Epoxy acrylate modified polyether polyol and preparation method thereof

A technology of epoxy acrylate and polyether polyol, which is applied in the field of polyether polyol modification, can solve the problems of high brittleness and insufficient flexibility, and achieve the effects of good adhesion, low price and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

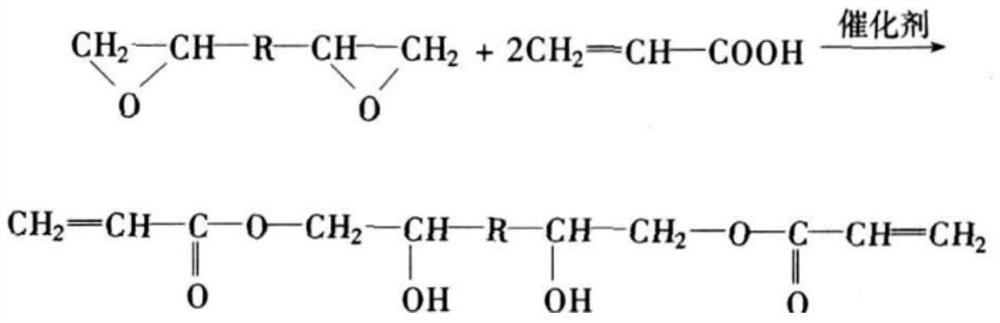

Method used

Image

Examples

Embodiment 1

[0029] Add 100g of epoxy resin E44 into the reaction kettle. After the leak test and replacement of the kettle, the temperature is raised to 85±5°C under nitrogen atmosphere, and then 15.5g of acrylic acid, 1.1g of triethylamine catalyst and hydroquinone are added dropwise within 1 hour. For a mixture of 0.15g of polymerization agent, control the reaction temperature at 100°C, and take samples to measure the acid value at the same time. After the dropwise addition, raise the temperature to 115±5°C and react for 1.5h, so that the acid value drops to less than 2mgKOH / g to stop the reaction.

[0030] After the internal pressure is completed, take 325g of sucrose and vacuum pump it into the reaction kettle. At the same time, add 80g of diethylene glycol, 2g of diethanolamine, 226g of palm oil, and 12g of triethylamine catalyst. Stir and cool down to 110°C. Propylene oxide, the mass is 581g, the temperature is kept at 112±2°C during the dropwise addition, and the pressure in the ket...

Embodiment 2

[0032] Add 100g of epoxy resin F51 (feed after heating) into the reaction kettle. After the leak test and replacement of the kettle, the temperature is raised to 85±5℃ under a nitrogen atmosphere, and then 33.4g of acrylic acid and N,N-dimethyl are added dropwise within 1 hour. Benzylamine catalyst 1.3g and p-methoxyphenol 0.2g inhibitor mixture, control the reaction temperature at 100°C, take a sample to measure the acid value at the same time, after the dropwise addition, raise the temperature to 115±5°C and react for 2h to reduce the acid value to less than 2mgKOH / g stops the reaction.

[0033] After the internal pressure is completed, 325g of sucrose is vacuum pumped into the reactor, and 165g of diethylene glycol, 3g of diethanolamine, and 12g of dimethylamine catalyst are sucked in at the same time, and the temperature is lowered to 110°C with stirring. After reaching the temperature, propylene oxide is added dropwise. In 859g, keep the temperature at 112±2°C during the...

Embodiment 3

[0035] Add 100g of epoxy resin E55 (feeding after heating) into the reaction kettle. After leak test and replacement of the kettle, the temperature is raised to 85±5°C under nitrogen atmosphere, and then 19.9g of methacrylic acid, N,N-di Mix 1.2g of methylbenzylamine catalyst and 0.17g of p-methoxyphenol as a polymerization inhibitor, control the reaction temperature at 100°C, and take samples to measure the acid value at the same time. Less than 2mgKOH / g to stop the reaction.

[0036] After the internal pressure is completed, 325g of sucrose is vacuum pumped into the reaction kettle, and 165g of diethylene glycol, 2.6g of diethanolamine, and 12g of dimethylamine catalyst are sucked in at the same time, and the temperature is lowered to 110°C with stirring. After reaching the temperature, propylene oxide is added dropwise. The mass is 850g, the temperature is kept at 112±2°C during the dropping process, and the pressure in the kettle is controlled within 0.2MPa. After the dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com