Preparation method of manganese oxide molecular sieve composite filter material for treating diclofenac in water

A technology of composite filter material and diclofenac, which is applied in chemical instruments and methods, alkali metal compounds, water/sewage treatment, etc., can solve the problems of poor removal effect and high efficiency, and achieve high-efficiency purification of water quality. The preparation method is simple and effective. The effect of removing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of manganese oxide molecular sieve composite filter material for treating diclofenac in water, is characterized in that, carries out as follows:

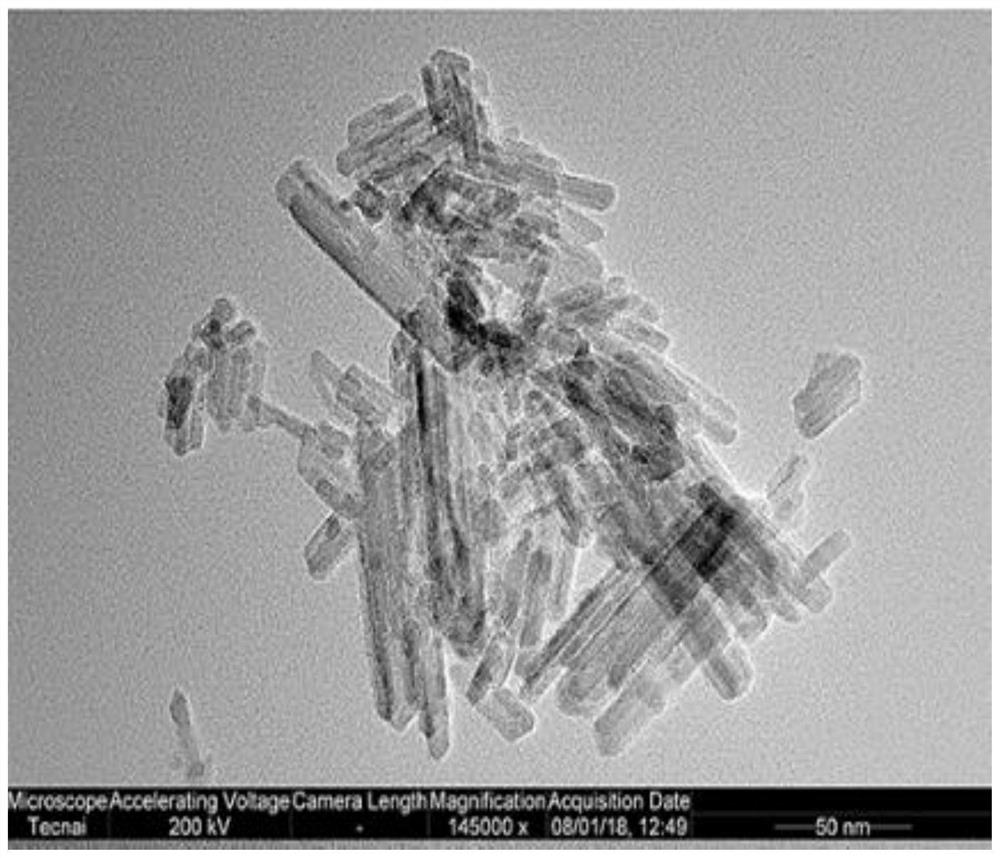

[0032] (1) Synthesis of manganese oxide molecular sieve, mix potassium permanganate and manganese acetate according to the molar ratio of 2:3 and grind them evenly in a mortar, pour the resulting mixed powder into a capped glass bottle, and place it at 80°C After 4 hours under ambient conditions, the obtained black product was washed 3 times with deionized water and suction-filtered, and finally the obtained material was dried at 80° C. for 12 hours to obtain a manganese oxide molecular sieve.

[0033] (2) Synthesis of amino-modified manganese oxide molecular sieve composite filter material, 1.5g manganese oxide molecular sieve was added into 300mL volume concentration of 50% ethanol aqueous solution, ultrasonic at room temperature for 0.5 hours, 35mL ammonia water was added, and stirred at 60°C fo...

Embodiment 2

[0035] A kind of preparation method of manganese oxide molecular sieve composite filter material for treating diclofenac in water, is characterized in that, carries out as follows:

[0036] (1) For the synthesis of manganese oxide molecular sieve, mix potassium permanganate and manganese acetate according to the molar ratio of 2.5:3 and grind them evenly in a mortar, pour the resulting mixed powder into a capped glass bottle, and place it at 85°C After 5 hours under ambient conditions, the obtained black product was washed 5 times with deionized water and suction-filtered, and finally the obtained material was dried at 85° C. for 12 hours to obtain a manganese oxide molecular sieve.

[0037] (2) Synthesis of amino-modified manganese oxide molecular sieve composite filter material, add 1.5g manganese oxide molecular sieve to 300mL volume concentration of 55% ethanol aqueous solution, ultrasonic at room temperature for 0.5 hour, add 35mL ammonia water, stir at 60°C for 24 hours (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com