Dry-method powder preparation process of foamed ceramic

A technology for foaming ceramics and dry milling, applied in the field of ceramic materials, can solve the problems of large dust, low efficiency, uneven dispersion of foaming agents, etc., and achieve the effects of concentrated pore size distribution, low production energy consumption, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

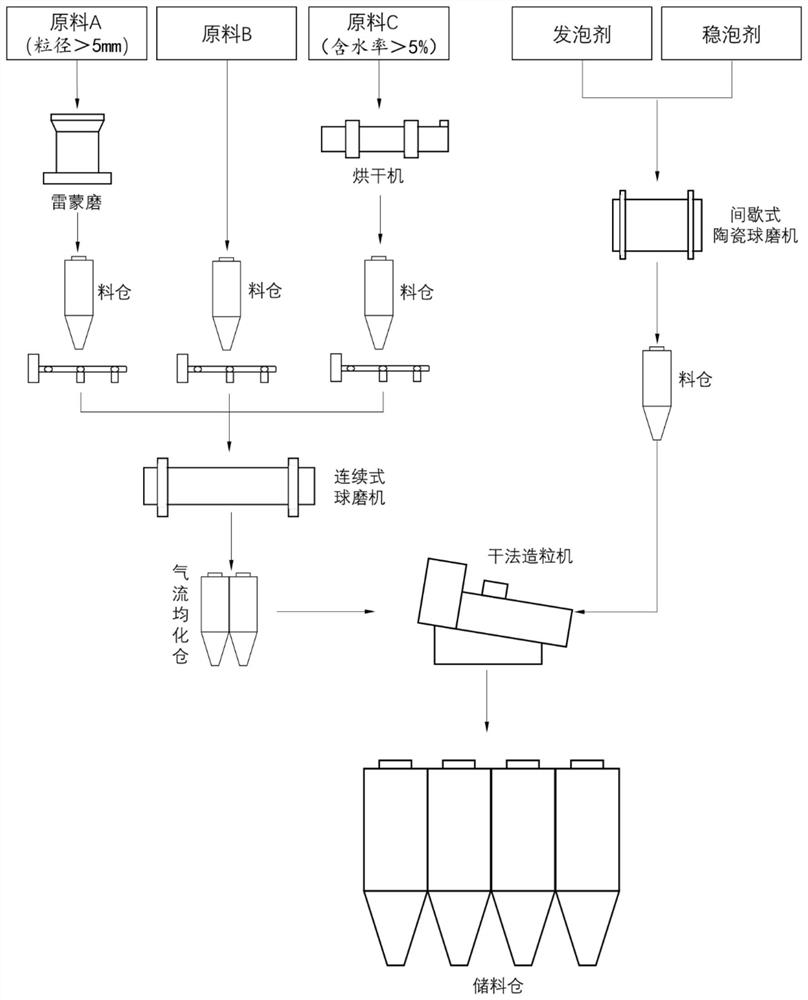

Method used

Image

Examples

Embodiment 1

[0036] (1) Select bauxite tailings, fly ash and feldspar as the main raw materials, use a dryer to dry the bauxite tailings with a moisture content of 10% to a moisture content of <1%, and use a Raymond mill to dry the bauxite tailings from the original state The feldspar is ground until all pass through a 100-mesh standard sieve (particle size <0.15mm), and the three processed raw materials are stored in the silo respectively.

[0037] (2) Using a belt scale, according to the ratio of bauxite tailings: fly ash: feldspar = 30%: 25%: 40%, weigh each raw material, and lay them on the belt conveyor in turn, and send them into the continuous In the dry-type ball mill, after about 40 minutes of grinding in the mill, the particle size of the milled powder reaches 45 μm and 0.5% of the sieve, and is transported to the airflow homogenization bin for storage.

[0038] (3) Lightly burned magnesia is used as a foam stabilizer, and SiC micropowder is used as a foaming agent. Two kinds of ...

Embodiment 2

[0042] (1) Choose polished brick slag and coal gangue as the main raw materials, use a dryer to dry the polished brick slag with a moisture content of 9.6% to a moisture content of <1%, and use a Raymond mill to grind the coal gangue until it passes through 100 mesh Standard sieve (particle size <0.15mm), and the processed two raw materials are stored in the raw material warehouse respectively.

[0043](2) Adopt a belt scale, according to polished brick slag: coal gangue = 70%: 24%, weigh each raw material, and spread it on the belt conveyor in turn, and send it into the continuous dry ball mill at the same time, and grind it in the mill for about 30min Finally, the particle size of the milled powder meets 0.8% of the 45μm sieve, and is transported to the airflow homogenization bin for storage.

[0044] (3) Light-burned magnesia is used as a foam stabilizer, and SiC micropowder is used as a foaming agent. Take two kinds of admixtures according to the ratio of foaming agent:foa...

Embodiment 3

[0048] (1) Select coal-fired slag, copper tailings, and chromium slag as the main raw materials, use a dryer to dry the copper tailings with a moisture content of 6.5% to a moisture content of <1%, and use a Raymond mill to dry the coal-fired slag, chromium The slag is ground separately until all of them pass through a 100-mesh standard sieve (particle size <0.15mm), and the three processed raw materials are stored in the raw material warehouse respectively.

[0049] (2) Adopt a belt scale, according to coal-fired slag: copper tailings: chrome slag=35%: 45%: 16%, take each raw material, and spread on the belt conveyor successively, send into continuous dry process ball mill simultaneously After grinding for about 45 minutes in the internal and internal mills, the particle size of the milled powder meets 45 μm sieve with 0.5% remaining, and is transported to the airflow homogenization bin for storage.

[0050] (3) Light-burned magnesia is used as a foam stabilizer, and SiC micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com