Doped and coated sodium ion battery positive electrode material and preparation method thereof

A technology for sodium ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing battery cycle performance, phase transition of electrode materials, irreversible de-intercalation, etc. The effect of improving electronic conductivity, improving cycle performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

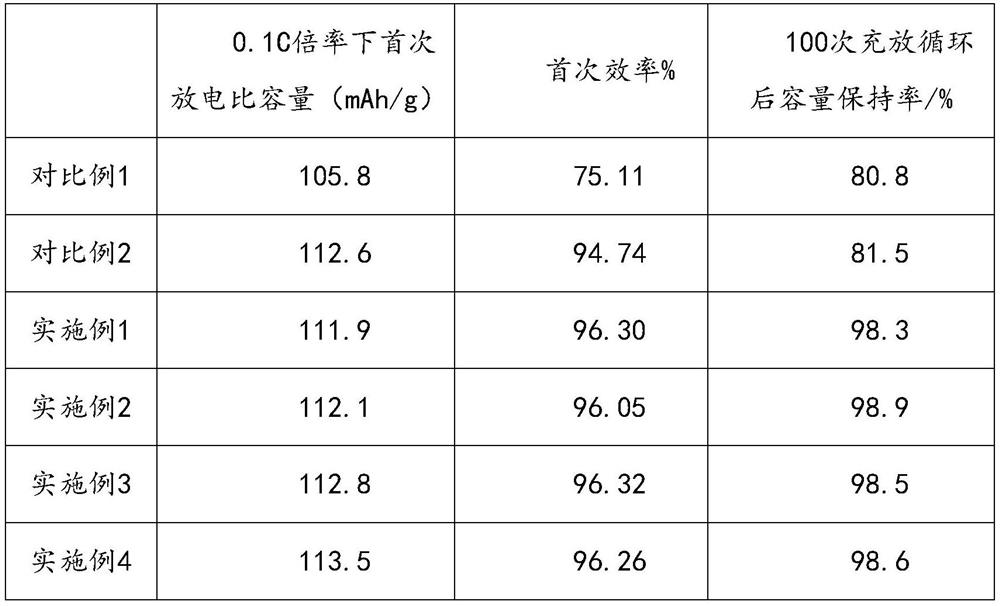

Examples

Embodiment 1

[0031] The nickel sulfate and manganese sulfate solutions are formulated into a 2mol / L salt solution according to the molar ratio of nickel ions and manganese ions at 1:2. Inject the prepared salt solution into the reaction kettle with a speed of 360rpm at a speed of 10L / h. At the same time, dissolve 0.4mol / L sodium metaaluminate solution and vanadium pentoxide in hydrogen at a speed of 2.5L / h. The 0.4mol / L sodium vanadate solution prepared by sodium oxide is added in the reaction kettle, and the complexing agent ammonia solution of 2mol / L and the precipitating agent sodium hydroxide solution of 4mol / L are added to the reaction kettle at the same time to carry out co-precipitation under an inert atmosphere. Precipitation reaction, keep the pH value between 11.4-12, control the reaction temperature at about 60°C, react for 60h, then centrifuge and filter to separate, wash to neutral, dry at 160°C for 8h, and sieve to get the molecular formula Ni 0.3 mn 0.6 V0.05 Al 0.05 (OH) ...

Embodiment 2

[0036] The nickel chloride and manganese chloride solutions are prepared into a 2mol / L salt solution according to the molar ratio of nickel ions and manganese ions at 1:9. At a rate of 15L / h, inject the prepared salt solution into a reaction kettle with a rotation speed of 450rpm. At the same time, inject 0.2mol / L sodium metaaluminate solution at a rate of 1.5L / h and the The 0.2mol / L sodium vanadate solution prepared by dissolving ammonium vanadate in sodium hydroxide is added in the reactor, and the complexing agent ammonia solution of 2mol / L and the precipitating agent sodium hydroxide of 4mol / L are added in the reactor at the same time Co-precipitate the solution under an inert atmosphere, keep the pH value between 11.0-11.8, control the reaction temperature at about 48°C, react for 100h, then centrifugally filter and separate, wash to neutral, dry at 100°C for 14h, and sieve The molecular formula is obtained as Ni 0.1 mn 0.88 V 0.01 Al 0.01 (OH) 2 Precursor materials ...

Embodiment 3

[0041] The nickel acetate and manganese acetate solutions are prepared into a 2mol / L salt solution according to the molar ratio of nickel ions and manganese ions at 4:1. Inject the prepared salt solution into the reaction kettle with a speed of 400rpm at a speed of 6L / h. The 0.2mol / L sodium vanadate solution prepared by dissolving vanadium oxide in sodium hydroxide is added to the reaction kettle, and at the same time, 2mol / L complexing agent ammonia solution and 4mol / L precipitant sodium hydroxide solution are added to the reaction kettle Carry out co-precipitation reaction under inert atmosphere, keep the pH value between 10.6-11.0, control the reaction temperature at about 50°C, react for 80h, then separate by centrifugal filtration, wash to neutral, dry at 90°C for 20h, and sieve to obtain The molecular formula is Ni 0.72 mn 0.18 V 0.01 Al 0.09 (OH) 2 Precursor materials for sodium-ion batteries;

[0042] Mix the above-mentioned sodium ion battery precursor with sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com