Polymer sterilizing flocculant for oil field as well as preparation method and application of polymer sterilizing flocculant

A flocculant and polymer technology, applied in the field of oil field polymer bactericidal flocculants and their preparation, can solve the problems of different compounding concentrations, increasing difficulty, complicated operation, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

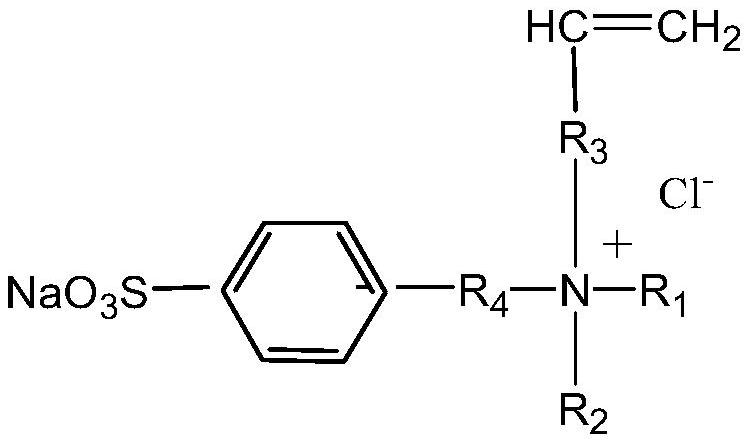

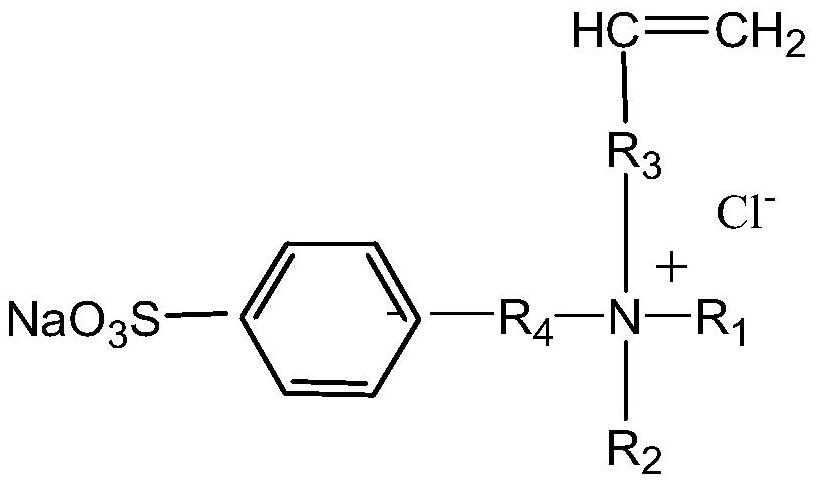

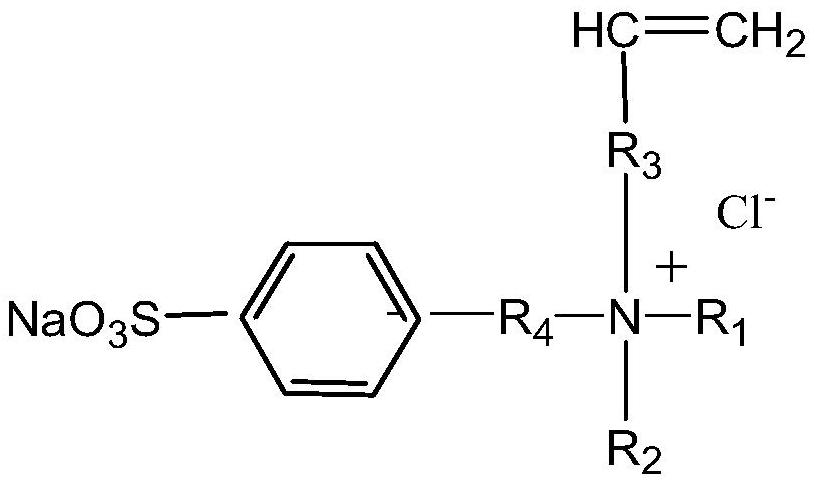

[0025] According to the first aspect of the present invention, the present invention provides a kind of preparation method of oil field macromolecule bactericide flocculant, described preparation method comprises the following steps:

[0026] (1) In the presence of co-solvent A and lye, aliphatic secondary amines and chlorinated alkenes undergo the first step of substitution reaction to generate tertiary amines.

[0027] (2) In the presence of an organic solvent, the second-step substitution reaction of the tertiary amine generated in step (1) and sodium chloroalkylbenzenesulfonate occurs to generate a quaternary ammonium salt.

[0028] (3) In the presence of cosolvent B, buffer salt and initiator, the quaternary ammonium salt generated in step (2) is polymerized to obtain the crude product of the bactericidal flocculant.

[0029] (4) Adding a reducing agent dropwise to the bactericidal flocculant mixture obtained by the polymerization reaction in step (3), removing excess ini...

Embodiment 8

[0143] Example 8 Field application of bactericidal flocculant C

[0144] Union Station G 12 The incoming water is produced water from an oil production plant in Shengli Oilfield, and the treatment scale is 4000m 3 / d, the content of sulfate-reducing bacteria in the produced water is 60 / ml, and the content of suspended solids is 80 mg / L. Utilize the bactericidal flocculant C of the present invention to combine station G 12 The produced water was sterilized and flocculated. The dosage of bactericidal flocculant C was 40kg / d. After the treatment, the content of sulfate-reducing bacteria was reduced to 0 / ml, and the bactericidal rate was 100%. The bactericidal effect was good and met the process requirements. After treatment, the content of suspended solids is reduced to 5mg / L, the removal rate of suspended solids is 94%, and the flocculation effect is good, meeting the technological requirements.

Embodiment 9

[0145] Field application of embodiment 9 bactericidal flocculant D

[0146] Union Station C 4 The incoming water is produced water from an oil production plant in Shengli Oilfield, and the treatment scale is 3000m 3 / d, the content of sulfate-reducing bacteria in the produced water is 25 / ml, and the content of suspended matter is 60 mg / L. Utilize the bactericidal flocculant D of the present invention to combine station C 4 The produced water is treated with bactericidal flocculation, and the dosage of bactericidal flocculant D is 30kg / d. After treatment, the content of sulfate-reducing bacteria is reduced to 0 / ml, and the bactericidal rate is 100%. The bactericidal effect is good and meets the process requirements. After treatment, the content of suspended solids was reduced to 8mg / L, the removal rate of suspended solids was 87%, and the flocculation effect was good, meeting the technological requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com