Offshore deepwater intertidal zone type multi-nutrient-layer aquaculture net field and aquaculture method

A technology for aquaculture and aquaculture nets, applied in the fields of botanical equipment and methods, fish farming, seaweed cultivation, etc., can solve the problems of poor load performance, difficult to control dynamic load, easy to break, etc., and achieve strong wind and wave resistance and stability. , reduce management costs, buffer the effect of frequent shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

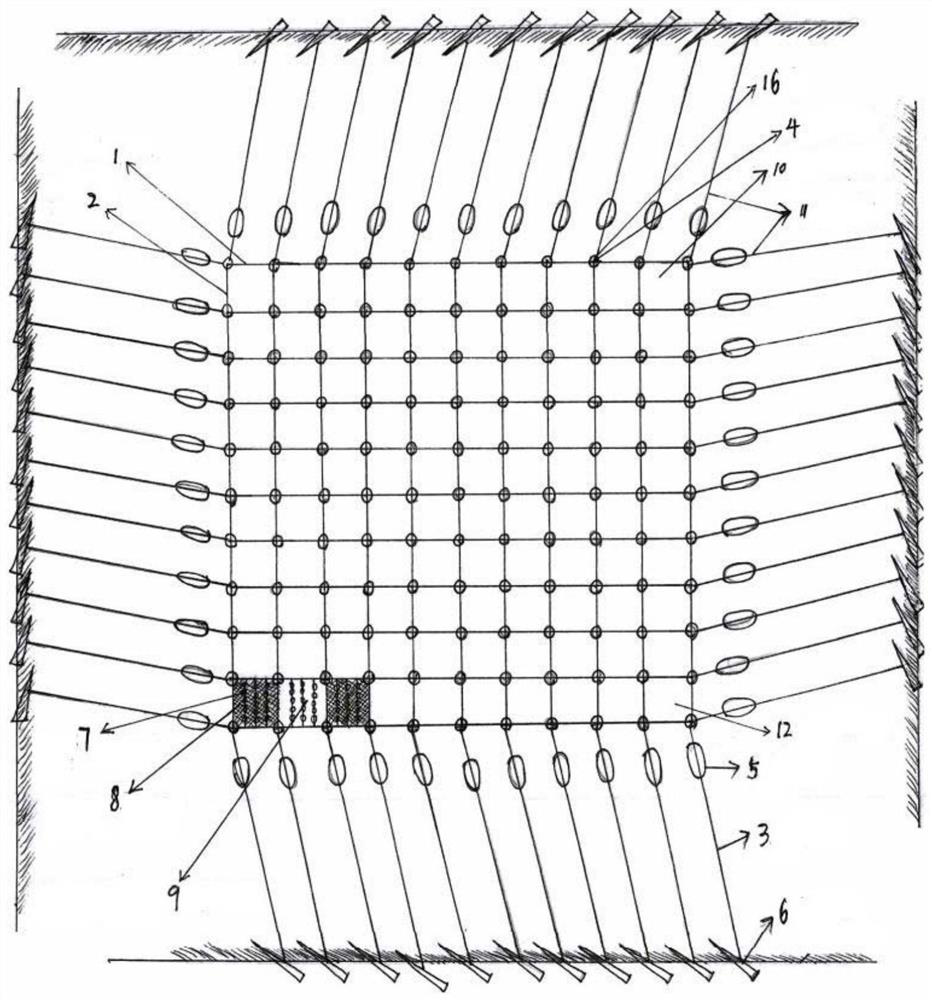

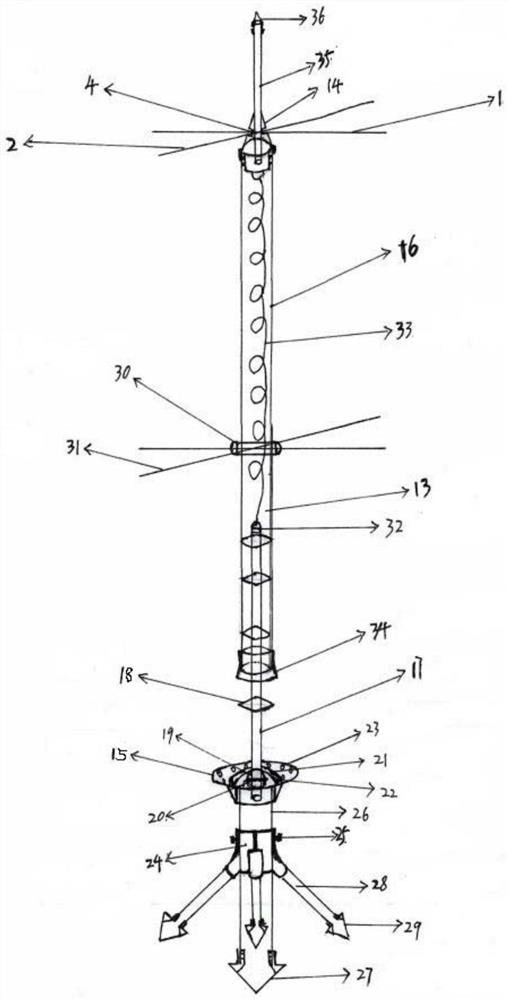

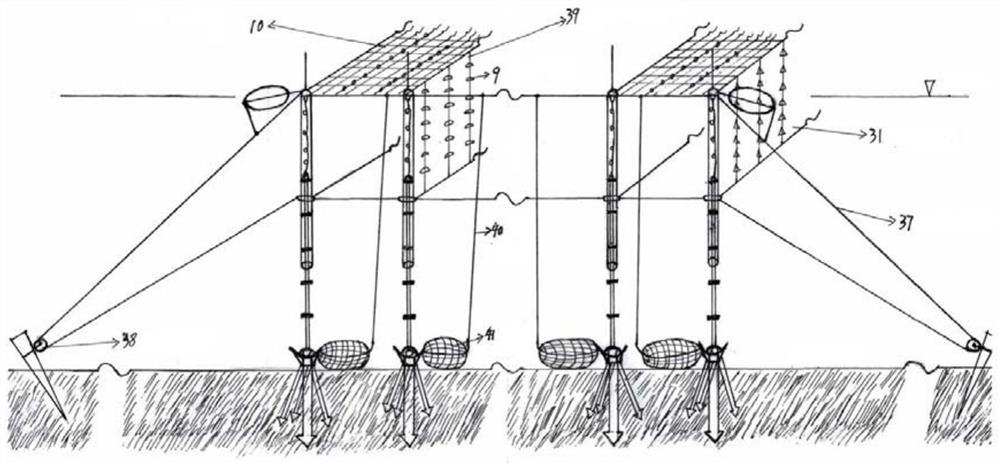

[0068] Example 1, refer to Figure 1 to Figure 5 , an offshore deep-water intertidal zone type multi-trophic layer aquaculture net field, including the upper sea surface aquaculture net field: a plurality of small rectangular meshes 12 are formed by the horizontal float 1 and the vertical float 2 perpendicular to each other, and bundled together. At the cross point 4, each float in the rectangular net field 10 is connected to one end of the root cable 3 with the large float 5 at the side of the field, and the other end of the root cable 3 is tied to the seabed fixed pile 6, and the small rectangular meshes are arranged in parallel. Cable 7, which is then connected with a mesh curtain and pulled to flatten the algae growth base 8;

[0069]For all the intersections 4 of the "ten" character where the horizontal and vertical floats 1 and 2 are perpendicular to each other, the floating ropes and strands of the crossing points are firstly separated, and then a piece of thin rope is ...

Embodiment 2

[0070] Embodiment 2, the intertidal zone type multi-trophic aquaculture net field in the offshore deep water area described in Embodiment 1, also includes a middle-layer aquaculture net field: the clamps 30 are fastened by the bolt holes fixed in the middle and lower sections of the hollow struts 16. , connect the middle-layer breeding net field 31 with the upper-layer rectangular net field 10 through the holes, connect the upper and middle-layer breeding net fields by fixing the shellfish connecting rope 39, and string the shellfish cultured at intervals 9. The quasi-connecting rope 39 is the foundation, which is suspended and fixed for cultivation;

Embodiment 3

[0071] Embodiment 3. The intertidal zone type multi-trophic aquaculture net field in the offshore deep water area described in Embodiment 1 also includes bottom seabed culture: the bottom fixed net cage connects the rope 40, and the upper end is horizontal to the upper layer rectangular aquaculture net field 10. The float 1 or the vertical float 2 are connected, and the lower end is fastened and fixed by the peripheral hole 23 of the supporting tray 15, and the seabed culturing net cage 41 is passed through the net cage connecting rope 40 on the sea surface, and is slid to the seabed for aquaculture, or is brought to the sea surface by the seabed. manage harvest;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com