Method for comprehensively separating and recycling materials in retired batteries

A technology for separation and recycling of batteries, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as human health hazards, poisonous lithium bromide solution, failure to separate positive electrode materials from positive electrode current collectors, etc., to reduce pollution and energy consumption, the method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

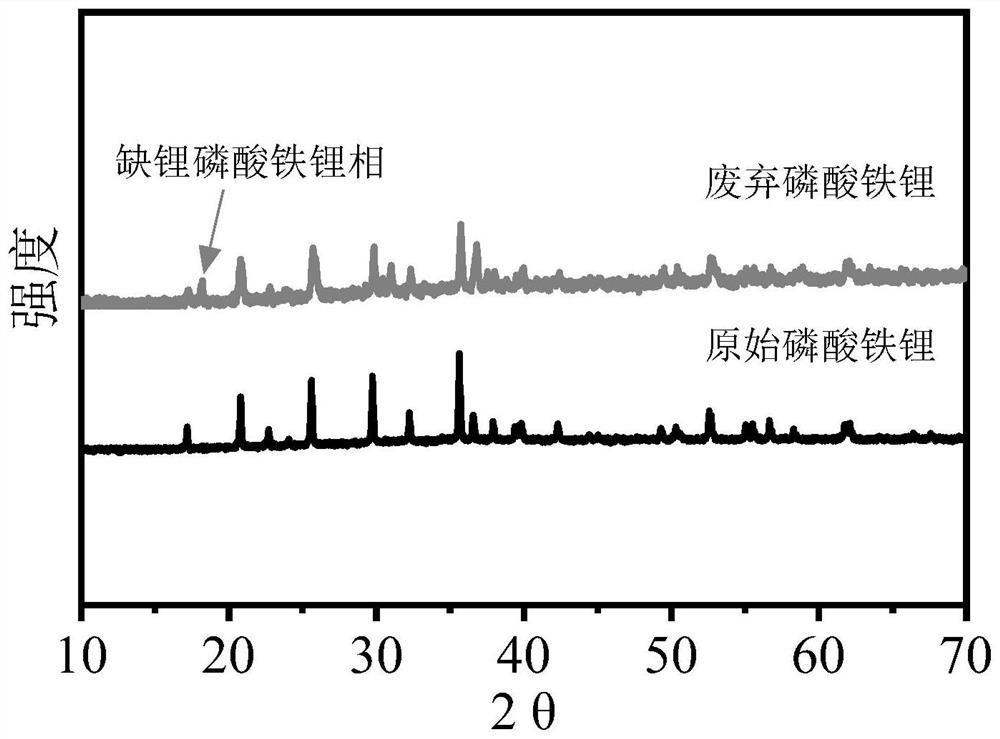

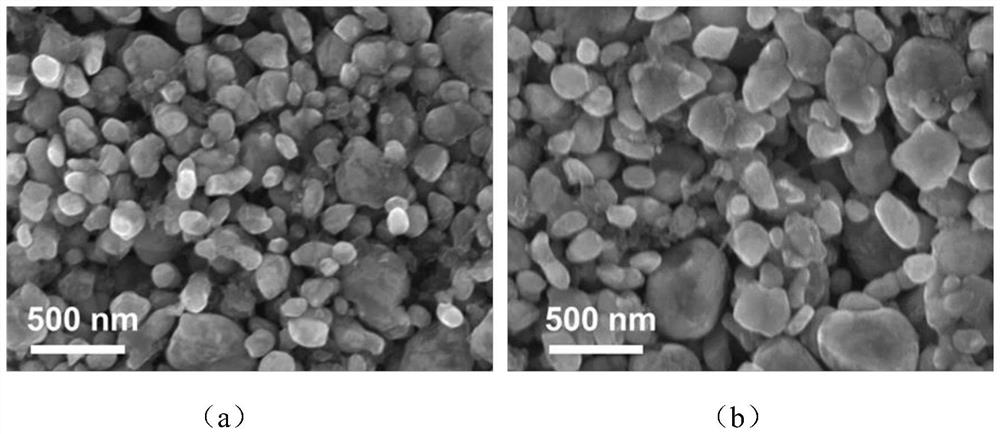

Embodiment 1

[0042] Disassemble the waste lithium iron phosphate battery (the content of the positive electrode binder PVDF is 5%, and the negative electrode binder PVA is 5%), take out the positive electrode sheet and the negative electrode sheet wrapped by the inner diaphragm, and pull out the diaphragm to obtain the positive electrode sheet Mix with the negative pole piece, soak it in 20°C water (water volume: pole piece volume = 15:1) for 0.5h with mechanical stirring at a speed of 300 rpm, then use a mesh with a pore size of 0.1cm for the mixed liquid Sieve screening, dry the sieved oversize (positive electrode material, copper foil, aluminum foil) and undersize (graphite, water), and carry out secondary screening on the obtained oversize, with a sieve aperture of 2cm, The undersize (positive electrode material) and oversize (copper foil, aluminum foil) are obtained, and then the mixture of copper foil and aluminum foil is subjected to eddy current separation to obtain copper and alumi...

Embodiment 2

[0050] Disassemble the waste nickel-cobalt-manganese ternary battery (the positive electrode binder PVDF content is 3%, the negative electrode binder CMC is 5%), take out the positive electrode sheet and the negative electrode sheet wrapped by the inner diaphragm, and pull out the diaphragm to obtain the positive electrode For the mixing of pole piece and negative pole piece, soak it in 30°C water (water volume: pole piece volume = 15:1) and mechanically stir for 1h at a speed of 700 rpm, then use a mesh with a pore size of 0.1cm for the mixed liquid Sieve screening, dry the sieved oversize (positive electrode material, copper foil, aluminum foil) and undersize (graphite, water), and carry out secondary screening on the obtained oversize, with a sieve aperture of 2cm, The undersize (positive electrode material) and oversize (copper foil, aluminum foil) are obtained, and then the mixture of copper foil and aluminum foil is subjected to eddy current separation to obtain copper an...

Embodiment 3

[0053] Disassemble the waste lithium iron phosphate (positive electrode binder content is 6%, negative electrode binder SBR is 5%) batteries, take out the positive electrode sheet and negative electrode sheet wrapped by the inner diaphragm, and pull out the separator to obtain the positive electrode sheet and the negative electrode sheet. For the mixing of the negative pole piece, soak it in 80°C water (water volume: pole piece volume = 15:1) and mechanically stir for 1 hour at a speed of 500 rpm, then use a mesh screen with a pore size of 0.1cm for the mixed liquid Screening, drying the screened oversize (positive electrode material, copper foil, aluminum foil) and undersize (graphite, water), and secondary screening of the obtained oversize, with a sieve aperture of 2 cm, to obtain The undersize (positive electrode material) and oversize (copper foil, aluminum foil), and then the mixture of copper foil and aluminum foil is crushed and sorted to obtain copper and aluminum with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com