pre-emulsion, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of unfriendly children or the elderly, limited amount of DHA added, etc., to enhance bioavailability , reduce energy intake, maintain the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

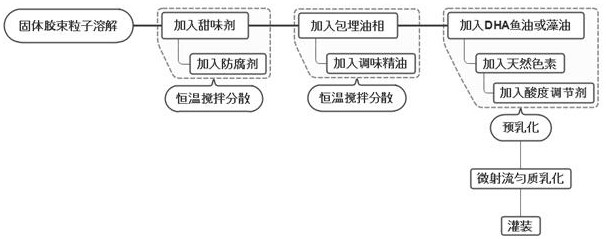

Method used

Image

Examples

Embodiment 1

[0024] The xanthan gum that is 0.5% by mass fraction is joined in ultrapure water, 38 degrees Celsius stirs 15min with 1kr / min constant temperature, in the process of constant temperature stirring, add mass fraction is 28% xylitol and mass fraction is 0.06% potassium sorbate, stirring continuously for 12min. Add 20% corn oil by volume and 25% linseed oil by volume, continue stirring at constant temperature for 5 minutes, then add 2% sweet orange oil by volume, and stir for 10 minutes at constant temperature. Continue to add 18% fish oil by volume and stir for 10 minutes, continue to add 0.02% natural carotene and 0.2% citric acid by volume, and stir for 5 minutes. Use a colloid mill with a speed of 6500r / min, a crushing degree of about 22 μm, and rotate for 6 minutes to prepare a pre-emulsion. The pre-emulsion is processed 6 times by a 120Mpa micro-fluidic homogenizer to obtain a milkshake-like emulsified DHA product.

[0025] Particle size:

[0026] The average particle di...

Embodiment 2

[0032]The seaweed polysaccharide that is 0.8% by mass is added to ultrapure water, 35 degrees Celsius with 0.8kr / min constant temperature stirring 18min, in the process of constant temperature stirring, add the xylitol that the mass fraction is 26% and the mass fraction is 0.06% potassium sorbate, stirring continuously for 10 minutes. Add 22% corn oil by volume and 5% walnut oil by volume, and continue stirring at constant temperature for 5 minutes, then add 1.8% lemon oil by volume and 0.1% menthol, and stir for 10 minutes at constant temperature. Continue to add 22% fish oil by volume and stir for 8 minutes, continue to add 0.05% natural carotene and 0.15% citric acid by volume, and stir for 5 minutes. Use a colloid mill with a rotating speed of 5800r / min, a crushing degree of about 18 μm, and rotate for 8 minutes to prepare a pre-emulsion. The pre-emulsion is processed 5 times by a 90Mpa micro-fluidic homogenizer to obtain a milkshake-like emulsified DHA product.

[0033]...

Embodiment 3

[0036] Add 0.5% xanthan gum and 0.1% gum arabic into ultrapure water at 40°C and stir at a constant temperature of 1 kr / min for 9 minutes, and add 24% erythrose in the process of constant temperature stirring Alcohol and potassium sorbate with a mass fraction of 0.06% were stirred continuously for 10 minutes. Add 28% linseed oil by volume, and keep stirring at constant temperature for 6 minutes, then add 2% lemon oil and 0.3% dill seed oil by volume, and stir for 8 minutes at constant temperature. Continue to add 30% fish oil by volume and stir for 12 minutes, continue to add 0.05% natural carotene and 0.15% citric acid by volume, and stir for 5 minutes. Use a colloid mill with a speed of 6200r / min, a crushing degree of about 20 μm, and rotate for 6 minutes to prepare a pre-emulsion. The pre-emulsion is processed 6 times by a 120Mpa micro-fluidic homogenizer to obtain a milkshake-like emulsified DHA product.

[0037] Absorption Utilization:

[0038] The prepared emulsion DH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com