Micromolecular sodium hyaluronate and micromolecular sodium hyaluronate composition for improving skin aging and sensitivity and application of micromolecular sodium hyaluronate and micromolecular sodium hyaluronate composition

A technology of sodium hyaluronate and skin improvement, applied in food science and other fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In the present invention, small molecule sodium hyaluronate is a mixture of small molecule sodium hyaluronate obtained after hydrolysis of sodium hyaluronate with an average molecular weight distribution in the range of 80KDa to 800KDa, preferably prepared by the following steps: hyaluronic acid The sodium solid is hydrolyzed for 5-15 hours under the condition of hydrogen peroxide.

[0027] The present invention has no special limitation on the source of the sodium hyaluronate solid, and the source of the sodium hyaluronate solid well known in the art can be used. In the embodiment of the present invention, the average molecular weight of the sodium hyaluronate solid is preferably 0.1-1 MDa; the purity of the sodium hyaluronate solid is preferably ≥99%. The preparation method of the sodium hyaluronate solid preferably comprises the following steps:

[0028] (a) inoculating yeast in a liquid medium for fermentation and culturing to obtain a fermentation broth;

[0029]...

Embodiment 1

[0046] Preparation method of small molecule sodium hyaluronate

[0047] (a) Fermentation: using yeast as the strain, first take the slant strain and inoculate it on the seed medium, and cultivate it at 37° C. for 20 hours to obtain the yeast liquid;

[0048] (b) Inoculate the obtained yeast liquid into the liquid medium of the fermenter, the volume ratio of the bacterial liquid to the medium is 1:8, the ventilation rate is 0.8vvm, the stirring speed is 250rpm, the culture temperature is 37°C, and the fermentation time is 60h, obtain fermented liquid;

[0049] (c) Separation: After the fermentation broth is adsorbed by 300-mesh activated carbon, 80% ethanol is added for precipitation, and the crude sodium hyaluronate is obtained by filtration;

[0050] (d) Refining: the crude sodium hyaluronate is washed with 80% ethanol, heated and dried to obtain 99% sodium hyaluronate;

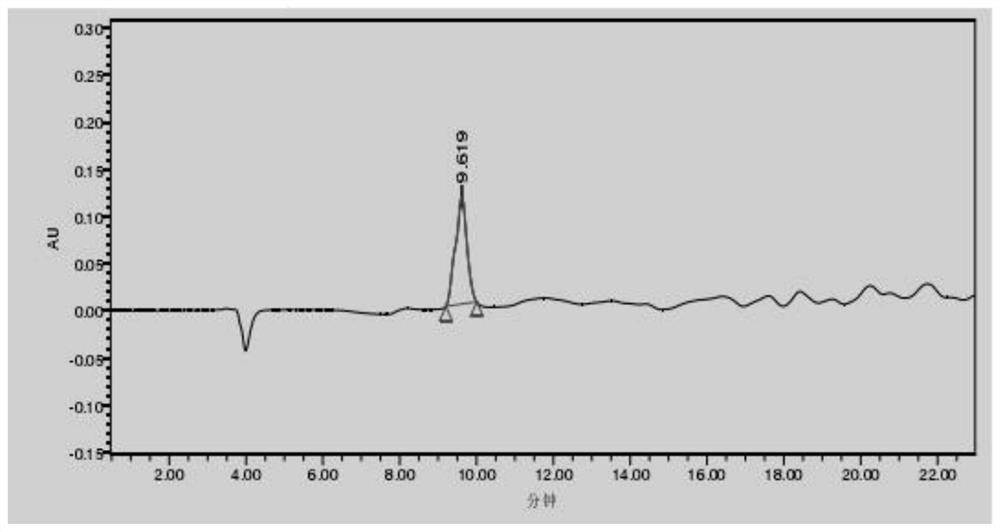

[0051] (e) Hydrolysis: hydrolyze the solid sodium hyaluronate with an average molecular weight of 0.1MD...

Embodiment 2

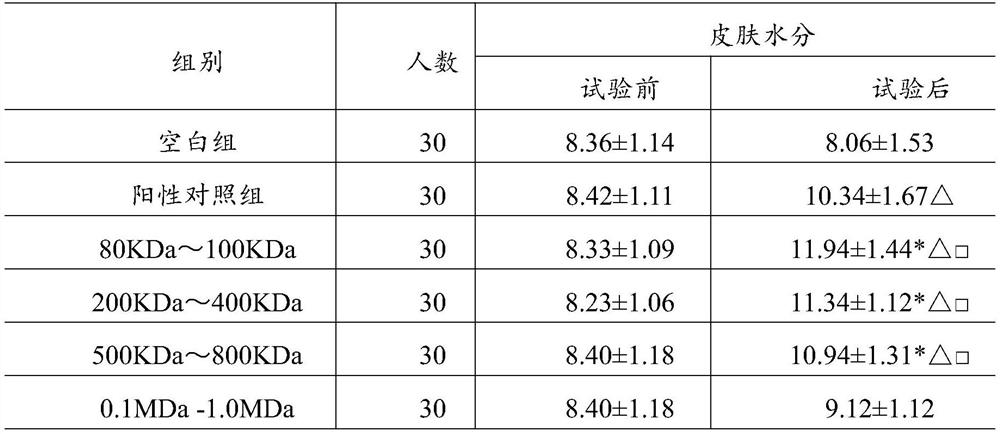

[0055] The small molecule sodium hyaluronate hydrolyzate was prepared according to the method of Example 1, the only difference being that the hydrolysis time was set at 8h and 9h respectively. The average molecular weight of the hydrolyzed sodium hyaluronate was measured according to the method of Example 1. The results show that the average molecular weight of the water molecule sodium hyaluronate prepared by the method is 200KDa-400KDa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com