Perovskite thin film, preparation method and application

A perovskite and thin film technology, applied in the field of photoelectric functional materials, can solve the problems of low quality of perovskite thin films, and achieve the effect of avoiding damage and avoiding cross contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of perovskite film provided by the invention comprises the following steps:

[0032] (1) Provide a substrate and clean it;

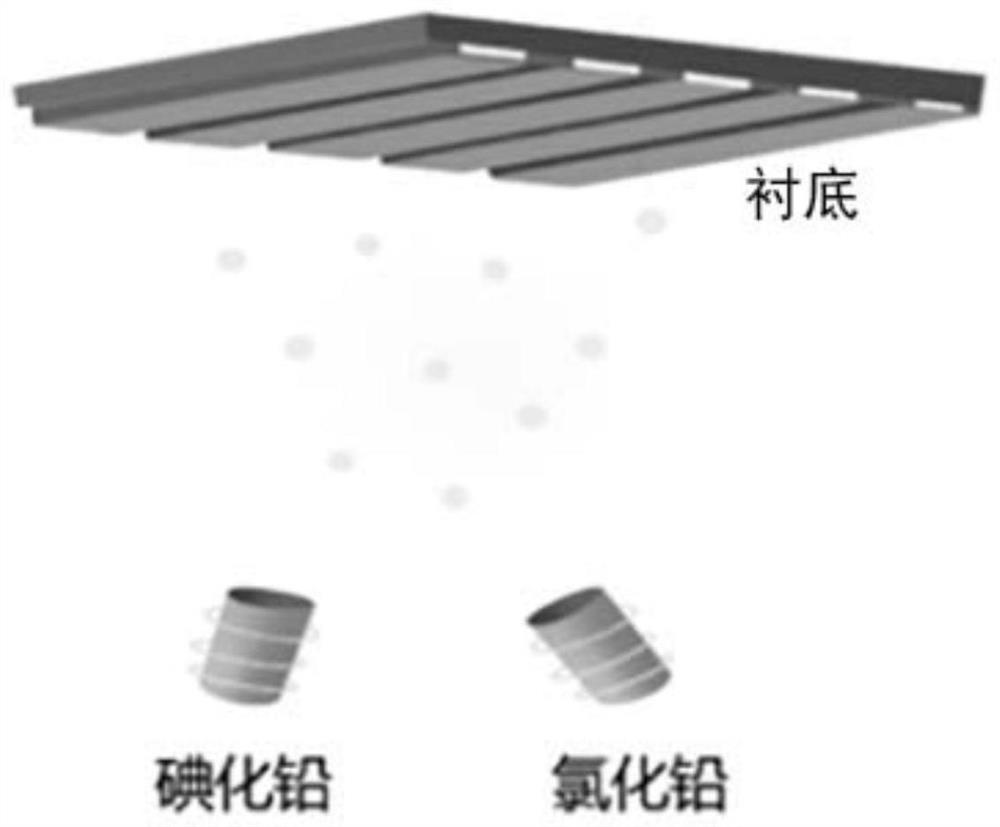

[0033] (2) Put the M powder and the lead iodide powder into the heating boat respectively, put the substrate and the heating boat into the vacuum coating machine and evacuate, place the heating boat under the substrate, and electrically heat the heating boat to make the M powder and the heating boat The lead iodide powder is volatilized to obtain the lead source film;

[0034] (3) Transfer the substrate to another cavity, and vapor-deposit a layer of amine salt on the lead source film;

[0035] (4) annealing to obtain a perovskite film;

[0036] In step (1), the material of the substrate is not specifically limited, and it can be any suitable substrate. The process of cleaning the substrate is to use glass cleaning solution, deionized water, ethanol and isopropanol to ultrasonically clean, then blow Dry for later use, the...

Embodiment

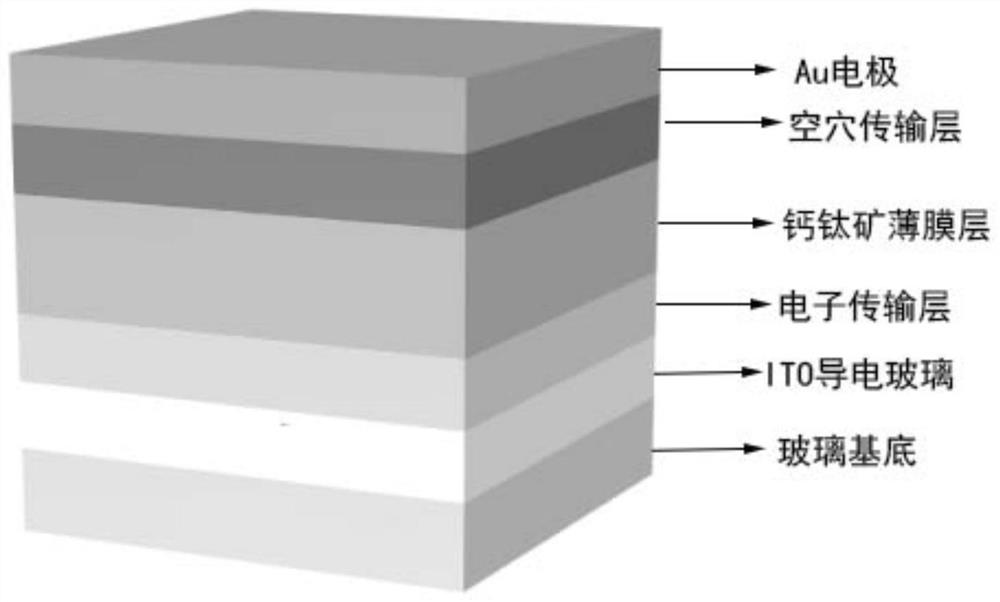

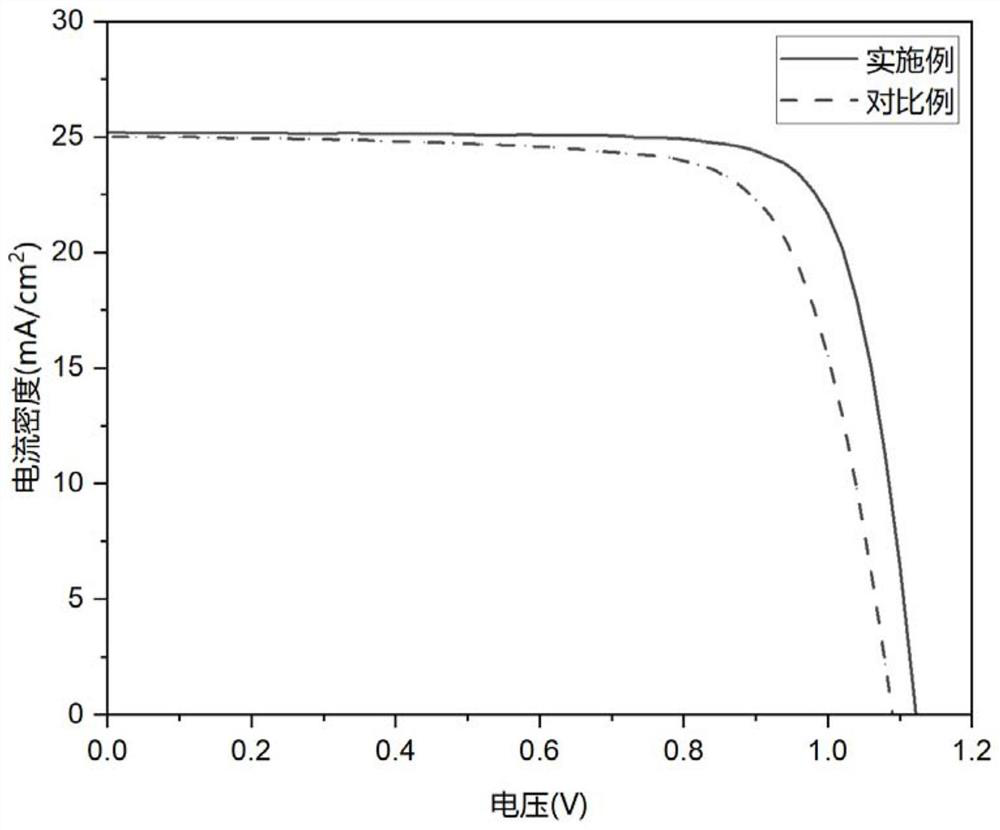

[0045] The substrate was ultrasonically cleaned with glass cleaning solution, deionized water, ethanol and isopropanol, dried, and treated with ultraviolet-ozone for 15 minutes. The substrate was ITO conductive glass with a glass substrate. Colloidal tin oxide particles were spin-coated on ITO conductive glass to form an electron transport layer. The spin-coating speed was 3000rpm, and the spin-coating time was 30s; Transfer to the chamber of the vacuum coating machine. Weigh 10g of lead chloride powder and 10g of lead iodide powder and place them in the heating boat respectively, place the heating boat in the cavity of the vacuum coating machine, place the heating boat under the substrate, evacuate until the vacuum degree is less than 1Pa, and use a DC power supply Direct current is applied to the heating boat, and the temperature of the heating boat rises under the thermal effect of the current. After the temperature reaches the boiling point of lead chloride and lead iodide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com