Method for preparing fucoidan by biological coupling method

A technology of fucoidan and coupling method, applied in the field of polysaccharide extraction, can solve the problems of destruction of active components, high production cost, low extraction efficiency of fucoidan, etc., achieves rapid reaction, large processing capacity, and is conducive to large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

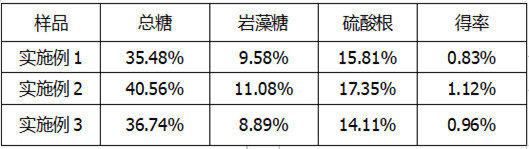

Examples

Embodiment 1

[0024] (1) Raw material pretreatment: Wash and dry the kelp with tap water, cut the dried kelp into small pieces with a knife, and crush it to 80 meshes;

[0025] (2) Biological enzymatic hydrolysis: Add 1:30 water to the kelp powder obtained in step (1), adjust the pH to 4.8 with hydrochloric acid, add 1% acid cellulase, 0.5% acid pectinase, and stir at 50°C 2h; adjust the pH of the enzymolysis solution to 8.0, add 0.2% alkaline pectinase, and carry out the enzymolysis reaction at 60°C for another 1.5 hours;

[0026] (3) Biological fermentation: Sterilize the enzymatic hydrolyzate obtained in step (2), add Aspergillus niger and Stenotrophomonas maltophilia for mixed fermentation, the inoculum ratio is 1:1, and the total inoculum amount: 10%. The fermentation condition is 30°C, 200r / min fermentation for 72h;

[0027] (4) Calcium precipitation: After the fermentation, the fermentation product was centrifuged, and 30% calcium chloride was added to filter to remove the precipita...

Embodiment 2

[0029] (1) Raw material pretreatment: Wash and dry the kelp with tap water, cut the dried kelp into small pieces with a knife, and crush it to 80 meshes;

[0030] (2) Biological enzymatic hydrolysis: Add 1:40 water to the kelp powder obtained in step (1), adjust the pH to 5.0 with hydrochloric acid, add 5% acid cellulase, 1% acid pectinase), at 50°C Stir for 2 hours; adjust the pH of the enzymolysis solution to 9.0, add 0.2% alkaline pectinase, and carry out the enzymolysis reaction at 60°C for 1.5 hours;

[0031] (3) Biological fermentation: Sterilize the enzymatic hydrolyzate obtained in step (2), insert yeast and lactic acid bacteria for mixed fermentation, the inoculum ratio is 1:2, and the total inoculation amount: 9%. The fermentation condition is 30°C, 200r / min fermentation for 48h;

[0032] (4) Calcium precipitation: After the fermentation is over, centrifuge the fermentation product, add 35% calcium chloride to filter to remove the precipitate, and collect the supern...

Embodiment 3

[0035] (1) Raw material pretreatment: Wash and dry the kelp with tap water, cut the dried kelp into small pieces with a knife, and crush it to 100 mesh;

[0036] (2) Biological enzymatic hydrolysis: Add 1:50 water to the kelp powder obtained in step (1), adjust the pH to 5.0 with hydrochloric acid, add 3% acid cellulase and 1% acid pectinase, and stir at 50°C 2h; adjust the pH of the enzymolysis solution to 8.0, add 0.5% alkaline pectinase, and carry out the enzymolysis reaction at 60°C for another 1.5 hours;

[0037] (3) Biological fermentation: Sterilize the enzymatic hydrolyzate obtained in step (2), insert Bacillus subtilis and Stenotrophomonas maltophilia for mixed fermentation, the inoculum ratio is 1:1, the total inoculation amount: 5% . The fermentation condition is 30°C, 200r / min fermentation for 48h;

[0038] (4) Calcium precipitation: After the fermentation, the fermentation product was centrifuged, and 40% calcium chloride was added to filter to remove the precip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com