Polymer electrolyte with gas-phase flame-retardant function and battery

A technology of polymers and electrolytes, which is applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, organic electrolytes, etc. It can solve the problems that it is difficult to exert the gas phase flame retardant function, and the flame retardant polymer electrolyte matrix cannot effectively produce flame retardant volatiles. , to achieve the effects of excellent oxidation stability, excellent electrochemical performance and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

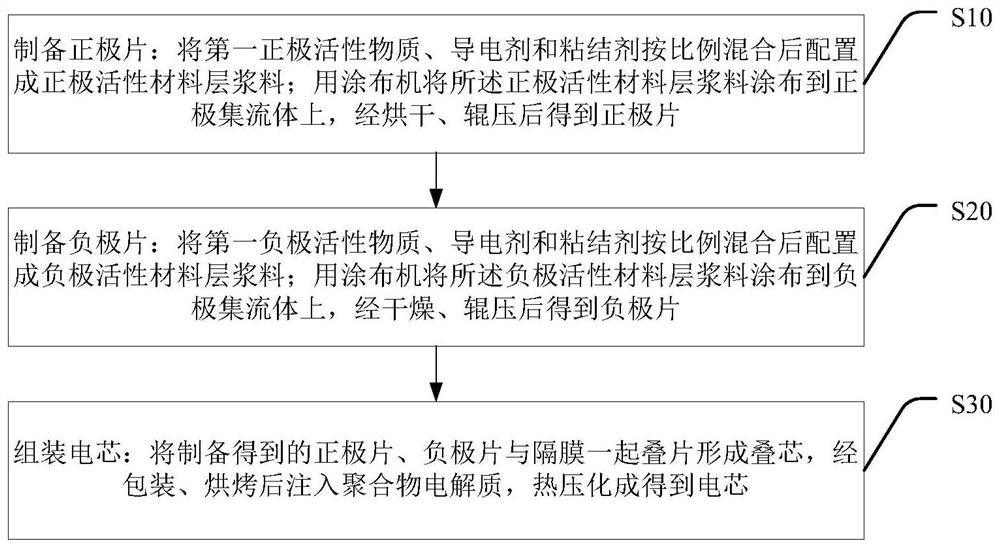

[0054] The embodiment of the present invention also provides a preparation method of the battery, such as figure 1 shown, including steps:

[0055] S10. Prepare a positive electrode sheet: mix the first positive electrode active material, the conductive agent and the binder in proportion to form a positive electrode active material layer slurry; use a coating machine to coat the positive electrode active material layer slurry on the positive electrode collector On the fluid, the positive electrode sheet is obtained after drying and rolling;

[0056] S20. Prepare a negative electrode sheet: mix the first negative electrode active material, the conductive agent and the binder in proportion to form a negative electrode active material layer slurry; use a coater to coat the negative electrode active material layer slurry on the negative electrode collector On the fluid, the negative electrode sheet is obtained after drying and rolling;

[0057] S30, assembling the battery cell: ...

Embodiment 1-6

[0066] Preparation of batteries containing monomers of non-flammable or flame-retardant substances with gas-phase flame retardant function

[0067] Preparation of positive electrode sheet: Lithium cobalt oxide, acetylene black and polyvinylidene fluoride are added to a stirring tank in a mass ratio of 97:1.8:1.2, and N-methylpyrrolidone solvent is added to stir and pass through a 200-mesh sieve to configure a positive electrode active material layer slurry, the solid content of which is 70wt%-75wt%; the positive electrode active material layer slurry is coated on the positive electrode current collector (aluminum foil) with a coating machine, dried at 120°C, and rolled to obtain a positive electrode sheet ;

[0068] Preparation of negative electrode sheet: 97.5wt% graphite (solid phase diffusion coefficient is 10-14), 0.7wt% conductive carbon black and 1.8wt% SBR are configured into negative electrode active material layer slurry (solid content is 40wt%-45wt%), Coat the negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com