Equipment and method for synthesizing multi-crystal/single-crystal manganese oxide for infrared detection and magnetic sensing

An infrared detection, manganese oxide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of overflow reaction gas, particle size gap affecting the density of polycrystalline ceramics, inability to dry gel processing, etc. , to reduce the possibility of impurities, reduce the phenomenon of local agglomeration, and improve the feasibility of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

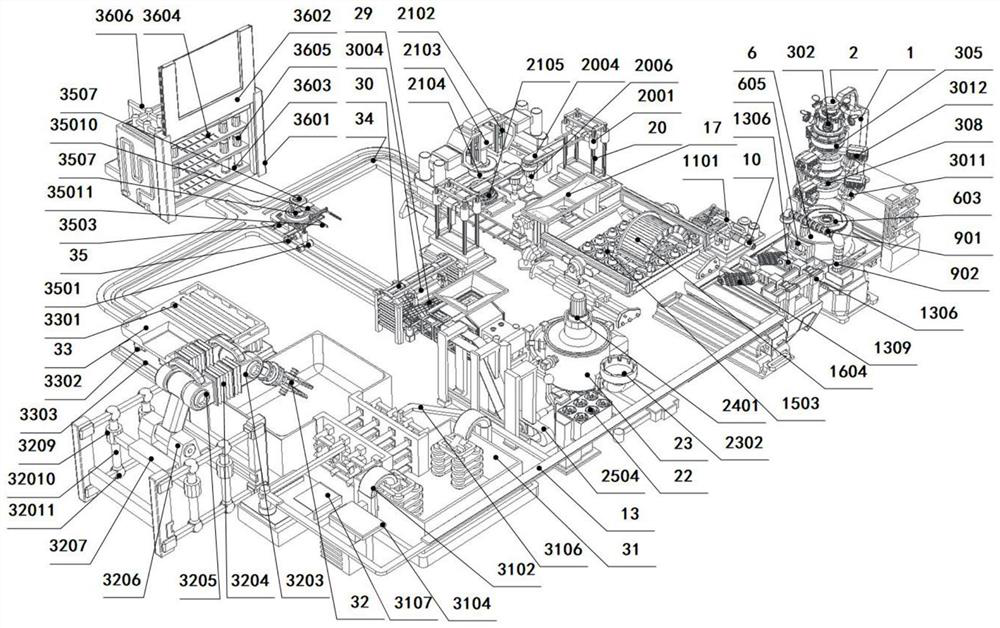

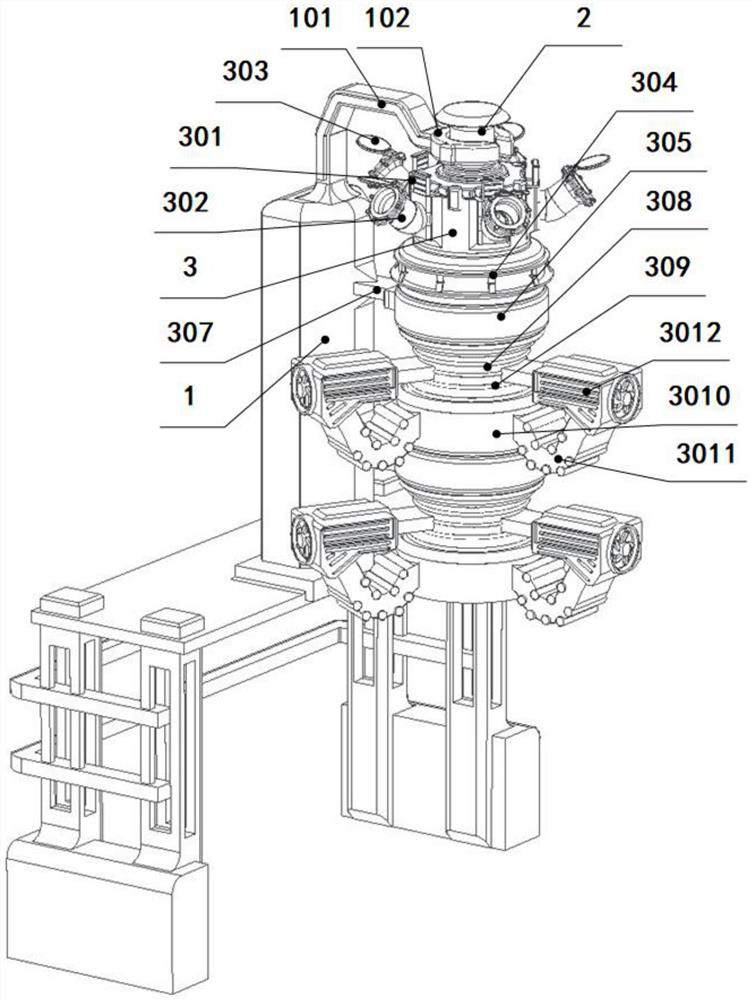

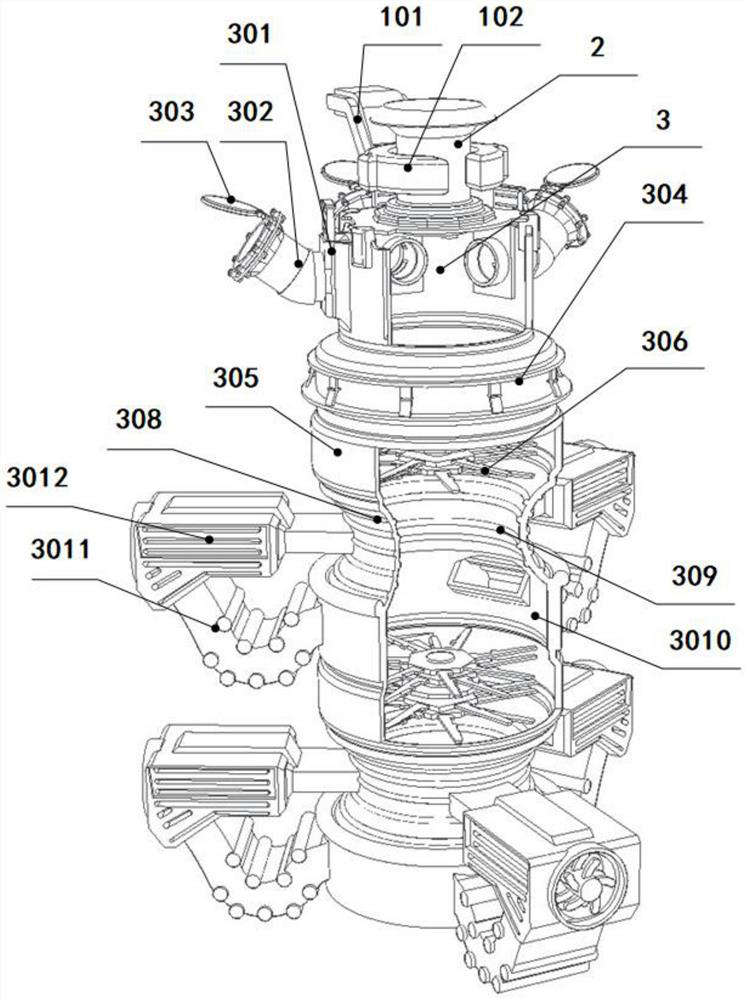

[0068] see Figure 1-20 , Multi / single crystal manganese oxide synthesis equipment for infrared detection and magnetic sensing, including colloidal system, transfer system, polycrystalline system, spin coating system, pulling system, sintering system;

[0069] The colloid system includes a mixing chamber 3, a transition collar 304, two crushing mechanisms, and a sol-gel reaction mechanism; the lower end of the mixing chamber 3 is connected to two crushing mechanisms through the transition collar 304, and the side walls of the mixing chamber 3 are connected to There are several feeding tubes 302, one end of the feeding tube 302 is provided with a sealed flip cover 303, the top of the mixing chamber 3 is provided with a rotating shaft 2, and the outer wall of the rotating shaft 2 is provided with a magnetic rotating ring 102, and the sol-gel reaction mechanism is located in the crushing mechanism Bottom: a lifting baffle 301 is provided at the connection between the feeding pipe...

Embodiment 2

[0096] The method for manufacturing polycrystalline or single crystal manganese oxide by the above synthesis equipment, specifically comprises the following steps:

[0097] (1) In the colloidal system, the colloids are uniformly synthesized by the sol-gel process;

[0098] (2) transport the colloid to the polycrystalline system through the transfer system to prepare the round block polycrystalline ceramic pre-material;

[0099] (3) The colloid is transported to the spin coating system by the transfer system to prepare a uniform precursor colloid film layer for spin coating;

[0100] (4) Transport the colloid to the lifting system through the transfer system to prepare the shaped precursor colloid film layer;

[0101] (5) The preliminary materials obtained in steps (2), (3) and (4) are respectively fired into final materials through a sintering system, and polycrystalline or single crystal manganese oxides can be prepared respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com