Platycodon grandiflorum polysaccharide extraction method based on micro-thermal blasting wall surface

A technology of platycodon grandiflorum polysaccharide and extraction method, which is applied in the field of platycodon grandiflorum polysaccharide extraction based on microthermal blasting wall, can solve the problems of reducing production cost and difficulty in extracting platycodon grandiflorum polysaccharide, and achieves the effects of reducing production cost, low equipment requirements and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

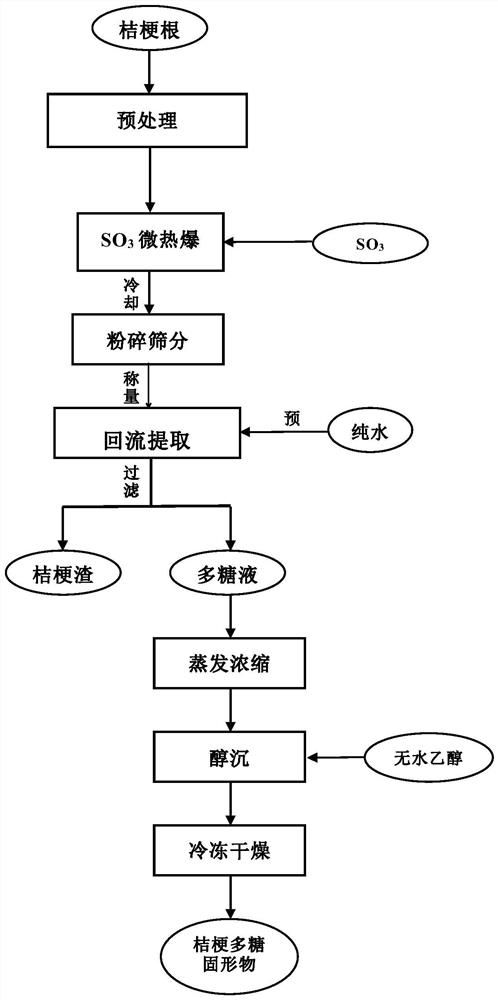

[0031] A method for extracting platycodon polysaccharides based on micro-heat blasting walls, the method comprising:

[0032] (1) Select the root part of fresh platycodon grandiflora, remove the skin whiskers, clean it, blow dry it, weigh it, and measure the water content, dry it at 60°C until the platycodon grandiflorum with a water content of 15% is cut longitudinally, and cut into 1~ 2cm small section;

[0033] (2) Put the bellflower segments with a water content of 15% in SO 3 Microthermal explosion reaction in gas, platycodon mass and SO 3 The volume ratio is 1g: 25mL for reaction, the treatment temperature for micro-heat explosion is 50°C, and the treatment time is 30min;

[0034] (3) will SO 3 The platycodon root after micro-heat explosion treatment is pulverized, and crosses an 80-mesh sieve;

[0035] (4) After degreasing the pulverized Platycodon grandiflorum root with petroleum ether, reflux with hot water at 60°C for 90 minutes at a material-to-liquid ratio of 1...

experiment example 1

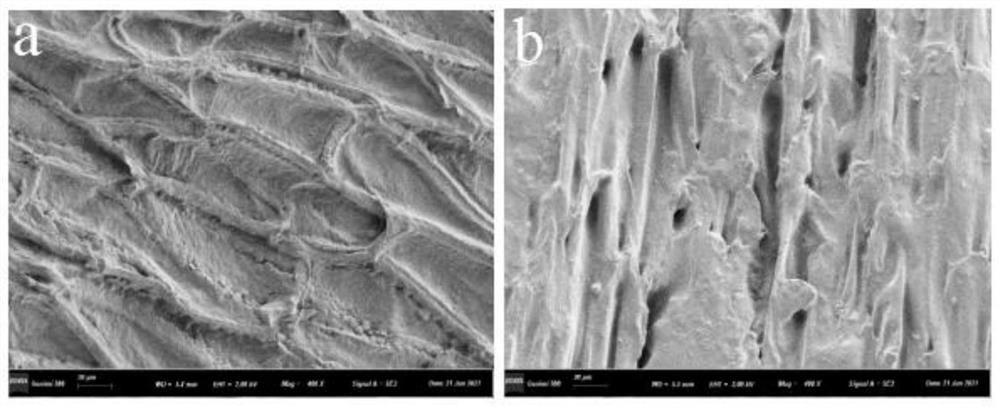

[0038] Experimental example 1 on SO 3 SEM characterization analysis of platycodon grandiflorum treated by micro-thermal explosion technology

[0039] Using a JSM-6490LV tungsten filament scanning electron microscope (SEM) to observe untreated and treated SO 3 Surface microstructure of Platycodon grandiflorum pretreated by micro-thermal explosion technology.

[0040] Firstly, the samples before and after pretreatment are made into a block with a size of 2mm×2mm, and then the sample is adhered to the copper sample stage with conductive glue, and the sample stage is placed in a gold-spraying device for gold spraying to make the Chinese herbal medicine have Conductivity, and then can be observed, where the equipment acceleration voltage is 0.5 ~ 30kV.

[0041] From figure 2 As shown in the figure, a is the bellflower that has not been slightly heated, and b is the bellflower that has been slightly heated. It can be seen that the pretreatment process has destroyed the cell wall...

experiment example 2

[0042] Experimental Example 2 Anthrone-sulfuric acid method for measuring the absorbance value of the extract

[0043] (1) Preparation of anthrone-sulfuric acid reagent

[0044]Accurately weigh 100 mg of anthrone, and slowly add 100 mL of concentrated sulfuric acid. It should be noted that the anthrone-sulfuric acid reagent should not be stored for a long time, and should be used immediately after mixing. If the color becomes darker, it cannot be used.

[0045] (2) Preparation of glucose standard stock solution

[0046] Accurately weigh 100mg of anhydrous glucose (dried overnight in a constant temperature blast oven at 105°C in advance), put it in a beaker and add an appropriate amount of pure water to fully dissolve it, and then set the volume to a 100mL volumetric flask to obtain glucose with a concentration of 1mg / mL Standard stock solution.

[0047] (3) Drawing of glucose standard curve

[0048] Precisely pipette 1mg / mL glucose standard solution 0mL, 0.05mL, 0.1mL, 0.2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com