Chelation site-containing polyacrylamide, chelation type variable-viscosity slick water and preparation method of chelation site-containing polyacrylamide and chelation type variable-viscosity slick water

A polyacrylamide, chelating type technology, applied in the field of oil and gas field development, can solve the problems of easy shear damage, poor economy, high temperature resistance, etc., to prevent shear damage, good shear resistance, high viscosity increasing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

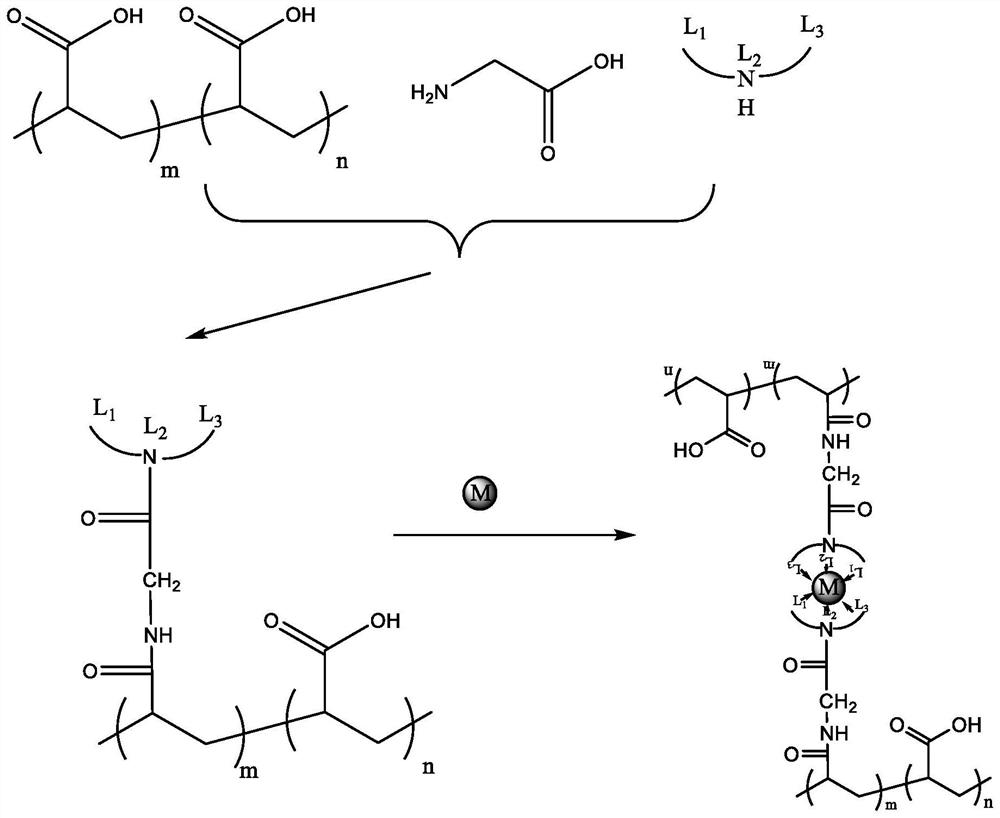

Method used

Image

Examples

Embodiment 1

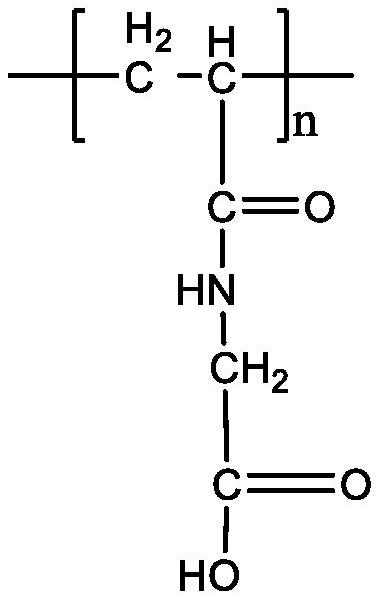

[0043] This example prepares a polyacrylamide solution H1 with carboxyl groups

[0044]

[0045]In 250mL four ports, adding molecular weight is 3,000,000 polyacrylic acid copolymer aqueous solution (Kemax Oil and Gas Field Technology Co., Ltd.), install mechanical stirring, reflux condenser, thermometer and constant pressure dropping funnel, add excess concentration and be 10% glycine aqueous solution ( The molar ratio of polyacrylic acid to amino acid is 1:500) Stir and mix evenly, add 5-methoxy-2-iodophenylboronic acid of 1% of the total molar weight of the monomers, adjust the temperature to 60°C, and keep stirring for 8h, that is The polyacrylamide solution H1 with carboxyl groups was obtained without further purification, and the reaction vessel remained unchanged, which was directly used for the next reaction.

Embodiment 2

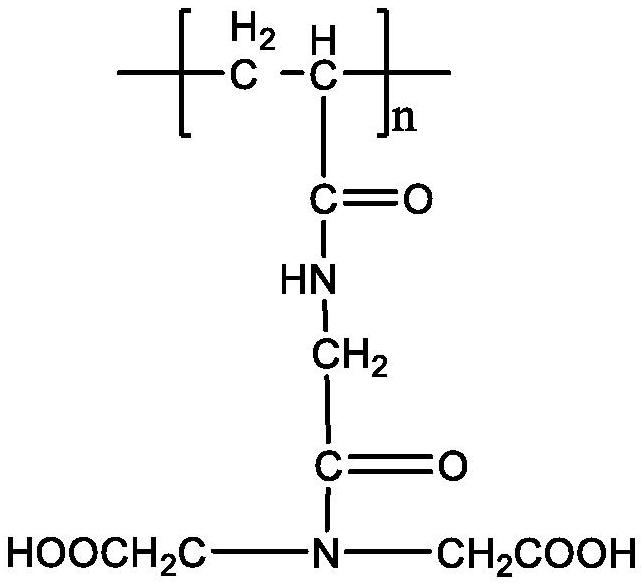

[0047] This example prepares a polyacrylamide CPMA1 containing 0.5% chelating sites

[0048]

[0049] Slowly add iminodiacetic acid into the reaction system in Example 1, so that the molar ratio of carboxyl polyacrylamide and iminodiacetic acid is 1:0.006, the effective content of the polymer is 34%, and the temperature is maintained at 60°C Constant temperature and uniform stirring until the reaction 8h, which contains 0.5% chelate site polyacrylamide CPMA1.

[0050] The reaction process is as follows:

[0051]

Embodiment 3

[0053] This example prepares a chelating type viscous slippery water system CHVSW1

[0054] The sample obtained in Example 2 was dissolved in a 2% mass fraction of ammonium chloride brine under stirring, the mass concentration of the polymer CPMA1 was 0.5%, the stirring time was 2 hours, and the stirring speed was 600 rpm / min. After standing and aging for 2 hours, it was diluted to a polymer concentration of 0.1% by mass concentration, and its initial viscosity was 2.4 mPa·s. Add FeCl 3 The concentration of the aqueous solution is 12mg / L, and the system becomes viscous rapidly, and a chelating type viscous slippery water system CHVSW1 is obtained. Tested by Haake rheometer at 85°C, 170S -1 The viscosity at the shear frequency is 31.2mPa·s, and the test data is shown as 2# in Table 1, which proves that it can be used as an excellent viscous slippery water.

[0055] Table 1: Viscosity Test Data

[0056] serial number temperature shear frequency viscosity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com