Powder coating and preparation method and application thereof

A powder coating and coating technology, used in powder coatings, fireproof coatings, coatings, etc., can solve the problems of high cost and difficult to meet the large demand of high-end buildings, and achieve super weather resistance, excellent adhesion, and uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

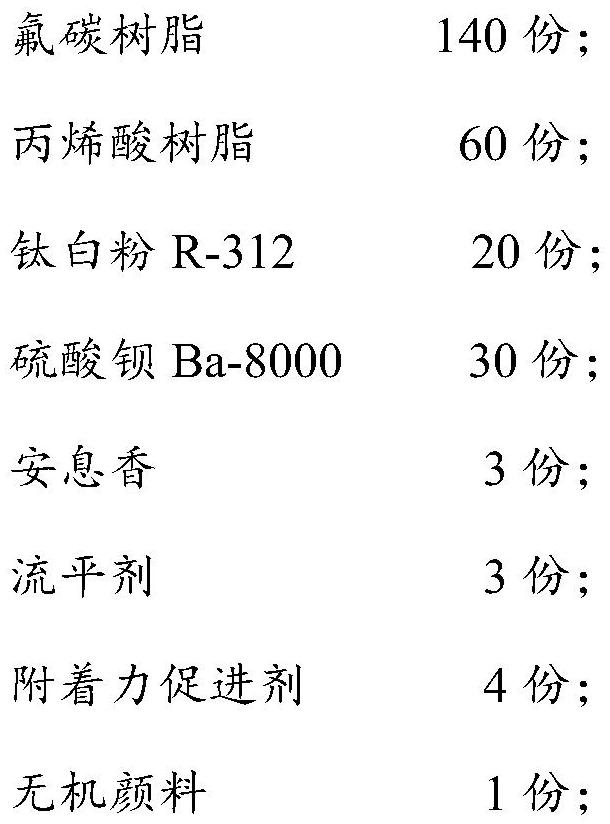

[0083] This embodiment is a powder coating and its preparation method.

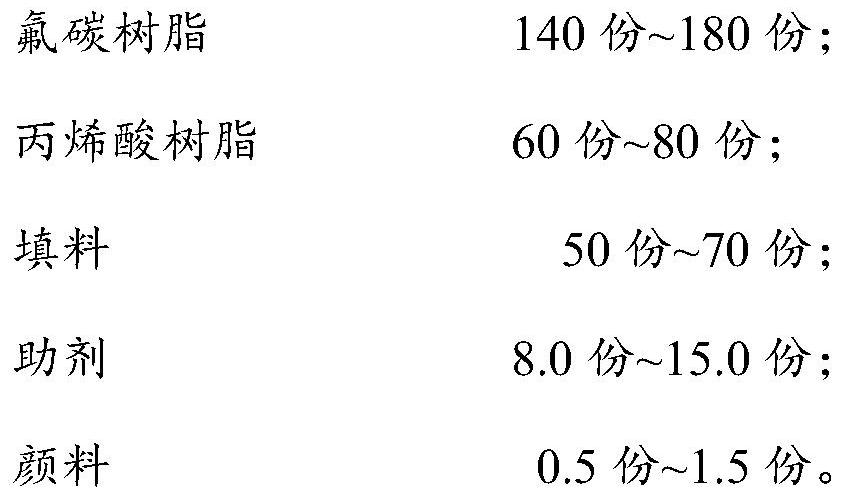

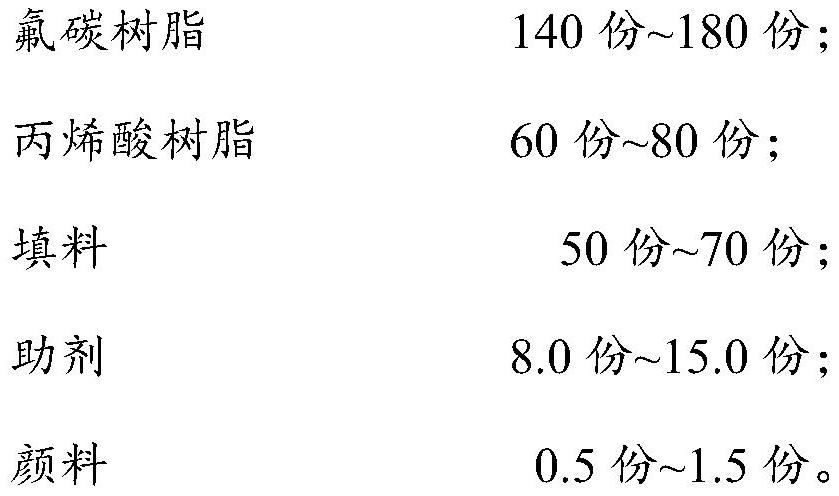

[0084] The powder coating of the present embodiment is made by the preparation raw material of following mass parts:

[0085]

[0086] Among them, the fluorocarbon resin is a homopolymer of vinylidene fluoride with a purity ≥ 99.99%. The melt index of the fluorocarbon resin is 8g / 10min to 25g / 10min, the melting point is 165°C to 175°C, and the bulk density is 200g / L to 500g / L.

[0087] The acid value of the acrylic resin is ≤2.0mgKOH / g; the glass transition temperature of the acrylic resin is 60°C; the intrinsic viscosity of the acrylic resin is 0.40.

[0088] The preparation method of the present embodiment powder coating is made up of the following steps:

[0089] S1. Weigh acrylic resin, titanium dioxide R-312, barium sulfate Ba-8000, benzoin, leveling agent, adhesion promoter and inorganic pigment in a mixing tank, mix thoroughly and crush for 2 minutes to obtain a mixture.

[0090] S2. Extruding...

Embodiment 2

[0094] This embodiment is a powder coating and its preparation method.

[0095] The powder coating of the present embodiment is made by the preparation raw material of following mass parts:

[0096]

[0097]

[0098] Among them, the fluorocarbon resin is a homopolymer of vinylidene fluoride with a purity ≥ 99.99%. The melt index of the fluorocarbon resin is 8g / 10min to 25g / 10min, the melting point is 165°C to 175°C, and the bulk density is 200g / L to 500g / L.

[0099] The acid value of the acrylic resin is ≤2.0mgKOH / g; the glass transition temperature of the acrylic resin is 60°C; the intrinsic viscosity of the acrylic resin is 0.40.

[0100] The preparation method of the present embodiment powder coating is made up of the following steps:

[0101] S1. Weigh acrylic resin, titanium dioxide R-312, barium sulfate Ba-8000, benzoin, leveling agent, adhesion promoter and inorganic pigment in a mixing tank, mix thoroughly and crush for 2 minutes to obtain a mixture.

[0102] S...

Embodiment 3

[0106] This embodiment is a powder coating and its preparation method.

[0107] The powder coating of the present embodiment is made by the preparation raw material of following mass parts:

[0108]

[0109]

[0110] Among them, the fluorocarbon resin is a homopolymer of vinylidene fluoride with a purity ≥ 99.99%. The melt index of the fluorocarbon resin is 8g / 10min to 25g / 10min, the melting point is 165°C to 175°C, and the bulk density is 200g / L to 500g / L.

[0111] The acid value of the acrylic resin is ≤2.0mgKOH / g; the glass transition temperature of the acrylic resin is 60°C; the intrinsic viscosity of the acrylic resin is 0.40.

[0112] The preparation method of the present embodiment powder coating is made up of the following steps:

[0113] S1. Weigh acrylic resin, titanium dioxide R-312, barium sulfate Ba-8000, benzoin, leveling agent, adhesion promoter and inorganic pigment in a mixing tank, mix thoroughly and crush for 2 minutes to obtain a mixture.

[0114] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com