Cow vamp leather pretreatment method based on season change and application thereof

A shoe upper leather and pretreatment technology, which is applied in the field of tanning, can solve the problems of blocking the collagen fiber channel of the leather, and achieve the effects of reducing stress, reducing usage, and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

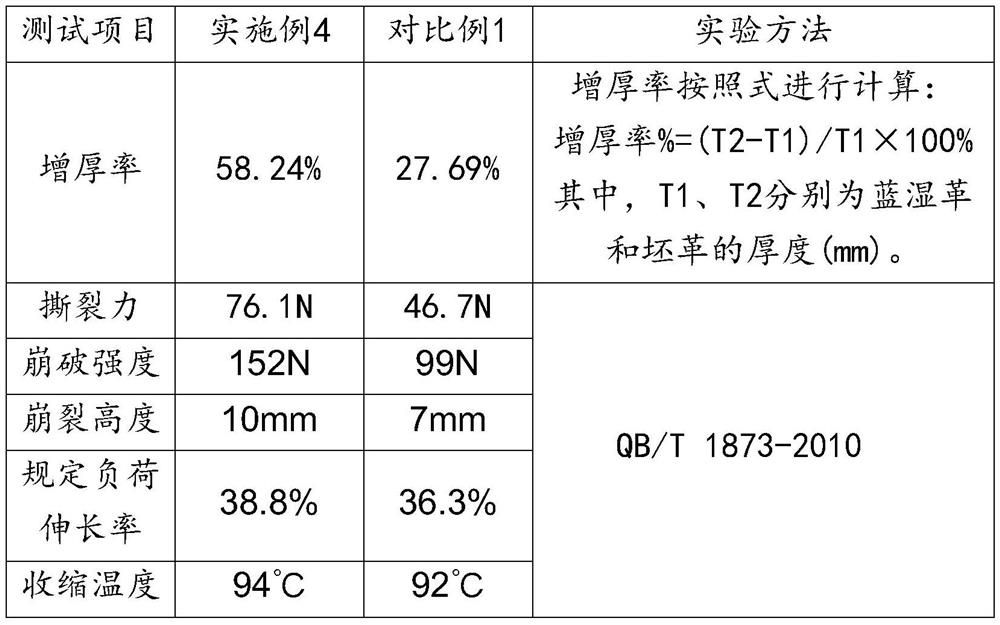

Examples

Embodiment 1

[0030] A kind of cow shoe upper leather pretreatment method based on seasonal change, comprises the steps:

[0031] (1) Preparation of moisture rehydrating agent: mix 50 parts of maleic anhydride, 40 parts of stearic acid, 55 parts of trimethylolpropane, 12 parts of polyethylene glycol, 8 parts of xylene, and 1 part of lithium hydroxide, Under the protection of nitrogen, raise the temperature to 150°C, stir for 1h, then raise the temperature to 190°C, stir for 1h, then distill off xylene under reduced pressure, cool down to 60°C, add 20 parts of ethylene glycol monobutyl ether, then cool down to 20°C, add 120 parts of distilled water, stirred for 0.5h, to obtain a moisture rehydrating agent;

[0032] (2) Preparation of composite moisture rehydrating agent: at 30°C, take 100 parts of water, add 30 parts of oxalic acid, 10 parts of sodium edetate, and 10 parts of boric acid, mix well and lower the temperature to 18°C, add 17 parts of egg white Filler (PC, Sichuan Desaier), 10 p...

Embodiment 2

[0038] A kind of cow shoe upper leather pretreatment method based on seasonal change, comprises the steps:

[0039] (1) Preparation of moisture rehydrating agent: 65 parts of maleic anhydride, 20 parts of stearic acid, 30 parts of palmitic acid, 62 parts of trimethylolpropane, 13 parts of polyethylene glycol, 9 parts of xylene, 2 parts of hydrogen Mix lithium oxide evenly, raise the temperature to 155°C under the protection of nitrogen, stir for 1h, then raise the temperature to 185°C, stir for 1h, then distill off xylene under reduced pressure, cool down to 75°C, add 20 parts of ethylene glycol monobutyl ether, and then Cool down to 20°C, add 145 parts of distilled water, and stir for 0.5h to obtain a moisture rehydrating agent;

[0040] (2) Preparation of composite moisture rehydrating agent: at 32°C, take 100 parts of water, add 43 parts of oxalic acid, 7 parts of sodium edetate, and 5 parts of boric acid, mix well and lower the temperature to 16°C, add 15 parts of egg whit...

Embodiment 3

[0046] A kind of cow shoe upper leather pretreatment method based on seasonal change, comprises the steps:

[0047] (1) Preparation of moisture rehydrating agent: mix 75 parts of maleic anhydride, 55 parts of palmitic acid, 68 parts of trimethylolpropane, 15 parts of polyethylene glycol, 8 parts of xylene, and 3 parts of lithium hydroxide, Under the protection of nitrogen, raise the temperature to 158°C, stir for 1h, then raise the temperature to 195°C, stir for 1h, then remove xylene by distillation under reduced pressure, cool down to 75°C, add 20 parts of ethylene glycol monobutyl ether, then cool down to 22°C, add 105 parts of distilled water, stirred for 0.5h, to obtain a moisture rehydrating agent;

[0048] (2) Preparation of composite moisture rehydrating agent: at 35°C, take 100 parts of water, add 40 parts of oxalic acid, 8 parts of sodium edetate, and 7 parts of boric acid, mix well and lower the temperature to 20°C, add 20 parts of egg white Filler (340, Beijing Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com