Method for preparing dicyclopentadiene dioxide DCPDDO and 2-phenyl-2-propanol

A technology of dicyclopentadiene and propanol dioxide is applied in chemical instruments and methods, hydrogenation preparation, oxygen-containing functional group reduction preparation, etc., to achieve the effects of improved reaction process safety, high product yield, and simple process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Preparation of titanium silicon molecular sieve catalyst

[0049] At room temperature and under stirring conditions, add 10 grams of hexadecylamine to 112 ml of water and 110 milliliters of ethanol successively in the reactor, and stir; Add it to the above solution, stir for 30 minutes, crystallize for 12 hours, add 18.7 grams of carbon nanofibers, continue stirring for 10 to 72 hours, heat up the reactor, crystallize the reaction material at 200°C for 1 day, filter to obtain a solid, and extract the catalyst with ethanol template agent, and then washed with pure water until the eluent was neutral. After drying the washed solid at 110° C. for 12 hours, Ti-HMS supported by carbon nanofibers was obtained.

[0050] Add 3 times the volume of pure water, 1.2 grams of Mg(OH) 2 , room temperature, stirred for 48 hours, separated the solid, washed with pure water until the washing liquid was neutral, dried at 80°C for 20 hours, and then calcined at 400°C for 20 ...

Embodiment 2~9

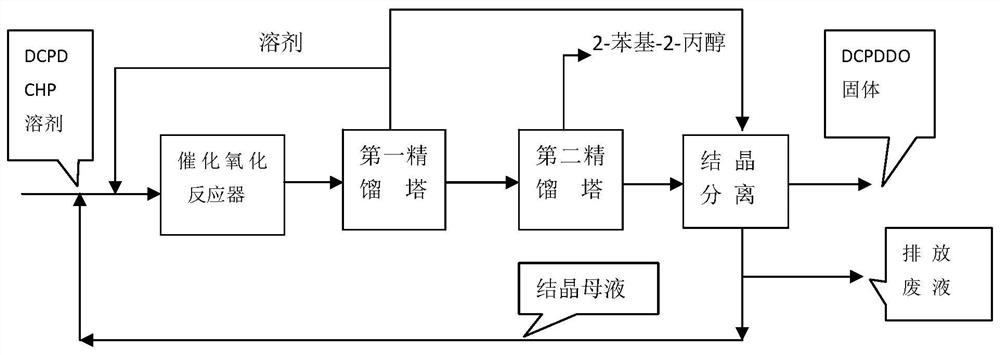

[0052] Embodiment 2~9: Tank reactor, the mixed solution of main product DCPDDO and 2-phenyl-2-propanol obtained by catalytic oxidation:

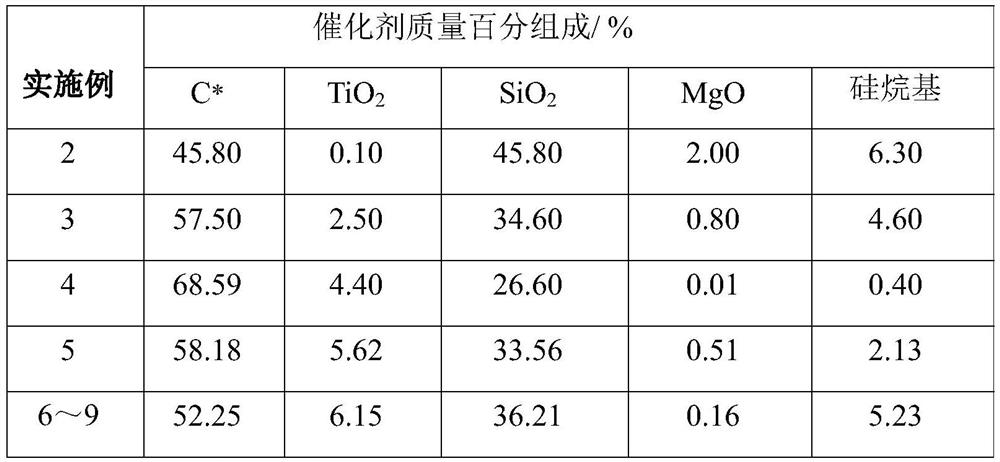

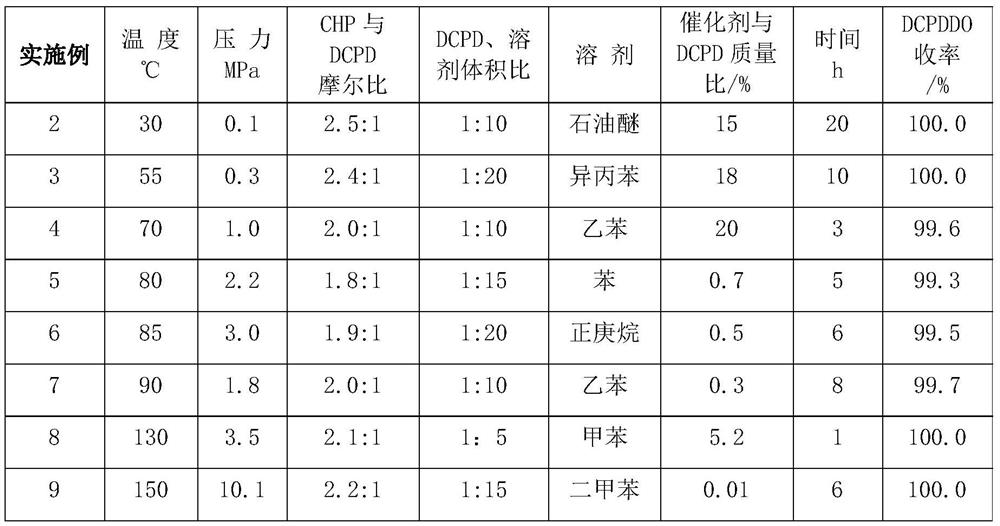

[0053] Get titanium-silicon molecular sieve catalyst, cumene hydroperoxide CHP, and solvent are fed into 500 milliliters of reaction kettles according to technological requirements, rectify and separate solvent, 2-phenyl-2-propanol after the reaction is completed, and then separate DCPDDO, The crystallization mother liquor is mixed with fresh reaction raw materials and put into the reactor to continue the reaction of the next batch. The effects of temperature, pressure, material ratio, and reaction time on the yield of the reaction product DCPDDO were investigated. The catalyst compositions used in Examples 2-9 are shown in Table 1, and the experimental results are shown in Table 2.

[0054] Table 1 Catalyst mass percent composition

[0055]

[0056] *Note: C—indicates carbon nanofiber.

[0057] Table 2 Batch Reaction Synthesis of DCPDD...

Embodiment 10~17

[0059] Examples 10-17: Catalytic oxidation synthesis of DCPDDO and 2-phenyl-2-propanol mixed solution by fixed-bed continuous reaction process

[0060] Take 40 grams of titanium-silicon molecular sieve catalyst, fill it into a 100 ml isothermal fixed-bed reactor, use cumene hydroperoxide CHP as the oxidant, and inject the reaction feed liquid into the reactor through a metering pump. The reaction product is separated from the solvent and 2-phenyl-2-propanol by rectification, DCPDDO is separated by crystallization, the crystallization mother liquor is mixed with fresh reaction raw materials and re-entered the reactor, and the effects of temperature, pressure, material ratio and space velocity on the reaction product are investigated. The influence of DCPDDO yield, the catalyst compositions used in Examples 10-17 are shown in Table 3, and the experimental results are shown in Table 4.

[0061] Table 3 Catalyst mass percent composition

[0062]

[0063] *Note: C—indicates carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com