Aluminum-free deep-fried dough stick leavening agent and preparation method thereof

A technology of leavening agent and reactant for fried dough sticks, which is applied in the field of leavening agent for fried dough sticks, which can solve the problems affecting product use effect and health, and achieve the effects of improving taste, coagulation force and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the carrier reactant of the present embodiment is:

[0053] Step 1: Mix sodium alginate and deionized water according to the weight ratio of 1:5, then ultrasonically disperse for 10-20min, and the ultrasonic power is 100-200W to obtain sodium alginate solution;

[0054] Step 2: Mix the amino acid and organic selenium according to the weight ratio of 2:1, stir until fully, then add lactulose oligosaccharide with 10-20% of the total amount of amino acid, continue stirring until fully, and obtain the carrier agent;

[0055] Step 3: Then add a sodium alginate solution 2-3 times the total amount of the carrier agent, and continue stirring at a constant speed of 100-200r / min until the raw materials are sufficient to obtain a carrier reactant.

[0056] A kind of preparation method of aluminum-free deep-fried dough stick leavening agent of the present embodiment, comprises the following steps:

[0057] Step 1, adding low-moisture cornstarch, sodium bi...

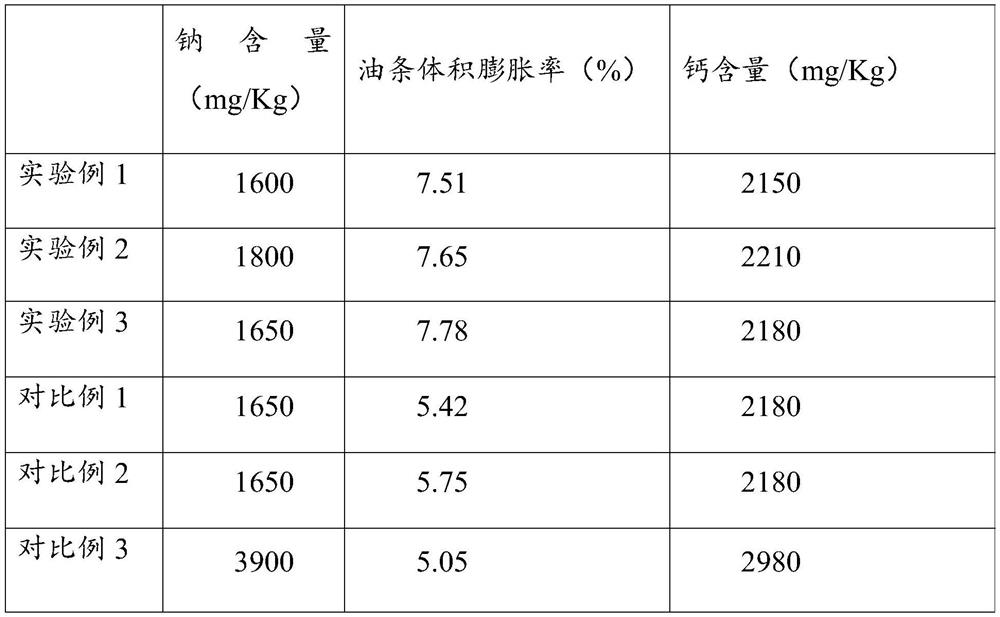

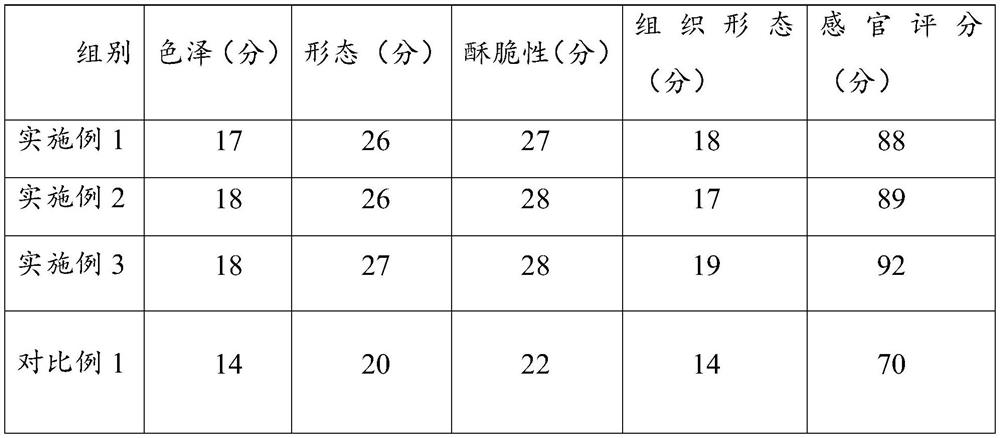

Embodiment 1

[0062] A kind of leavening agent for aluminum-free fried dough sticks of the present embodiment comprises the following raw materials in weight percent:

[0063] Sodium bicarbonate 30%, soybean protein powder modified calcium dihydrogen phosphate 5%, carrier reactant 3%, glucose oxidase 1%, and the balance is low-moisture cornstarch.

[0064] The modification method of the soybean protein powder modified calcium dihydrogen phosphate of the present embodiment is:

[0065] S1: Send soybean protein and calcium dihydrogen phosphate into the grinder for grinding according to the total ratio of 3:2, and grind to 200 mesh;

[0066] S2: Then send it into 1 times the chitosan solution for stirring treatment, stir until fully, and obtain the chitosan medium body;

[0067] S3: Then add modified vegetable oil with 1% of the total amount of chitosan medium, stir until fully, and obtain a modified body;

[0068] S4: Then add 1% of the total amount of modified catalyst body, react at 55° C...

Embodiment 2

[0082] A kind of leavening agent for aluminum-free fried dough sticks of the present embodiment comprises the following raw materials in weight percent:

[0083] Sodium bicarbonate 35%, soybean protein powder modified calcium dihydrogen phosphate 15%, carrier reactant 6%, glucose oxidase 3%, and the balance is low-moisture cornstarch.

[0084] The modification method of the soybean protein powder modified calcium dihydrogen phosphate of the present embodiment is:

[0085] S1: Send soybean protein and calcium dihydrogen phosphate into the grinder according to the total ratio of 3:2 for grinding, and grind to 400 mesh;

[0086] S2: Then send it into the chitosan solution of 3 times for stirring treatment, stir until fully, and obtain the chitosan medium body;

[0087] S3: Then add modified vegetable oil with 5% of the total amount of chitosan medium, stir until fully, and obtain a modified body;

[0088] S4: Then add 3% of the total modified catalyst body, react at 65° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com