Polyolefin-based microporous film, laminate, and nonaqueous electrolyte secondary battery using same

A technology of microporous membrane and polyolefin, which is applied in the direction of non-aqueous electrolyte batteries, secondary batteries, non-aqueous electrolytes, etc., can solve the problems of shortened charging and discharging time, reduced battery capacity, and reduced number of ions, achieving excellent strength, The effect of improving the capacity maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] (a) Preparation process of polyolefin resin solution

[0090] The polyolefin-based resin used in the embodiment of the present invention is heated and dissolved in a plasticizer to prepare a polyolefin-based resin solution. The plasticizer is not limited as long as it is a solvent that can sufficiently dissolve the polyolefin-based resin. Since stretching at a relatively high ratio is possible, the solvent is preferably liquid at room temperature.

[0091] Examples of solvents include aliphatic, cycloaliphatic or aromatic hydrocarbons such as nonane, decane, decalin, p-xylene, undecane, dodecane, and liquid paraffin, and minerals having boiling points corresponding to them. Oil fractions, and phthalates that are liquid at room temperature, such as dibutyl phthalate and dioctyl phthalate. In order to obtain a gel-like sheet with a stable liquid solvent content, it is preferable to use a non-volatile liquid solvent such as liquid paraffin.

[0092] The ratio of the solv...

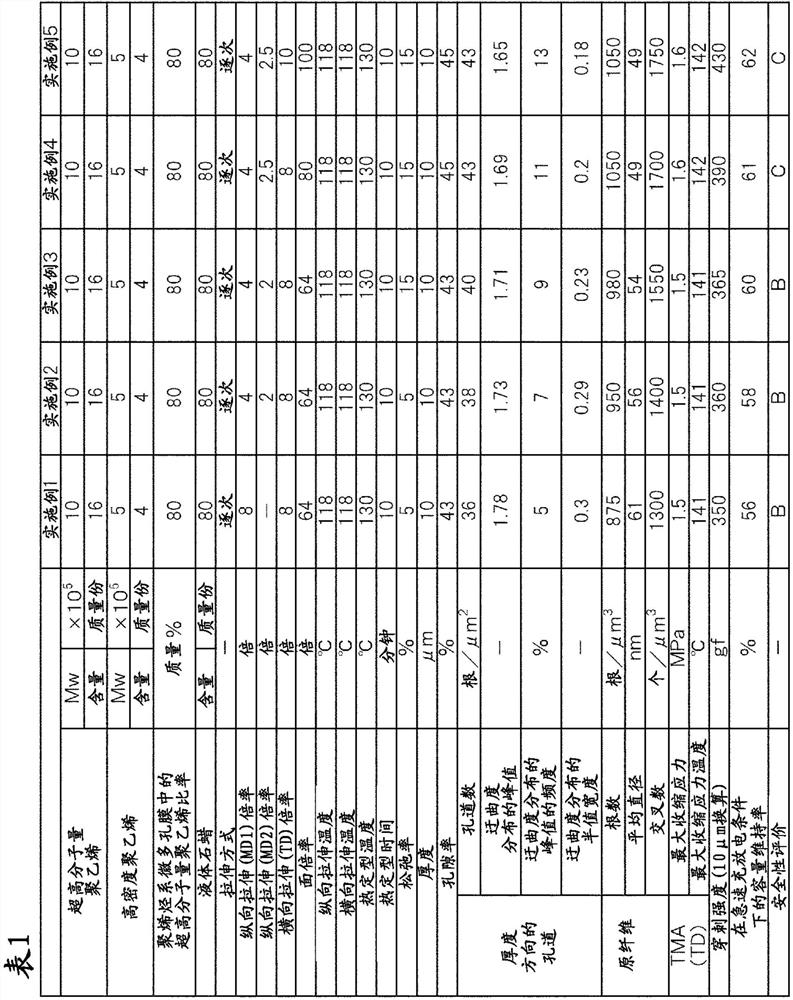

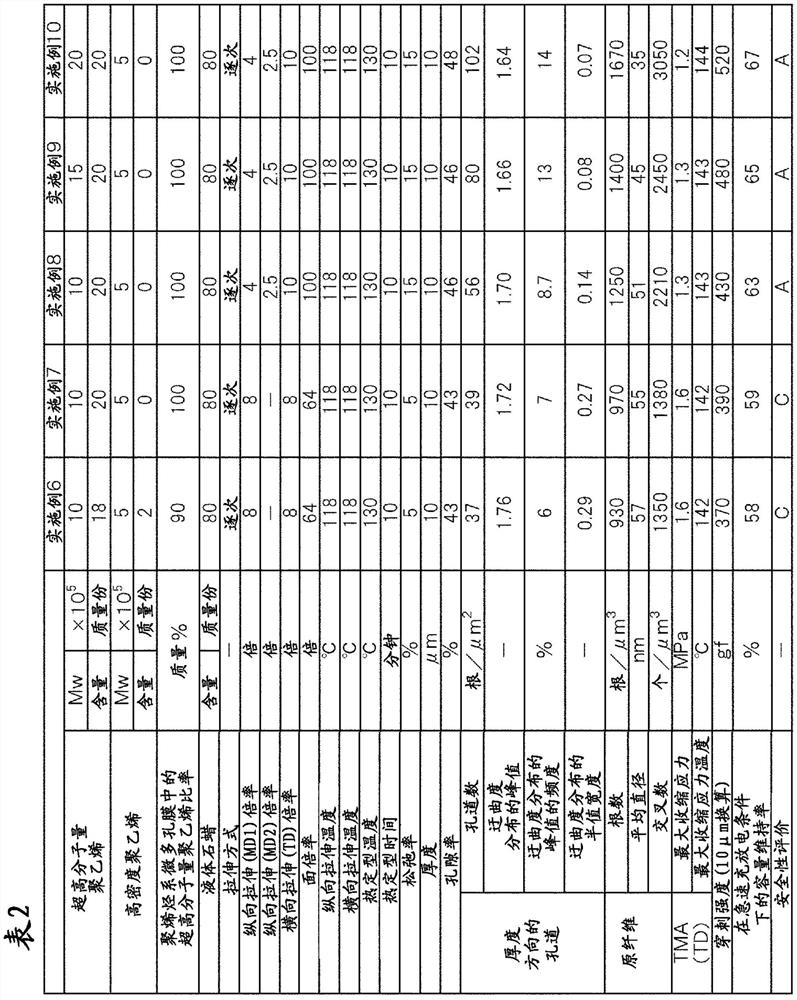

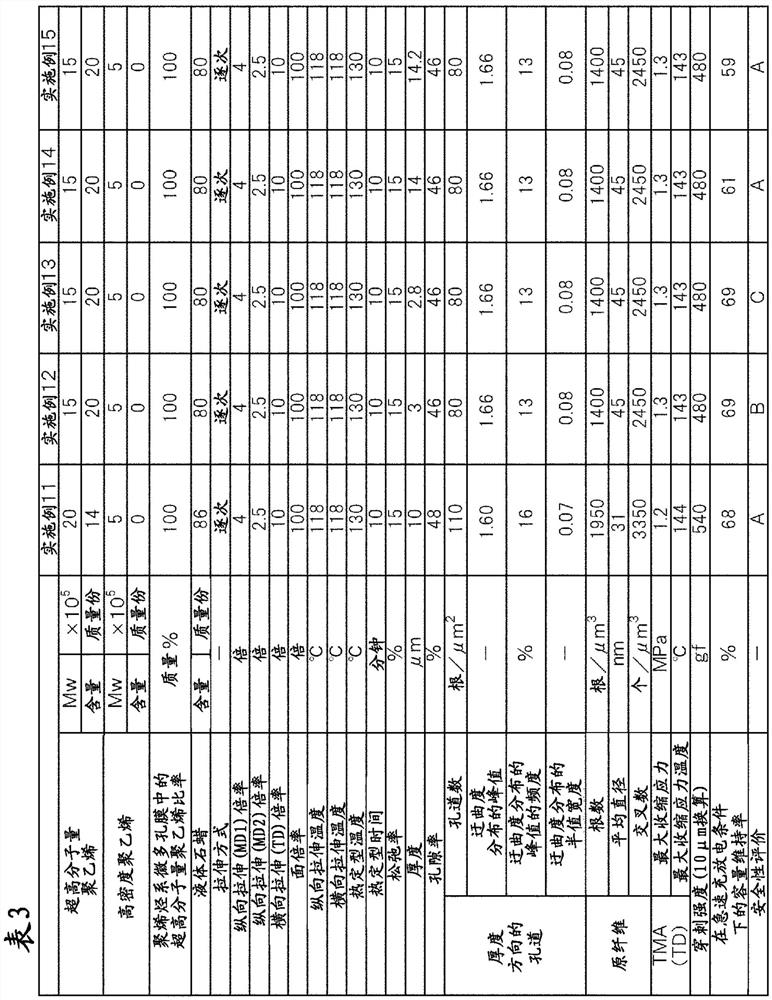

Embodiment 1

[0198] Use a weight average molecular weight (Mw) of 10×10 5 The ultra-high molecular weight polyethylene and the weight average molecular weight (Mw) are 5×10 5 high-density polyethylene as raw material. Add 80 parts by mass of liquid paraffin to 16 parts by mass of ultra-high molecular weight polyethylene and 4 parts by mass of high-density polyethylene, and then add and mix 0.5 parts by mass of 2,6-di-tert-butyl based on the total mass of polyethylene-based resins Base-p-cresol and 0.7 mass parts of tetrakis [methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate] methane as antioxidant, prepare polyethylene resin solution . In addition, when the mass of all polyethylene-type resins was 100 mass %, the ratio of the ultrahigh molecular weight polyethylene was 80 mass %. Since most of liquid paraffin and antioxidants are removed in the production process, in the present invention, the ratio of ultra-high molecular weight polyethylene when the mass of all polyethylene r...

Embodiment 2

[0203] For stretching in the longitudinal direction (MD direction) by a roll stretching machine, the first stage (MD1) is set to 118°C, 4 times (described in the table as longitudinal stretch (MD1)), the second stage (MD2 ) was set to 118° C. and 2 times (in the table, it is described as longitudinal stretching (MD2)), and stretching was carried out in two stages, and a polyolefin-based microporous membrane was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Puncture strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com