Heavy metal repairing agent as well as preparation method and application thereof

A restoration agent and heavy metal technology, applied in the field of environmental restoration, can solve problems such as the restoration effect of various heavy metal pollutants that have not been mentioned, and achieve the effect of improving restoration effect, reducing preparation cost, and reducing site restoration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

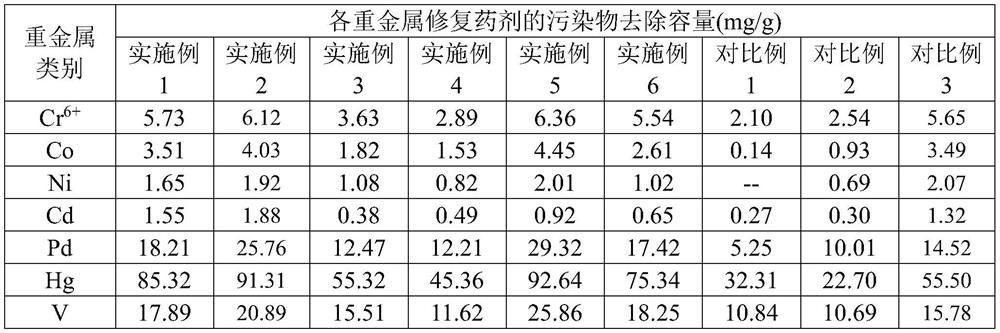

Examples

Embodiment 1

[0064] This embodiment provides a heavy metal restoration agent and a preparation method thereof. The raw material used in the preparation method is the magnetic separation tailings produced by a gold smelter, calculated as oxides, wherein the mass fractions of iron, copper, and zinc are respectively : 49.67%, 0.25%, 1.61%, the preparation method comprises the following steps:

[0065] (1) Perform pretreatment, reduction treatment, pickling treatment and suction filtration on the magnetic separation tailings in sequence to obtain iron-based polymetallic; the pretreatment specifically includes: grinding the material and passing it through a 60-mesh sieve; Calcined and oxidized in a muffle furnace for 4 hours; the reduction treatment is as follows: placing the material in a tube furnace and feeding H at 900°C 2 Reaction for 6 hours; the pickling treatment specifically includes: placing the material in a hydrochloric acid solution with a concentration of 5 wt%, and pickling for 1...

Embodiment 2

[0069] This embodiment provides a heavy metal restoration agent and a preparation method thereof. The raw material used in the preparation method is cyanide tailings produced by a gold wet smelter. Calculated as oxides, the mass fractions of iron, copper, and zinc Respectively: 43.14%, 0.28%, 0.22%. The preparation method comprises the following steps:

[0070] (1) Carry out pretreatment, reduction treatment, pickling treatment and suction filtration sequentially on the cyanide tailings to obtain iron-based polymetallic; the pretreatment is specifically: after the material is ground and sieved through 150 mesh, it is sieved at 1000 ° C Calcined and oxidized in a muffle furnace for 4 hours; the reduction treatment specifically includes: placing the material in a tube furnace, and passing H at 800°C 2 Reaction for 8 hours; the pickling treatment specifically includes: placing the material in a hydrochloric acid solution with a concentration of 2 wt%, and pickling for 2 hours;

...

Embodiment 3

[0074] This embodiment provides a heavy metal restoration agent and a preparation method thereof. The raw material used in the preparation method is the magnetic separation tailings produced by a gold smelter, calculated as oxides, wherein the mass fractions of iron, copper, and zinc are respectively : 49.67%, 0.25%, 1.61%, the preparation method comprises the following steps:

[0075] (1) Carry out pretreatment, reduction treatment, pickling treatment and suction filtration on the tailings of magnetic separation in sequence to obtain iron-based polymetallic; the specific pretreatment is: after the material is ground and sieved through 50 mesh, it is heated at 1000 ° C Calcined and oxidized in a muffle furnace for 4 hours; the reduction treatment is as follows: placing the material in a tube furnace and feeding H at 1000°C 2 Reaction for 4 hours; the pickling treatment specifically includes: placing the material in a sulfuric acid solution with a concentration of 10 wt%, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com