Method for enriching precious metal from poor impurity material

A precious metal, impurity-poor technology, applied in the field of precious metal enrichment, can solve the problems of difficult disposal of waste liquid, difficulty in removing silicon, and high value, and achieve the effect of not easily broken and speeding up the leaching reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

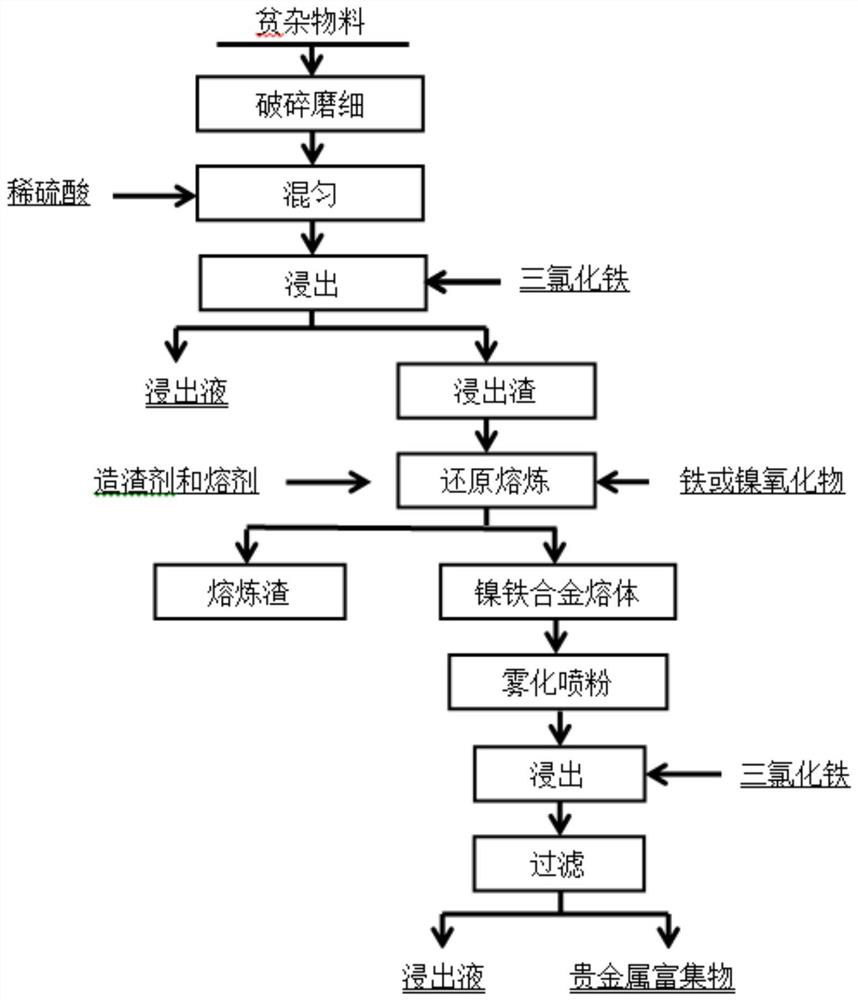

[0028] Referring to the accompanying drawings, (1) Wet leaching of nickel: claim 2000g of poor miscellaneous material is crushed and ground, adding concentration is 20% dilute sulfuric acid and the amount is 5 times of the weight ratio of poor miscellaneous material, adding anhydrous ferric chloride in batches for leaching Nickel and iron, the total addition amount is 2.5 times of the weight ratio of the impurity-poor material, leaching at room temperature for 3 hours, filtering and washing to obtain leaching residue and leaching solution; the leaching rate of nickel in the leaching solution is 92.36%;

[0029] (2) Pyromelting desiliconization: Mix the leaching slag with nickel oxide, slagging agent, and flux. The amount of nickel oxide added is 1.0 times the weight of the leaching slag, and the amount of slagging agent lime added is 0.35 times the weight of the leaching slag. , the flux is calcium fluoride and sodium carbonate, the addition amount is 0.2 times the weight of th...

Embodiment 2

[0032] Referring to the accompanying drawings, (1) wet leaching of nickel: claim 1000g of poor miscellaneous material is crushed and finely ground, adding a concentration of 25% dilute sulfuric acid is 4 times the weight ratio of poor miscellaneous material, and then adds anhydrous ferric chloride in batches For leaching nickel, the total addition amount is 3 times of the weight ratio of the impurity-poor material, leaching at room temperature for 2 hours, filtering and washing to obtain slag and leachate; the leaching rate of nickel in the leachate is 90.25%;

[0033] (2) Pyromelting desiliconization: mix the leaching slag with nickel oxide, slagging agent, and flux, the amount of nickel oxide added is 0.8 times the weight of the leaching slag, the slagging agent is lime, and the amount of lime added is the weight of the leaching slag 0.25 times of 0.25 times, the flux is borax and calcium fluoride, the addition amount is 0.3 times of the leaching slag weight, the melting temp...

Embodiment 3

[0036]Referring to the accompanying drawings, (1) wet leaching of nickel: claim 5000g of poor miscellaneous material broken and finely ground, adding concentration is 30% dilute sulfuric acid amount is 3 times of lean miscellaneous material weight ratio, then adds anhydrous ferric trichloride in batches For leaching nickel and iron, the total addition amount is 4 times of the weight ratio of the impurity-poor material, leaching at room temperature for 4 hours, filtering and washing to obtain slag and leachate; the leaching rate of nickel in the leachate is 96.11%;

[0037] (2) Pyromelting desiliconization: mix the leaching slag with iron oxide, slagging agent, and flux, the amount of iron oxide added is 1.0 times the weight of the leaching slag, the slagging agent is lime, and the amount of lime added is leaching slag 0.3 times the weight, the flux is sodium carbonate and calcium fluoride, the addition amount is 0.2 times the weight of the leaching slag, the melting temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com