Degradable pure magnesium or magnesium alloy oral biological barrier membrane and preparation method thereof

A bio-barrier and magnesium alloy technology, which can be used in manufacturing tools, drug delivery, pharmaceutical formulations, etc., can solve the problems of too fast degradation of magnesium alloy oral biofilm and insufficient bone tissue integration effect, and achieve the purpose of inhibiting epithelial cells or hoof tissue Proliferation, improve the uniformity of degradation, eliminate the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

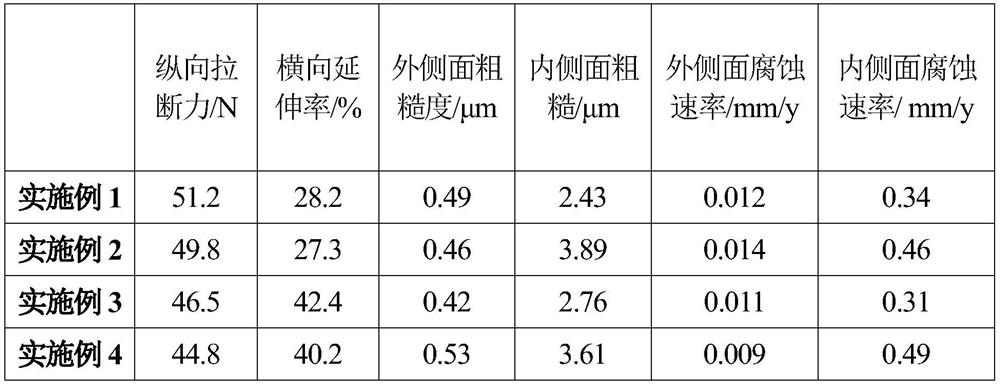

Examples

Embodiment 1

[0035] In this embodiment, the preparation method of the degradable magnesium alloy oral biological barrier film comprises the following steps:

[0036] Step 1. The magnesium alloy sheet containing 2% Zn and 0.5% Nd is rolled three times and vacuum annealed at 200° C. for 2 hours to obtain a magnesium alloy foil with a thickness of 200 μm.

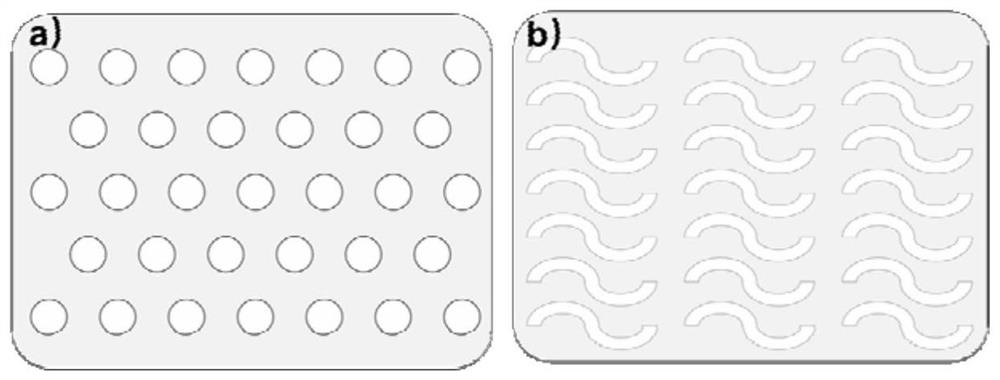

[0037] Step 2. Prepare circular holes arranged in an array and evenly distribute in the magnesium alloy film by laser processing, such as figure 1 shown in (a).

[0038] Step 3: Preforming the magnesium alloy film into a U-shape with a hard alloy mold, and then performing vacuum stress relief annealing at 200° C. for 1 hour to eliminate internal stress.

[0039] Step 4: Polyurethane is sprayed onto the inner surface of the magnesium alloy film to form a protective layer. Adopt concentration to be that 40% (mass fraction) in the hydrofluoric acid room temperature immersion 12h prepare smooth surface magnesium fluoride coating, thickness i...

Embodiment 2

[0043] In this embodiment, the preparation method of the degradable magnesium alloy oral biological barrier film comprises the following steps:

[0044] Step 1. The magnesium alloy thin plate containing Zn2% and Nd0.5% is rolled through four passes and vacuum annealed at 200° C. for 2 hours to obtain a magnesium alloy foil with a thickness of 200 μm.

[0045] Step 2. Prepare circular holes arranged in an array and evenly distribute in the magnesium alloy film by laser processing, such as figure 1 shown in (a).

[0046] Step 3: Preforming the magnesium alloy film into a U-shape with a hard alloy mold, and then performing vacuum stress relief annealing at 200° C. for 1 hour to eliminate internal stress.

[0047] Step 4: Polyurethane is sprayed onto the inner surface of the magnesium alloy film to form a protective layer. Adopt concentration to be that 40% (mass fraction) in the hydrofluoric acid room temperature immersion 12h prepare smooth surface magnesium fluoride coating, ...

Embodiment 3

[0051] In this embodiment, the preparation method of the degradable magnesium alloy oral biological barrier film comprises the following steps:

[0052] Step 1. The magnesium alloy sheet containing Zn2% and Nd0.5% is rolled five times and vacuum annealed at 200° C. for 2 hours to obtain a magnesium alloy foil with a thickness of 200 μm.

[0053] Step 2. Prepare S-shaped holes arranged in an array and evenly distribute in the magnesium alloy film by laser processing, such as figure 1 shown in (b).

[0054] Step 3: Preforming the magnesium alloy film into a U-shape with a hard alloy mold, and then performing vacuum stress relief annealing at 200° C. for 1 hour to eliminate internal stress.

[0055] Step 4: Polyurethane is sprayed onto the inner surface of the magnesium alloy film to form a protective layer. Adopt concentration to be that 40% (mass fraction) in the hydrofluoric acid room temperature immersion 12h prepare smooth surface magnesium fluoride coating, thickness is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com