Synthesis method and application of over-speed hole-filling copper plating leveling agent

A synthesis method and technology of leveling agent, applied in the direction of electrical connection of printed components, printed circuit components, etc., can solve the problems of low solubility of copper oxide powder, insufficient supply of copper sources, affecting production capacity, etc. Surface copper control ability and effect of improving plating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

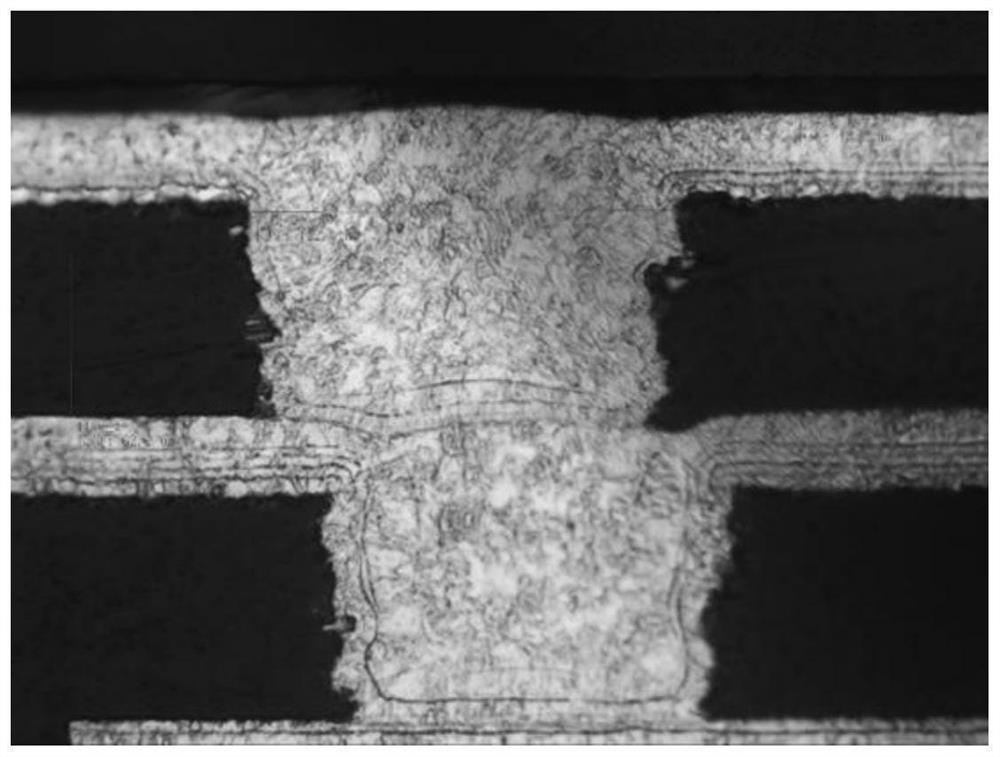

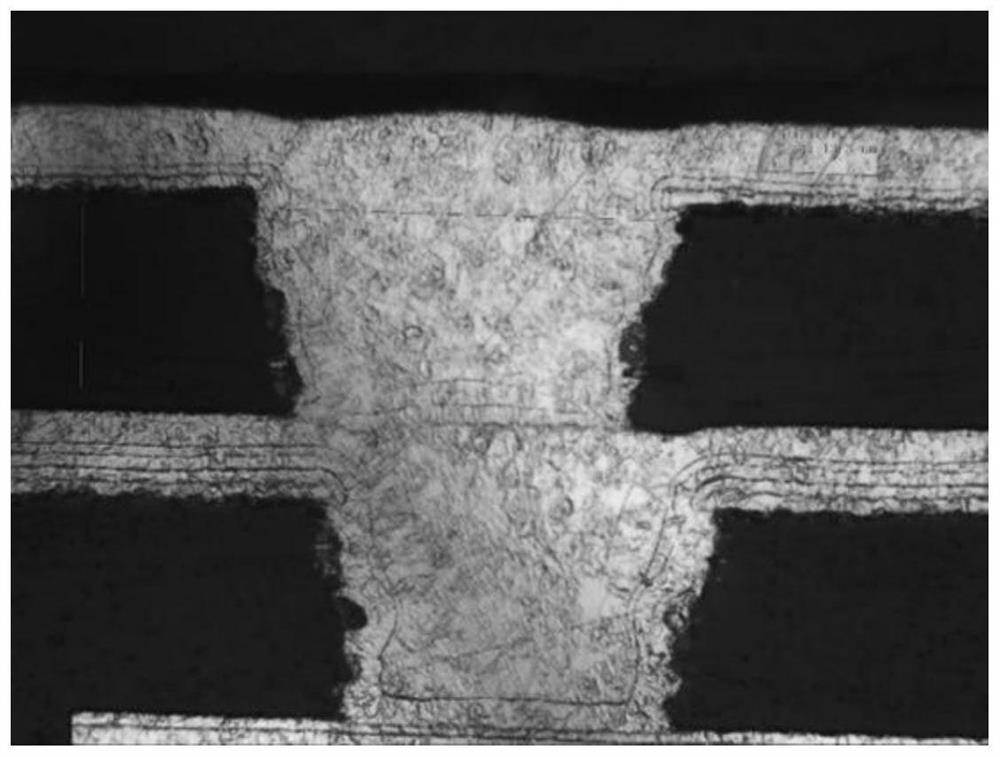

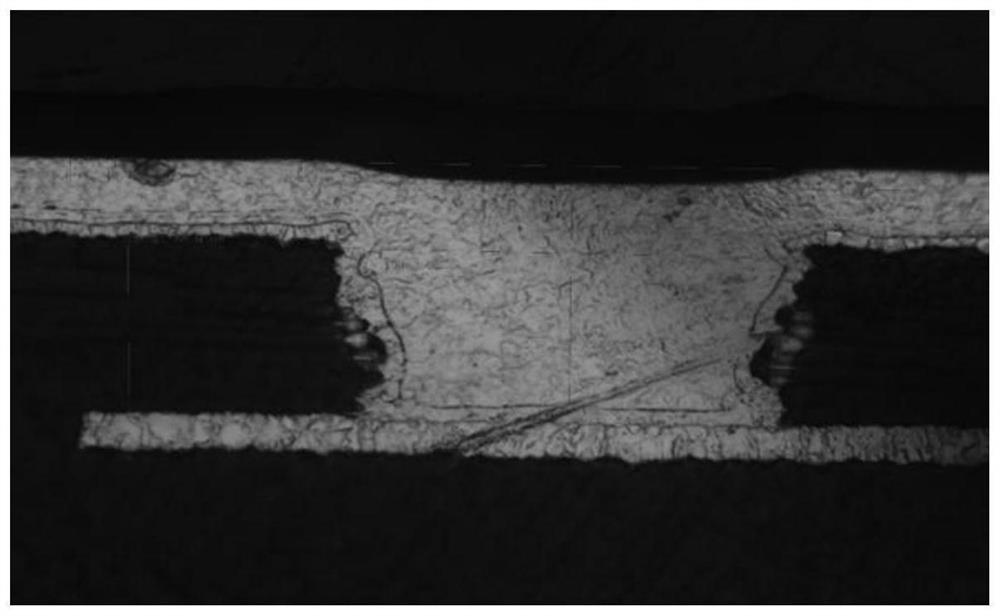

Image

Examples

Embodiment 1

[0040]Add 300g of absolute ethanol and 150g of dimethylamine aqueous solution with a mass fraction of 33% into the reaction vessel, stir and disperse fully, slowly add 145g of pentaerythritol tetraglycidyl ether dropwise, control the ambient temperature at 25-30°C, and stir at a rate of 150rpm Reaction for 16h, after the reaction was completed, the mixture was rotatably evaporated to remove excess dimethylamine, water and ethanol to obtain a yellow oily compound, and 300g of anhydrous ethanol solution containing 84g of allyl chloride was added to the above-mentioned oily compound, and then heated in an oil bath Raise the temperature to 110°C, and stir the reaction at a rate of 150 rpm for 8 hours under reflux. After the reaction, the mixture is rotated and evaporated, and the obtained yellow oil is washed with anhydrous ether several times to obtain a quaternary ammonium salt-type leveling agent;

[0041] Add 200mL deionized water and 0.5mol imidazole compound into the reactio...

Embodiment 2

[0051] Compared with Example 1, this example changes the composition of the quaternary ammonium salt type leveling agent;

[0052] Add 300g of absolute ethanol and 103g of diethylamine aqueous solution with a mass fraction of 33% into the reaction vessel, stir and disperse fully, slowly add 294g of polypropylene glycol diglycidyl ether dropwise, control the ambient temperature at 25-30°C, and at a rate of 150rpm Stir the reaction for 24 hours. After the reaction is completed, the mixture is rotary evaporated to remove excess diethylamine, water and ethanol to obtain a yellow oily compound. Add 300 g of anhydrous ethanol solution containing 14 g of benzyl chloride to the above oily compound, and then heat in an oil bath Raise the temperature to 900°C, and stir the reaction at a rate of 150 rpm for 12 hours under reflux conditions. After the reaction, the mixture is rotated to evaporate, and the obtained yellow oil is washed with anhydrous ether several times to obtain a quaterna...

Embodiment 3

[0062] Compared with Example 1, this example changes the composition of the IMEP type dispersant.

[0063] Add 300g of absolute ethanol and 150g of dimethylamine aqueous solution with a mass fraction of 33% into the reaction vessel, stir and disperse fully, slowly add 145g of pentaerythritol tetraglycidyl ether dropwise, control the ambient temperature at 25-30°C, and stir at a rate of 150rpm Reaction for 16h, after the reaction was completed, the mixture was rotatably evaporated to remove excess dimethylamine, water and ethanol to obtain a yellow oily compound, and 300g of anhydrous ethanol solution containing 84g of allyl chloride was added to the above-mentioned oily compound, and then heated in an oil bath Raise the temperature to 110°C, and stir the reaction at a rate of 150 rpm for 8 hours under reflux. After the reaction, the mixture is rotated and evaporated, and the obtained yellow oil is washed with anhydrous ether several times to obtain a quaternary ammonium salt-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com