Aerosol type siloxane modified waterproof leak-repairing material and preparation method thereof

A siloxane modification and aerosol technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, packaging objects under special gas conditions, etc., to achieve good storage stability and workability, improve service life, and hydrophobicity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

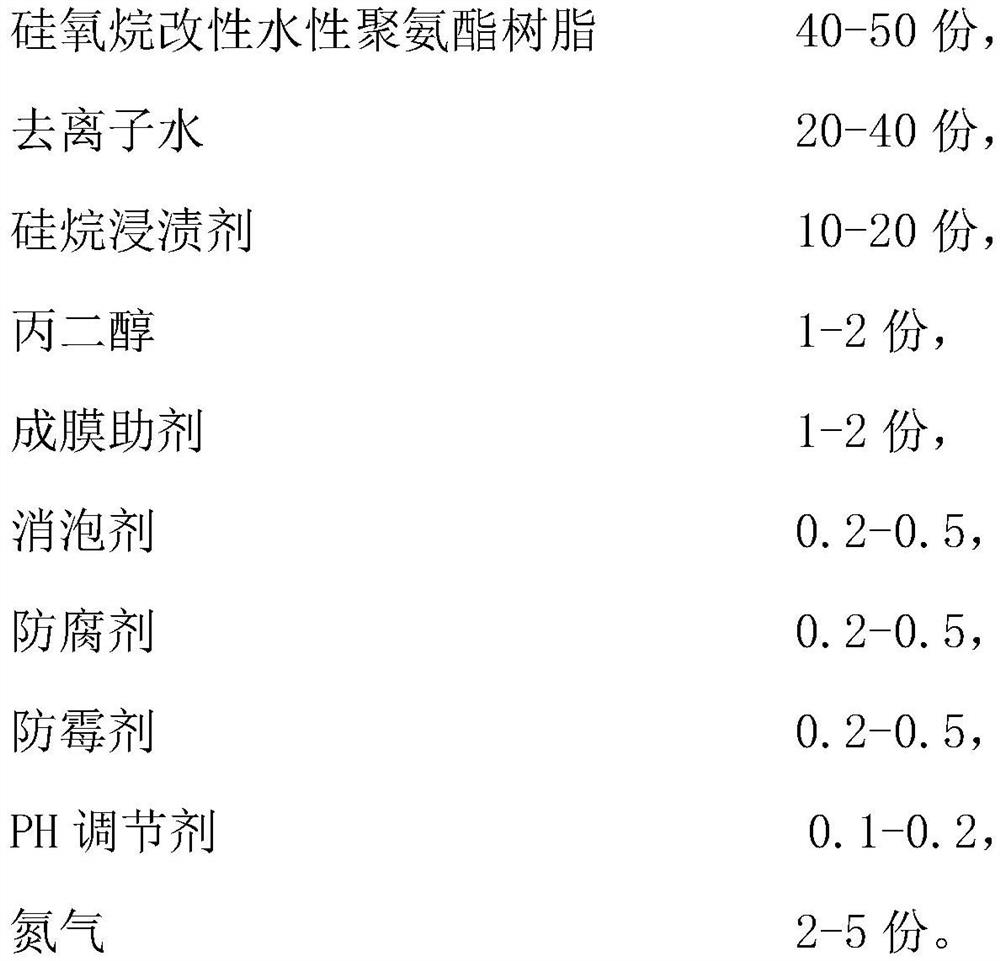

[0032] An aerosol-type siloxane-modified waterproof leakage-remediating material, which consists of the following components in parts by weight:

[0033]

[0034] In this embodiment, the solid content of the water-based silicone-modified polyurethane resin is 50%, the particle size is 46nm, the minimum film-forming temperature MFT is 7°C, and the mass fraction of silicone is 4%.

[0035] In an optional embodiment, the silane impregnating agent used is an emulsion of isobutyltriethoxysilane with a solid content of 40%.

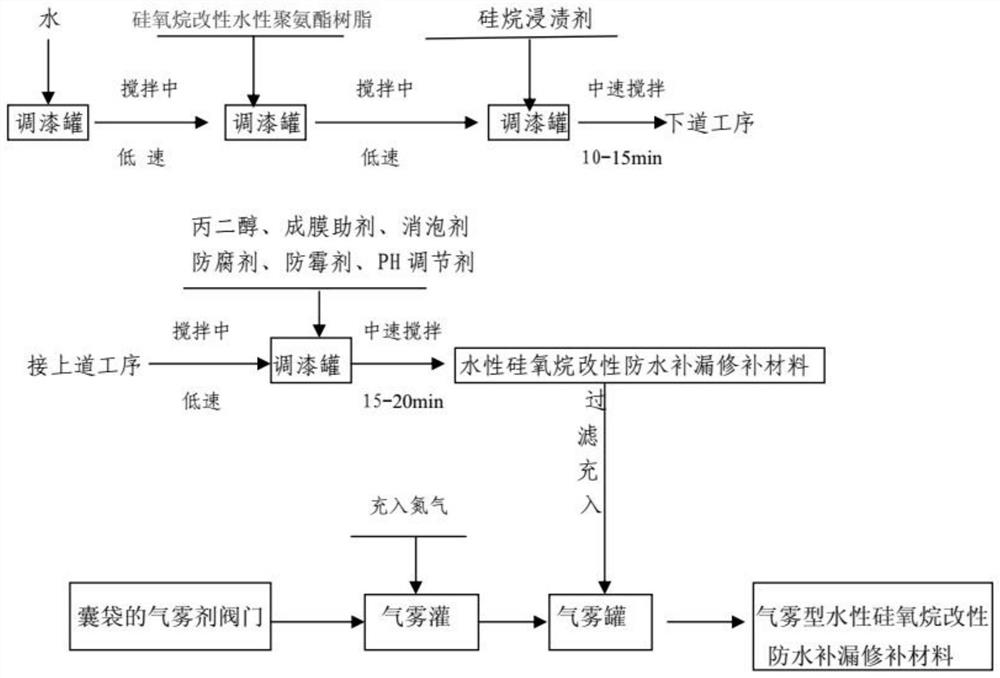

[0036] In this embodiment, the specific preparation method of the aerosol-type siloxane-modified waterproof leak-trapping material is as follows:

[0037] Step 1: Put the siloxane-modified water-based polyurethane resin and deionized water weighed in parts by weight in a container, then add the silane impregnating agent in order under stirring at a low speed of 350 rpm, and press 850 rpm Quickly disperse for 12 minutes to ensure uniform dispersion;

[0038...

Embodiment 2

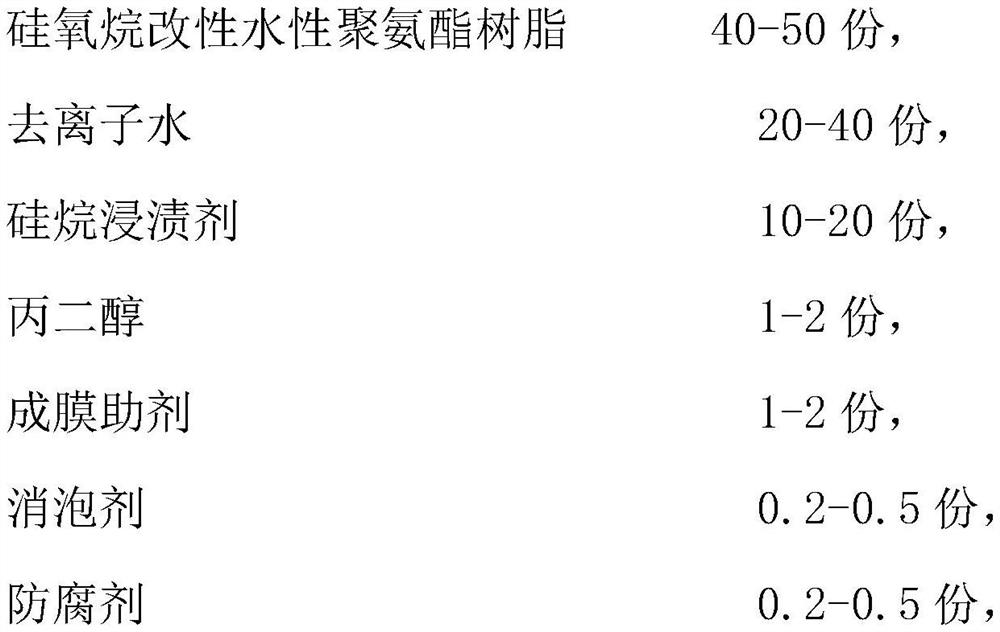

[0042] An aerosol-type siloxane-modified waterproof leakage-remediating material, which consists of the following components in parts by weight:

[0043]

[0044]

[0045] In this example, the solid content of the water-based siloxane-modified polyurethane resin is about 50%, the required particle size is 35nm, the minimum film-forming temperature MFT is 7°C, and the mass fraction of siloxane is 5%.

[0046] In this embodiment, the silane impregnating agent used is isooctyltriethoxysilane emulsion with a solid content of 40%.

[0047] The specific preparation method of the aerosol-type siloxane modified waterproof leak-trapping material in this embodiment is as follows:

[0048] Step 1: Put the siloxane-modified water-based polyurethane resin and deionized water weighed in parts by weight in a container, then add the silane impregnating agent in order under stirring at a low speed of 400 rpm, and press 900 rpm Quickly disperse for 15 minutes to ensure uniform dispersion; ...

Embodiment 3

[0053] An aerosol-type siloxane-modified waterproof leakage-remediating material, which consists of the following components in parts by weight:

[0054]

[0055]

[0056] In an optional embodiment, the solid content of the waterborne siloxane-modified polyurethane resin is about 50%, the particle size is required to be 46nm, the minimum film-forming temperature MFT is 8°C, and the mass fraction of siloxane is 4%.

[0057] In an optional embodiment, the silane impregnating agent used is n-octyltriethoxysilane emulsion with a solid content of 40%.

[0058] The specific preparation method of the aerosol-type siloxane modified waterproof leak-trapping material in this embodiment is as follows:

[0059] Step 1: Put the siloxane-modified water-based polyurethane resin and deionized water weighed in parts by weight in a container, then add the silane impregnating agent in order under stirring at a low speed of 400 rpm, and press 900 rpm Quickly disperse for 15 minutes to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com