Anti-cavitation corrosion-resistant metal-ceramic matrix composite material and preparation method thereof

A composite material and ceramic material technology, applied in the field of metal-ceramic composite material preparation, can solve problems such as uncoated corrosion resistance research, improve cavitation resistance and corrosion resistance, prolong service time, and reduce processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

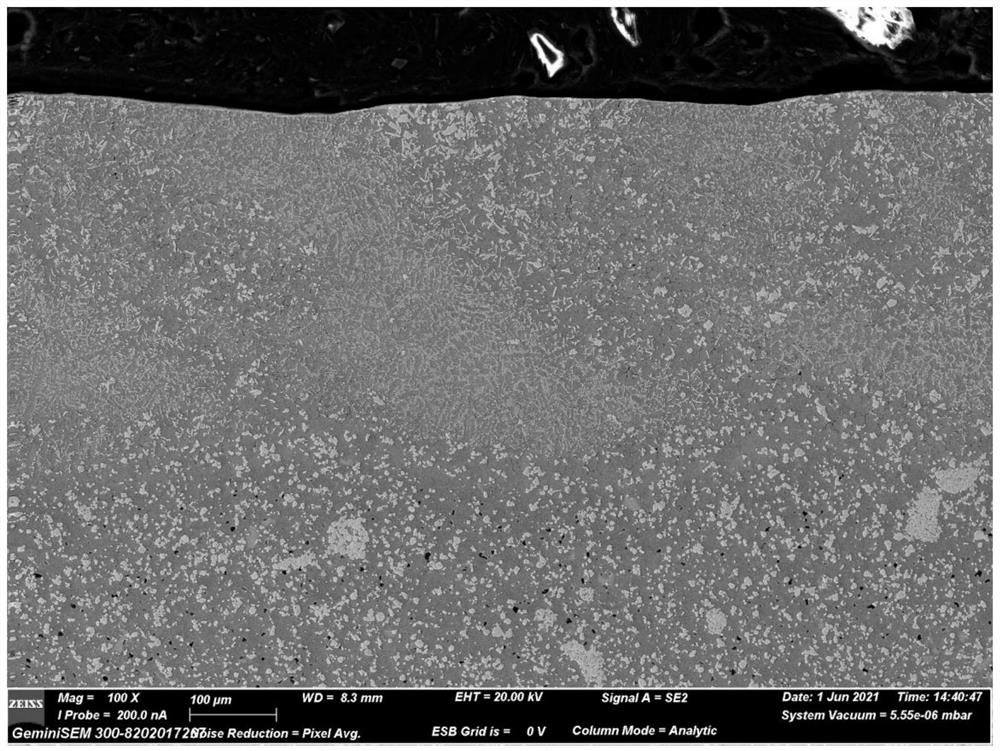

[0034] In this embodiment, the metal material is nickel powder, the ceramic material is tungsten carbide powder, and the rare earth material is cerium oxide powder. The steps of preparing the cavitation-resistant and corrosion-resistant metal-ceramic matrix composite material include:

[0035] (1) Mix nickel powder and tungsten carbide powder at a volume ratio of 70±5% and 30±5% (the required mass can be calculated by theoretical density), and then add 2±0.5% of the total mass of nickel powder and tungsten carbide powder Cerium oxide powder, mixed evenly, then poured into molds;

[0036] (2) Send the mold into a vacuum sintering furnace, fully sinter the powder under a pressure of 40 MPa and a temperature of 1200°C for 1 hour; then cool naturally, and take out the formed composite preform;

[0037](3) Clean the prefabricated part of step (2) with ethanol. After drying, use 60 mesh brown corundum sand to roughen its surface. The air pressure of sandblasting is 1MPa, and the san...

Embodiment 2

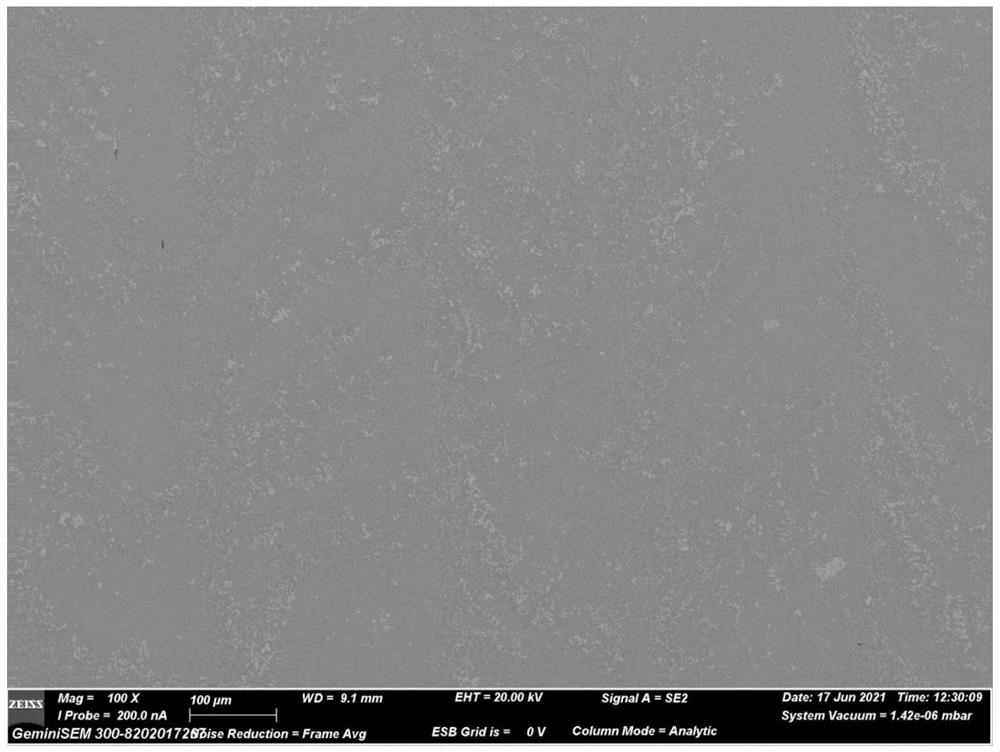

[0040] In this embodiment, the metal material is block nickel and flake chromium, the ceramic material is tungsten carbide powder, and the rare earth material is lanthanum oxide powder. The steps of preparing the cavitation-resistant and corrosion-resistant metal-ceramic matrix composite material include:

[0041] (1) Mix block nickel, flake chromium and tungsten carbide powder according to the volume ratio of 15±5%, 55±5%, 30±5%, and then add the total mass of block nickel, flake chromium and tungsten carbide powder 3±1% lanthanum oxide powder, mixed evenly, then poured into the crucible of the vacuum induction melting furnace for heating;

[0042] (2) When the temperature reaches 2400°C, keep it for 3 minutes, then pour the molten material in the crucible into the copper mold, and after it is completely cooled, take out the formed composite preform;

[0043] (3) Clean the prefabricated part of step (2) with ethanol. After drying, use 60 mesh brown corundum sand to roughen it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com