High-temperature-resistant powder coating and preparation method thereof

A technology of powder coating and high temperature resistance, which is applied in the direction of powder coating, polyester coating, coating, etc., which can solve the problems of large processing pollution, poor compatibility, and large amount of silicone resin, so as to improve the oxidation resistance and durability. High temperature performance, strong oxidation resistance and high temperature resistance, excellent high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

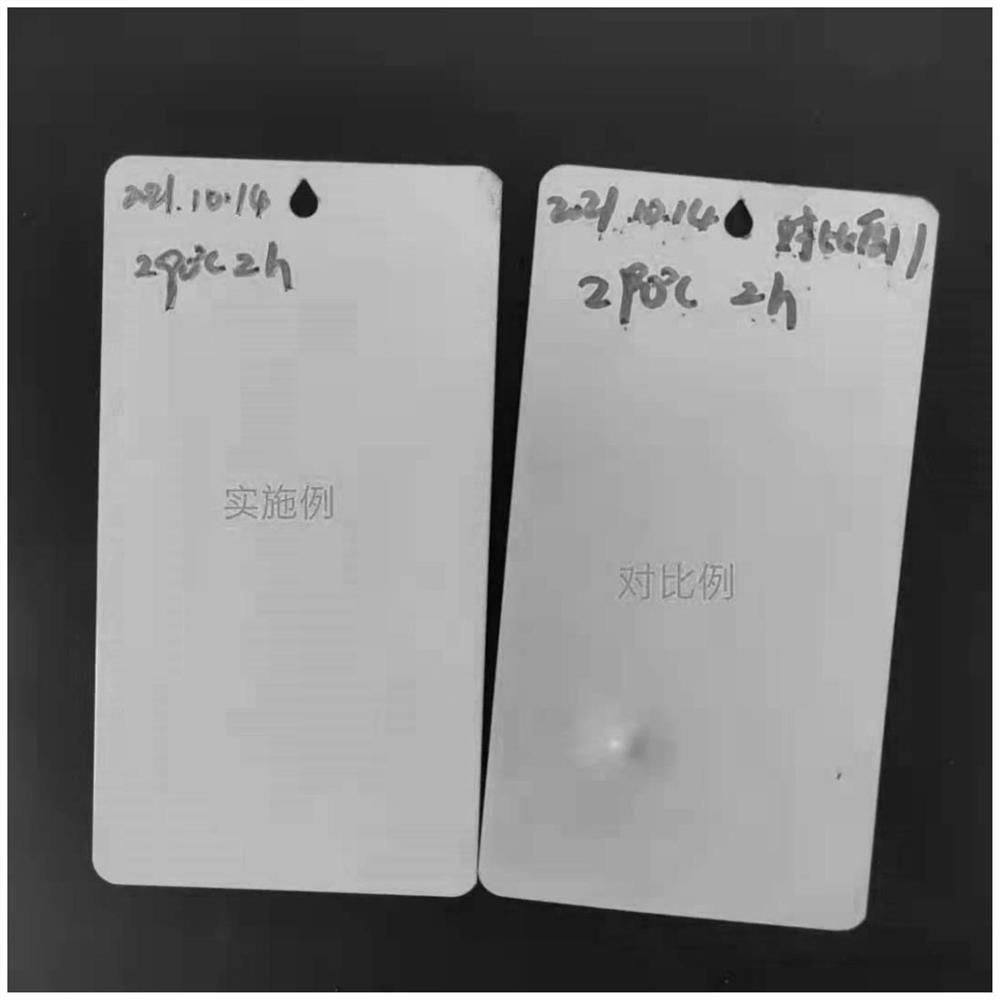

Image

Examples

preparation example Construction

[0032] The preparation method of No. 3 carboxyl-terminated allyl polyether modified silicone oil: under the protection of nitrogen, the isopropanol solution of chloroplatinic acid: 3mg, allyl alcohol polyether H 2 C=CHCH 2 -O-(C 2 h 4 O-) 8 -(C 3 h 6 O-) 0 : 20g, phenyl hydrogen-containing silicone oil with a molecular weight of 8000 (phenyl content: 85%, hydrogen content: 0.1%): 50g, put into the reaction bottle, react at 80°C for 10h, and obtain 70g of allyl alcohol polyether modified phenyl silicone oil , and then add 10.8g of terephthalic acid, and react at 130°C for 6h to obtain carboxyl-terminated modified phenyl silicone oil.

[0033] No. 4 carboxyl allyl polyether modified silicone oil: under the protection of nitrogen, the isopropanol solution of chloroplatinic acid: 4mg, allyl alcohol polyether H 2 C=CHCH 2 -O-(C 2 h 4 O-) 0 -(C 3 h 6 O-) 0 : 7g, phenyl hydrogen-containing silicone oil with a molecular weight of 3000 (phenyl content: 50%, hydrogen conte...

Embodiment 2

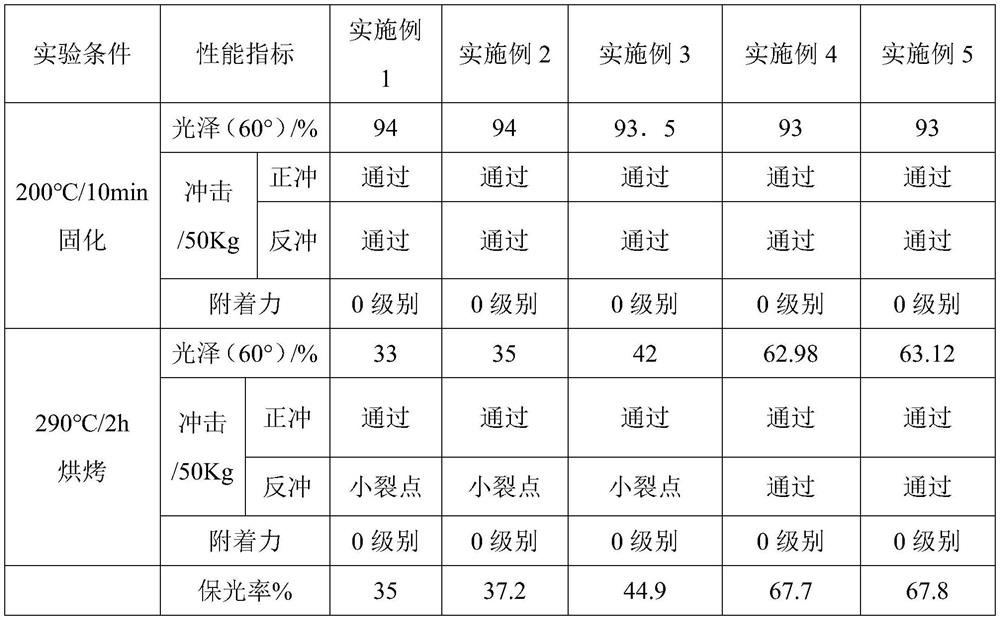

[0036] Example 2 Preparation of high temperature resistant powder coating.

[0037] Weigh the polyester resin, curing agent, barium sulfate, rutile titanium dioxide, leveling agent, brightener, modified phenyl silicone oil into the mixing tank and mix evenly according to the formula weight percentage in Table 1 and Table 2. The above materials are melted and extruded through an extruder, and the temperature of the melted extrusion of the extruder is 100-120°. After cooling through the tableting roller, crushing, grinding and pulverization by a pulverizer, cyclone separation, and grading and sieving, the examples are obtained. 1~11 finished high temperature resistant powder, the particle size is 30~40μm.

[0038] Weigh the polyester resin, curing agent, barium sulfate, rutile titanium dioxide, leveling agent and brightener according to the weight percentage of the formula in Table 2, put them into the mixing tank and mix evenly, melt and extrude the above materials through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com