Preparation method of surface-hybridized high-strength silicon dioxide microspheres

A silicon dioxide, high-strength technology, applied in the directions of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of high mechanical strength of silica gel, separation and interference of alkaline substances, limited application scope, etc., and achieve excellent physical and chemical stability, great practical value and economic value, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

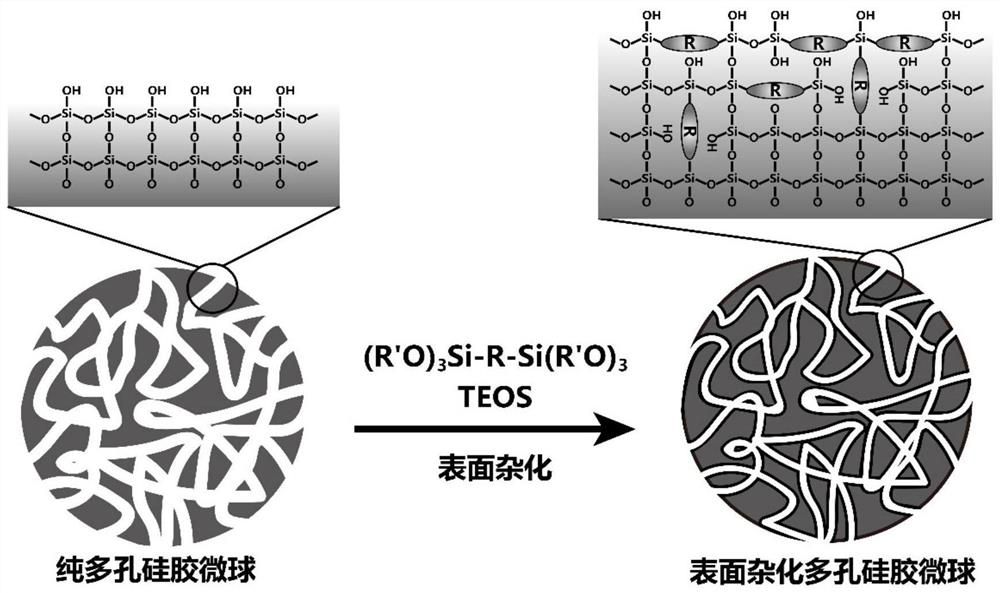

[0019] Example 1: Preparation of ethyl-bridged surface hybrid silica microspheres

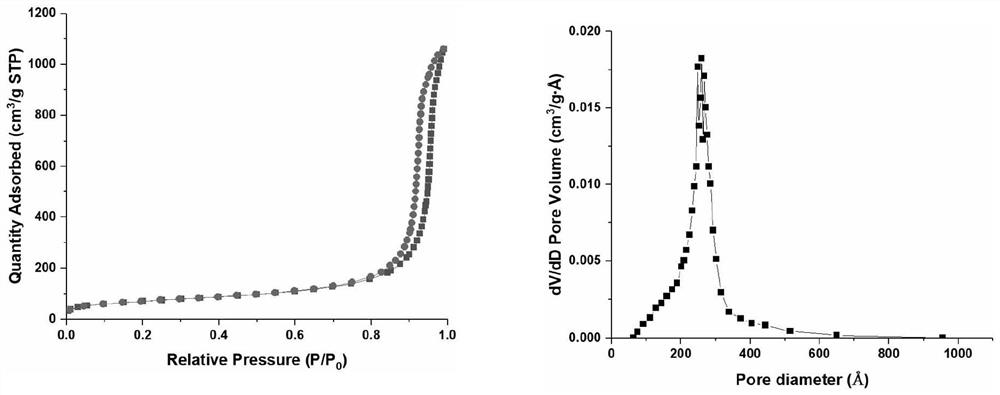

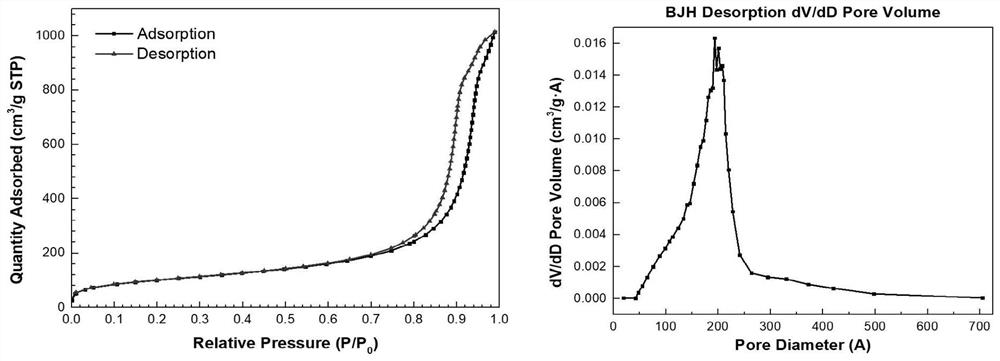

[0020] Using 1,2-bis(triethoxysilane)ethane (BTMSE) and tetraethyl orthosilicate (TEOS), the surface of porous silica was covered by hybridization. The specific method is as follows: Weigh 100g of particles with a particle size of 7 μm and a pore size of The high-purity silica microspheres were calcined at 600°C for 10h, then dried at 120°C for 24h, put into a 1000mL three-necked bottle, placed in an oil bath, connected to a condenser tube containing a desiccant and a mechanical stirrer, and added 450mL to dry Toluene, heated to about 120°C to reflux the toluene, then added 16.4g imidazole, stirred for 10min, then added dropwise the mixed solution of 10g BTMSE, 15g TEOS and 150mL toluene with the dropping funnel, the dropwise addition was completed within 15min, and continued to reflux for 12h, then Stir and cool to room temperature, remove the solvent by filtering with a sand core funnel, th...

Embodiment 2

[0023] Similar to Example 1, the difference is that 1,4-bis(triethoxysilyl)benzene (BTEB) and ethyl silicate (TEOS) are used to hybridize the surface of high-purity porous silica gel, and the calcination temperature is 800°C , lasted 12h, and baked at 200°C for 8h before mixing with toluene to fully dry the microspheres. The basic catalyst used in the hybridization reaction is pyridine, and the dosage is 5% of the mass concentration of the system.

Embodiment 3

[0025] Similar to Example 1, the difference lies in the pore size of the high-purity inorganic silica microspheres , the calcination temperature was 400°C for 2h, and baked at 100°C for 15h before mixing with toluene. The basic catalyst used in the hybridization reaction is triethylamine, and the dosage is 10% of the mass concentration of the system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com