Medical metal material with modified film with photo-thermal characteristic on surface as well as preparation method and application of medical metal material

A metal material and modification technology, applied in metal material coating process, pharmaceutical formulation, medical science and other directions, can solve the problems of easy oxidation of non-precious metal nano-metal particles, reduction of nano-nickel cost, and inability to maintain photothermal effect for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A nickel-titanium (atomic ratio 1:1, purity 99.99%) alloy disc with a diameter of 10 mm and a thickness of 1 mm was cleaned with alcohol, deionized water and ultrasonic waves in sequence, each time for 15 min. Using a solution containing 3mM nickel chloride, 1mM titanium chloride, and 6.5g / L urea (108mM) as the hydrothermal medium, the sample was hydrothermally treated under airtight conditions. The hydrothermal temperature was 120°C for 24h. The filling degree of the hydrothermal kettle is 35%. After the hydrothermal treatment, wash with a large amount of deionized water until the pH of the cleaning solution drops to 7. After the sample is dried, it is placed in a mixed atmosphere of argon / hydrogen for heat treatment, the flow rate of argon gas is 20 sccm, the flow rate of hydrogen gas is 5 sccm, the heat treatment temperature is 450°C, and the heat treatment time is 1h.

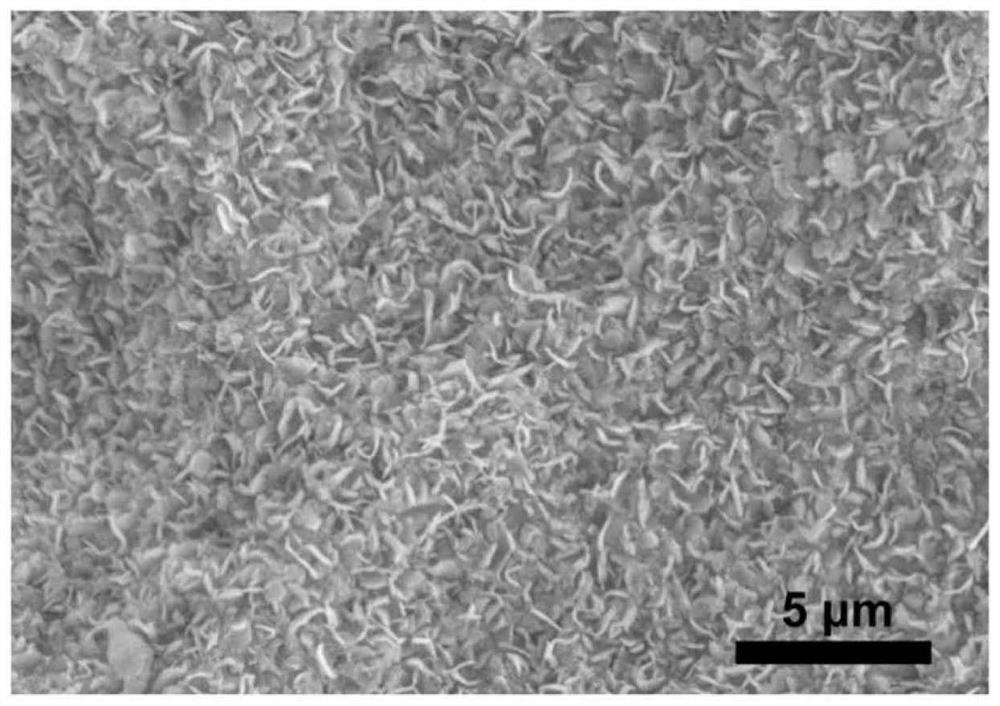

[0040] figure 1 It is a scanning electron microscope picture of the surface morphology of the ...

Embodiment 2

[0043] A nickel-titanium alloy disc with a diameter of 10mm and a thickness of 1mm (the atomic ratio of nickel to titanium is 1:1, and the purity is 99.99%) is cleaned with alcohol, deionized water, and ultrasonic in sequence, each time for 15 minutes. The sample was hydrothermally treated with a solution containing 3mM nickel chloride, 1mM titanium chloride, and 6.5g / L urea (108mM) as the hydrothermal medium. The hydrothermal temperature was 120°C for 24h. The filling degree of the hydrothermal kettle is 35%. After the hydrothermal treatment, wash with a large amount of deionized water until the pH of the cleaning solution drops to 7. After the sample was dried, it was placed in argon for heat treatment, the argon flow rate was 20 sccm, the heat treatment temperature was 450° C., and the heat treatment time was 1 h.

Embodiment 3

[0045] A nickel-titanium alloy disc with a diameter of 10mm and a thickness of 1mm (the atomic ratio of nickel to titanium is 1:1, and the purity is 99.99%) is cleaned with alcohol, deionized water, and ultrasonic in sequence, each time for 15 minutes. The sample was hydrothermally treated with a solution containing 6mM nickel chloride, 4mM titanium chloride, and 6.5g / L urea (108Mm) as the hydrothermal medium. The hydrothermal temperature was 120°C for 24h. The filling degree of the hydrothermal kettle is 35%. After the hydrothermal treatment, wash with a large amount of deionized water until the pH of the cleaning solution drops to 7. After the sample is dried, it is placed in a mixed atmosphere of argon / hydrogen for heat treatment, the flow rate of argon gas is 20 sccm, the flow rate of hydrogen gas is 5 sccm, the heat treatment temperature is 450°C, and the heat treatment time is 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com