Method for analyzing content of cyclopentane and extraction agent by gas chromatography

A gas chromatographic analysis and extractant technology, applied in the field of gas chromatographic analysis of cyclopentane and extractant content, can solve the problems of large gap in response factor and inaccurate measurement, and achieve low detection limit, good precision and high recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

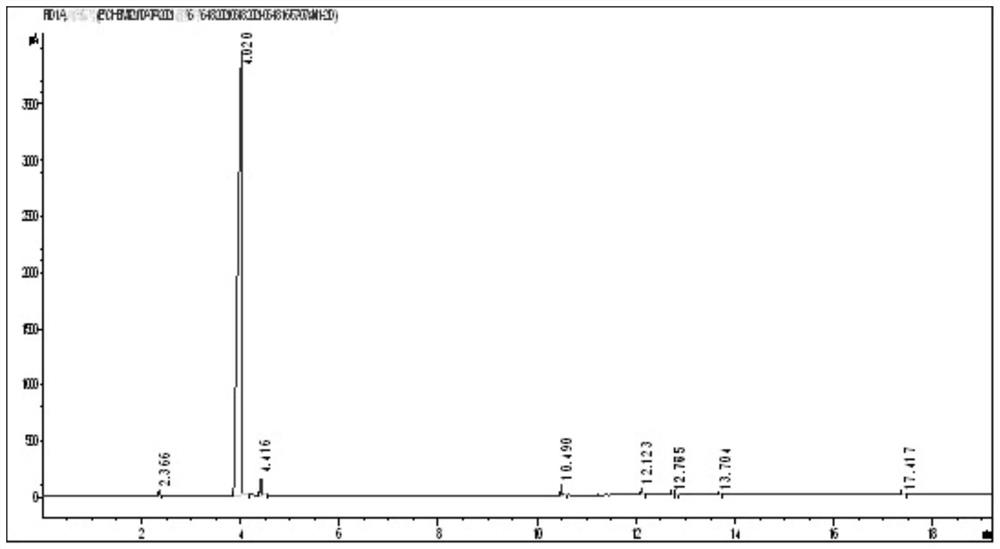

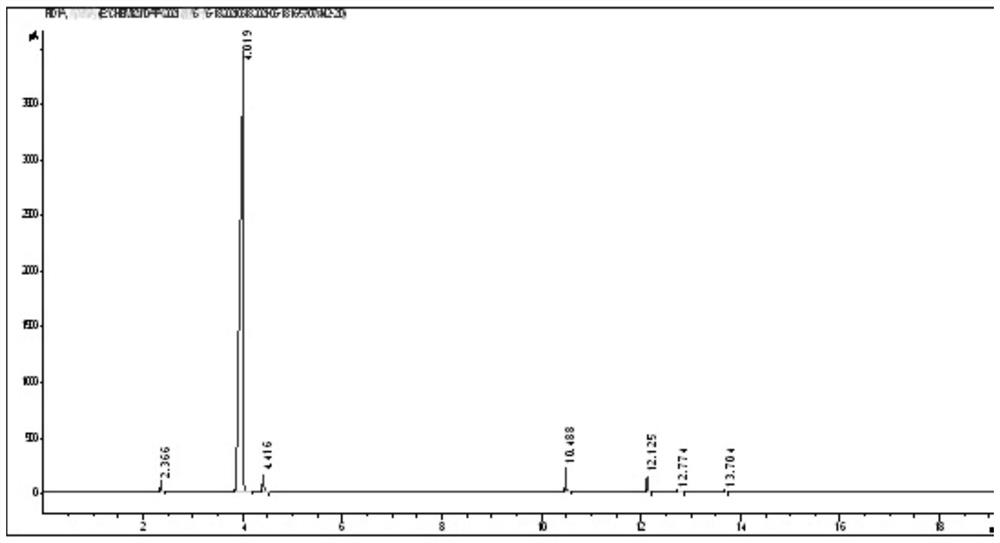

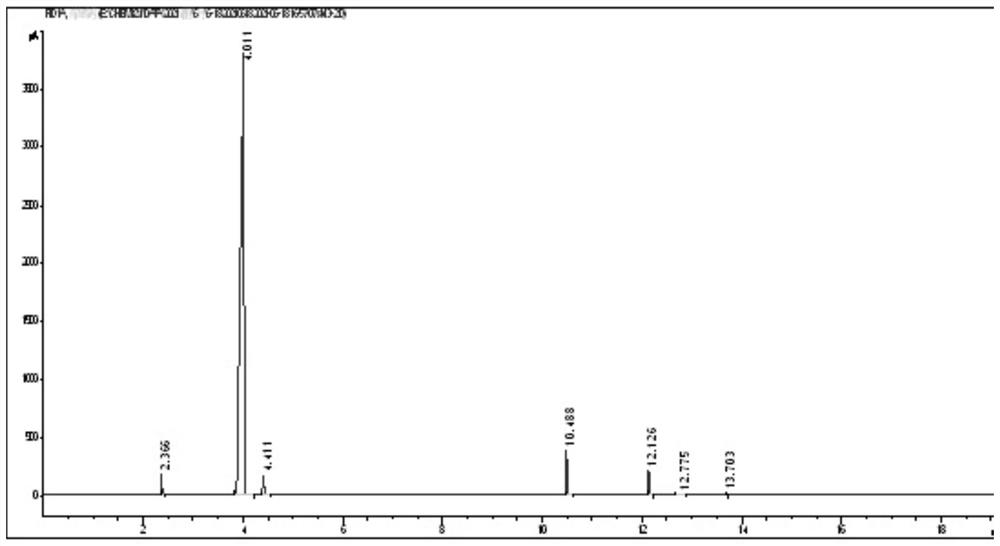

Image

Examples

Embodiment 1

[0046] 1.1 Experimental instruments and reagents:

[0047] (1) Gas chromatography: 7890B, Agilent, equipped with hydrogen flame ionization detector, equipped with G4513A autosampler; capillary column: HP-INNOWax (30m×0.25mm×0.25μm), 40-260°C, Agilent ;

[0048](2) Reagents: cyclopentane (mass fraction 98.08%), methanol, N,N-dimethylformamide, ethylene glycol, isopropanol, analytically pure;

[0049] 1.2 Steps for setting gas chromatograph detection conditions, gas chromatograph detection conditions include the following parameters:

[0050] a) The instrument used is an Agilent 7890B gas chromatograph equipped with a hydrogen flame ionization detector, and the chromatographic column is Agilent HP-INNOWax (30m×0.25mm×0.25μm), 40-260°C;

[0051] b) Heating program: keep at 45°C for 6 minutes, raise the temperature to 250°C at a rate of 25°C / min, and hold for 5 minutes;

[0052] c) Carrier gas: nitrogen, with a purity greater than 99.999%;

[0053] d) Inlet temperature: 250°C;...

Embodiment 2

[0070] The instrument used, the detection conditions are set, the standard solution configured, and the standard curve drawn are all the same as in Example 1;

[0071] Determination and calculation of samples

[0072] Sample preparation steps: accurately weigh 0.9542 g of rich solvent sample (solvent at the bottom of extractive distillation tower) and 80.5 mg of internal standard - isopropanol in a 10ml volumetric flask, and then accurately weigh poor solvent sample (extraction solvent Recover tower bottom solvent) 0.7339g and internal standard-isopropanol 82.2mg, dilute with methanol to the mark, mix evenly to obtain sample solution, transfer to chromatographic bottle for gas phase detection. Record the ratio of the peak area of each component in the sample to the internal standard, and calculate the contents of cyclopentane, N,N-dimethylformamide, and ethylene glycol in the sample according to the standard curve regression equation in 1.4. The contents of cyclopentane, N,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Injection volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com