Special multi-stage controlled-release compound microbial fertilizer for rice and preparation method thereof

A compound microorganism and rice technology, applied in the field of multi-level controlled-release compound microbial fertilizer for rice and its preparation, can solve the problem of not being able to adapt to the complex growth environment of rice, the coating material not being able to adapt to the flooding environment of rice, slow-release fertilizer releasing nutrients and Microbial flora cannot fully conform to the absorption rules of rice nutrients, etc., to achieve the effects of reducing agricultural non-point source pollution, saving labor costs, and improving fertilizer utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

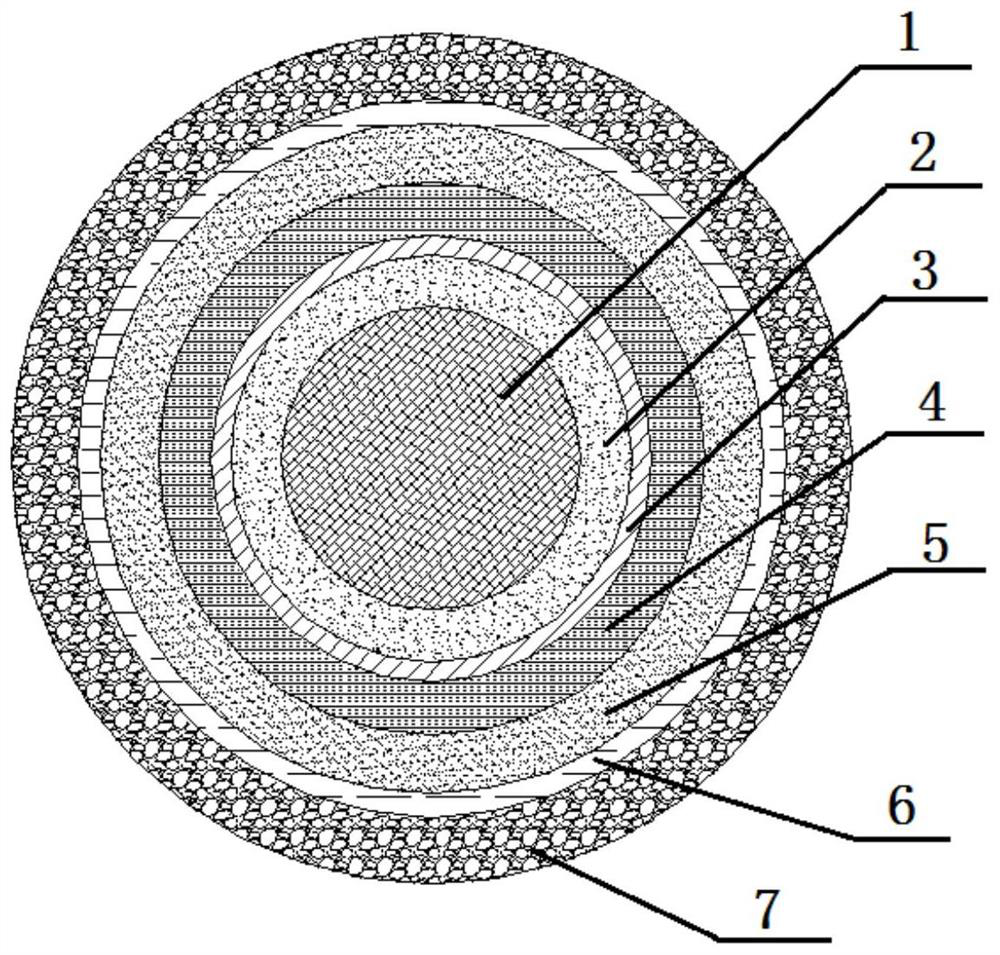

[0037] Special multi-level controlled-release compound microbial fertilizer for rice, its structure from inside to outside is as follows: figure 1 As shown, it includes: rice booting fertilizer layer 1, dry field nutrient bacterial agent layer 2, water-soluble sensitive layer 3 with a pH value greater than or equal to 6, rice seedling fertilizer layer 4 with a pH value less than 6, paddy field biocontrol bacterial agent layer 5, hydrolyzed bag Film layer 6, decomposed microorganism / organic fertilizer layer 7;

[0038] Prepare the materials to form the layers:

[0039] The first layer is paddy rice booting fertilizer layer 1, and used material is the mixture of nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, silicon fertilizer, zinc fertilizer, and the weight ratio of nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, silicon fertilizer, zinc fertilizer is 60:10:15:10: 5. The nitrogen fertilizer used is potassium nitrate, the phosphate fertilizer is ...

Embodiment 2

[0054] Special multi-stage controlled release compound microbial fertilizer for rice, its structure is identical with embodiment 1;

[0055] Prepare the materials to form the layers:

[0056] The first layer is paddy rice booting fertilizer layer 1, and used material is the mixture of nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, silicon fertilizer, zinc fertilizer, and the weight ratio of nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, silicon fertilizer, zinc fertilizer is 60:15:15:15: 5. The nitrogen fertilizer used is urea, the phosphate fertilizer is monoammonium phosphate, the potassium fertilizer is potassium nitrate, the silicon fertilizer is sodium silicate, and the zinc fertilizer is EDTA-Zn. Mix these five fertilizers evenly for use;

[0057] The second layer is dry field nutrient bacterial agent layer 2, and the nutritional bacterium agent used is Bacillus megaterium bacterial powder and jelly-like Bacillus bacterial powder, and the ...

Embodiment 3

[0066] Special multi-stage controlled release compound microbial fertilizer for rice, its structure is identical with embodiment 1;

[0067] Prepare the materials to form the layers:

[0068] The first layer is paddy rice booting fertilizer layer 1, and used material is the mixture of nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, silicon fertilizer, zinc fertilizer, and the weight ratio of nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, silicon fertilizer, zinc fertilizer is 60:10:15:10: 5. The selected ammonium chloride, phosphate fertilizer is monoammonium phosphate, potash fertilizer is potassium nitrate, silicon fertilizer is potassium silicate, and zinc fertilizer is zinc sulfate. Mix these five fertilizers evenly for use;

[0069] The second layer is dry field nutrient bacterial agent layer 2, and the nutritional bacterium agent used is Bacillus megaterium bacterial powder and jelly-like Bacillus bacterial powder, and the mass ratio of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com