Preparation method of ruthenium-doped lithium cobalt oxide positive electrode material with core-shell structure

A technology of structural lithium cobaltate and positive electrode materials, applied in the direction of positive electrodes, structural parts, chemical instruments and methods, etc., can solve the problems of poor rate performance, unfavorable lithium ion migration and diffusion, etc., and achieve improved rate performance and fast ion transmission Effects of mild nature and conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

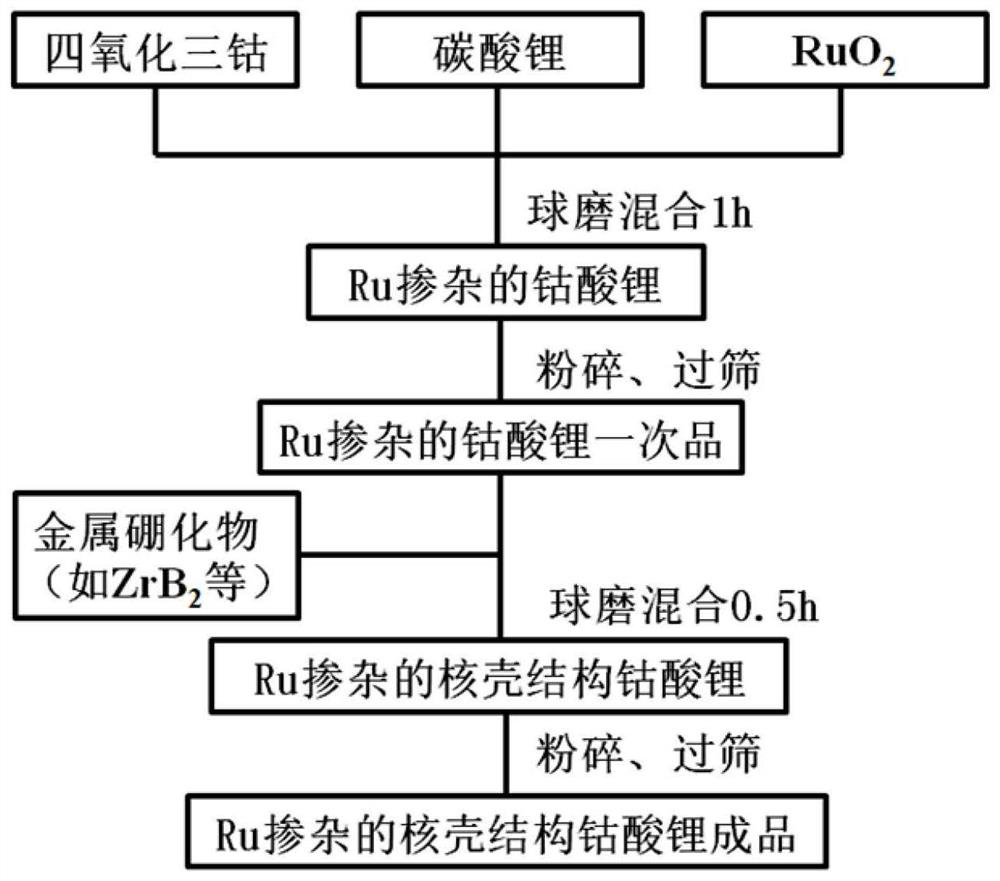

[0038] Preparation of Ru-LCO cathode material:

[0039] Weigh 140g of cobalt tetroxide, 66.65g of lithium carbonate and 0.227g of ruthenium dioxide and place them in a ball milling tank for mixing. The ball milling speed is 300rad / min, and the ball milling time is 1h. Transfer the sagger to a muffle furnace, heat up to 1020°C at a rate of 7°C / min for calcination for 10 hours, and continuously feed air as an oxygen source during the sintering process; take it out after naturally cooling to room temperature; place the obtained sample in In a small universal pulverizer, grind for 20 seconds, pour the pulverized sample into a 325-mesh sieve for sieving treatment, collect the sieved sample, and obtain Ru-LCO;

[0040] Preparation of Ru-LCO / M cathode material:

[0041] Weigh 100g of Ru-LCO and 0.189g of ZrB 2 Put it in a ball mill jar for mixing, the ball mill speed is 300rad / min, and the ball mill is 0.5h. The blended powder is evenly and evenly distributed in the sagger, and the...

Embodiment 2

[0043] Preparation of Ru-LCO cathode material:

[0044] a. First mix tricobalt tetroxide, lithium carbonate and ruthenium dioxide, the mass fraction of ruthenium dioxide is 0.1%, put the mixed raw materials into a ball mill for mixing ball milling, the speed of the ball mill is 300rad / min, and the ball milling time is 1h; then the mixture after ball milling Transfer to a muffle furnace for calcination, set the temperature rise rate of the muffle furnace to 5°C / min, the calcination temperature is 1000°C, and the calcination time is 8h. Air is continuously fed in during the calcination process as an oxygen source. After the calcination, the sample is cooled to room temperature and taken out. .

[0045] b. After the sample obtained in step a is coarsely pulverized with a mortar, pour it into a universal pulverizer for pulverization. The speed of the universal pulverizer is 25000r / min, and the pulverization time is 15s. Pour the pulverized sample into a 325-mesh sieve for sieving...

Embodiment 3

[0050] Preparation of Ru-LCO cathode material:

[0051] a. first mix tricobalt tetroxide, lithium carbonate and ruthenium dioxide, the mass fraction of ruthenium dioxide is 0.2%, put the mixed raw materials into a ball mill for mixed ball milling, the ball mill speed is 300rad / min, and the ball milling time is 1.5h; then the ball milled The mixture was transferred to a muffle furnace for calcination. The temperature rise rate of the muffle furnace was set at 10°C / min, the calcination temperature was 1050°C, and the calcination time was 10h. During the calcination process, air was continuously introduced as an oxygen source. After the calcination, the sample was cooled to room temperature. take out.

[0052] b. Roughly pulverize the sample obtained in step a with a mortar, pour it into a universal pulverizer for pulverization, the speed of the universal pulverizer is 25000r / min, and the pulverization time is 30s. Pour the pulverized sample into a 325-mesh sieve for sieving tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com