Lysinibacillus sp. With high caproic acid yield and application thereof

The technology of Bacillus lysine and Bacillus, which is applied in the field of winemaking, can solve the problems of poor quality of basic wine, low acid-producing ability, and low number of degraded pit mud caproic acid bacteria, and achieves stable quality and reduced ethyl lactate content. , the effect of increasing the number of Bacillus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

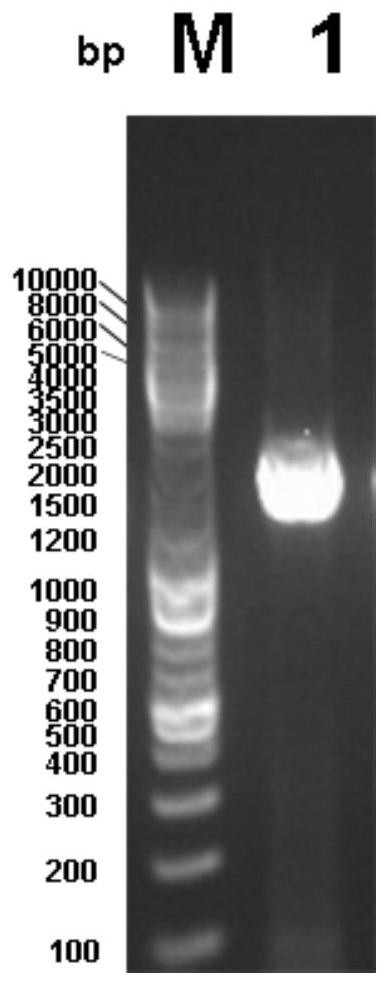

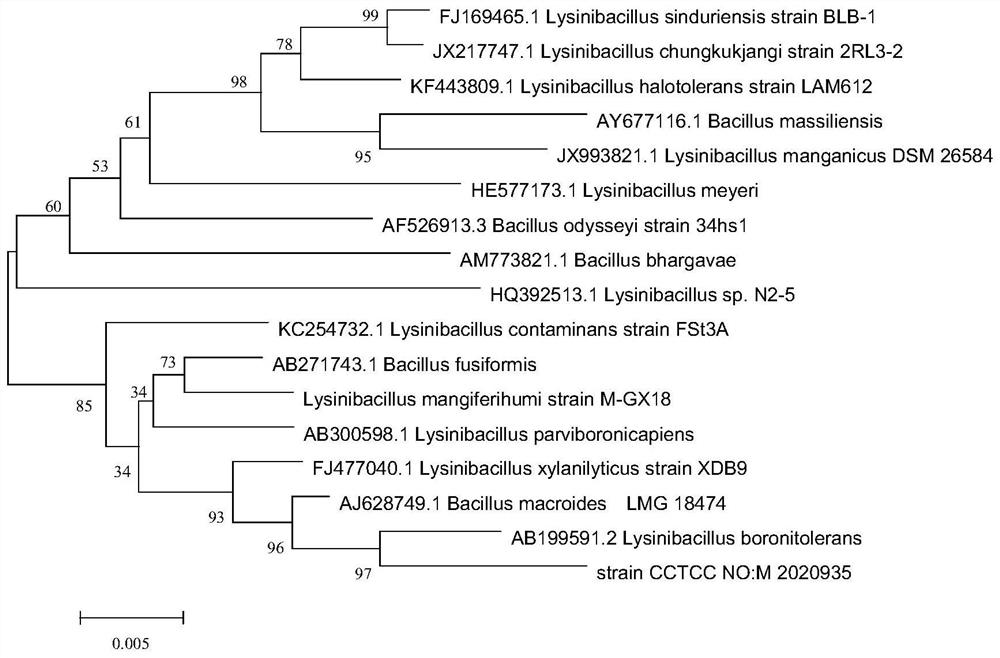

[0052] The screening and identification of embodiment 1 lysine bacillus GJ-1

[0053] Sampling: From the cellar pool No. 0001 of Luzhou Laojiao 1573 National Treasure Cellar Group, the pit mud was collected by the five-point method.

[0054] Enrichment culture: fully mix the pit mud samples, take 30g of pit mud and dissolve them in 50mL of sterile water, place them in a constant temperature water bath at 80-85°C for 10-20min, add 450mL of EAM medium after cooling, and incubate at 30-35 Cultivate for 7-10 days at ℃. Select the test tubes that produce more air bubbles and have obvious copper sulfate color reaction for secondary enrichment culture, repeat the enrichment culture for 3 times, and select the enrichment culture medium with higher hexanoic acid production for primary screening.

[0055] Primary screening: Dilute the enriched bacterial suspension in 6 gradients, take 25 microliters of coated plates, and place them upside down in a constant temperature incubator at 35°...

Embodiment 2

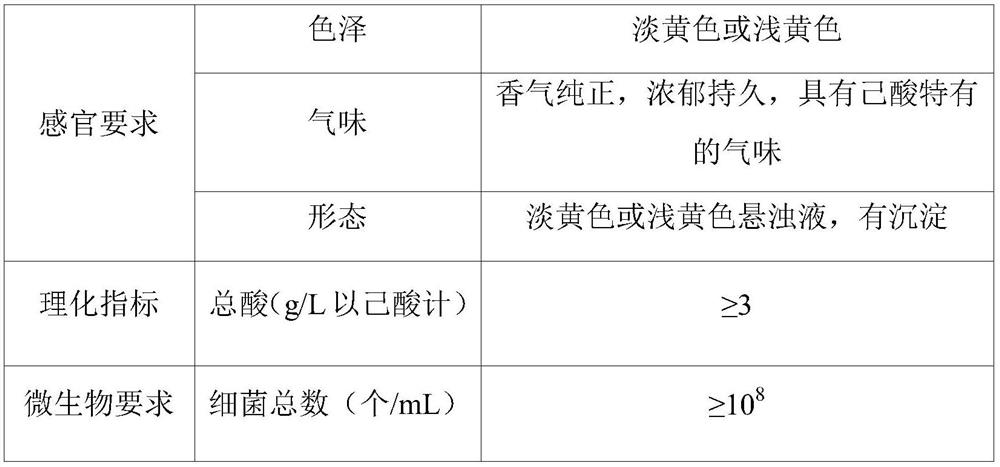

[0060] The expanded culture of embodiment 2 lysine bacillus GJ-1

[0061] a. Activation and proliferation culture of Bacillus lysinica GJ-1

[0062] Inoculate the strain of Bacillus lysinica GJ-1 that has been screened into the growth medium of Clostridium slantii in test tubes under aseptic conditions, culture at a constant temperature of 32-38°C for 2-3 days to activate, and then inoculate it into the eggplant bottle of Clostridium slant In the bacterial proliferation medium, culture at a constant temperature of 32-38°C for 2-3 days, wash the bacteria on the slant medium of the eggplant bottle with sterile water, and make a bacterial suspension, so that the initial concentration of the number of bacteria is ≥1.0×10 10 individual / mL.

[0063] b. Bacillus lysinica GJ-1 seed tank culture

[0064] Inoculate the bacterial suspension obtained in step a into the seed tank of the EAM liquid medium with an inoculum amount of 1-10%, and cultivate at a constant temperature of 32-38°C...

Embodiment 3

[0073] Example 3 Bacillus lysinica GJ-1 bacterial solution applied to cellar maintenance

[0074] The method for maintaining the cellar with Bacillus lysinica GJ-1 is to uniformly punch holes on the wall of the cellar with a nail with a diameter of 1cm, at an angle of 30-45°, at a depth of 2cm, at an interval of 10-20cm, and spray 10kg of A mixed solution of Bacillus lysinica GJ-1 and 5kg tail water. Smooth the hole, put the fermented grains into the cellar and ferment for 60 days.

[0075] Table 2 The ways in which Bacillus lysinica GJ-1 bacterial solution is applied to cellar maintenance

[0076] cellar number 1#~3# 4#~6# Way Conservation with bacterial solution unmaintained

[0077] According to the above two schemes in Table 2, 1#~3# cellar ponds were cured by Bacillus lysinus and then fermented with fermented grains to produce wine, and 4#~6# were not cured as a control, and the properties and properties of the cellar mud were compared after 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com