Ammonium salt dispersing agent for refinery fractionation device as well as preparation method and application of ammonium salt dispersing agent

A technology of fractionation device and dispersant, which is applied in the distillation control/regulation of hydrocarbon oil, corrosion prevention during distillation, petroleum industry, etc. It can solve the problems of large operation fluctuations, inability to effectively inhibit corrosion under ammonium salt scale, and high energy consumption for water washing, etc. problems, to achieve the effect of solving corrosion, stable and long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

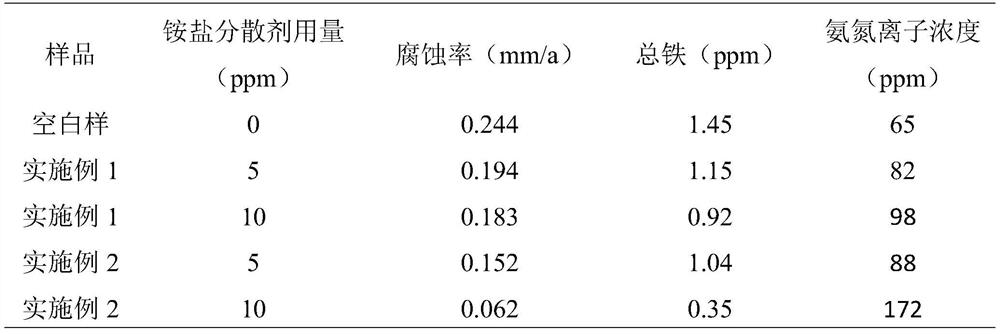

Examples

Embodiment 1

[0019] An ammonium salt dispersant for refinery fractionation unit, which consists of the following components in mass percentage: 35% of clean dispersant, 5% of phase transfer agent, 10% of gas phase surfactant, 5% of passivator, and 3% of organic amine , Ethylene oxide modified imidazoline 5%, solvent balance.

[0020] Wherein, the cleaning and dispersing agent is polyisobutylamine; the phase transfer agent is tetrabutylammonium bisulfate and trioctylmethylammonium chloride, and the mass fractions are 50% and 50% respectively; the gas-phase surfactant is coconut acid monoethanol Disodium amide sulfosuccinate monoester; passivator is trivalent chromium aluminum passivator; organic amine is diisopropanolamine and triisopropanolamine, and the mass fraction is 50% and 50% respectively; solvent oil is diesel fuel.

[0021] It is used as ammonium salt dispersant in fractionation unit of refinery, including the following steps: Weigh the raw materials according to the mass ratio, ...

Embodiment 2

[0023] An ammonium salt dispersant used in refinery fractionation unit, composed of the following components in mass percentage: 40% of clean dispersant, 4% of phase transfer agent, 12% of gas phase surfactant, 4% of passivator, 4% of organic amine , ethylene oxide modified imidazoline 6%, solvent naphtha balance.

[0024] Among them, the cleaning and dispersing agent is polyetheramine; the phase transfer agent is tetrabutylammonium bisulfate, trioctylmethylammonium chloride and dodecyltrimethylammonium chloride, and the mass fractions are 60% and 20% respectively and 20%; the vapor phase surfactant is disodium lauryl sulfosuccinate and cocoyl monoethanolamide sulfosuccinate disodium, and the mass fractions are 50%, 50% respectively; the passivator is magnesium Alloy chromium-free passivator; organic amine is N, N-dimethylethanolamine; solvent oil is aromatic oil.

[0025] It is used as ammonium salt dispersant in fractionation unit of refinery, including the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com