Metallographic etchant suitable for nickel-molybdenum alloy and etching method

A metallographic erosion and nickel-molybdenum alloy technology, applied in the field of metallographic etchant, can solve the problems of excessive corrosion, difficult observation of grain boundaries, and many steps, and achieve good repeatability, clear grain boundaries and carbides, and chemical composition safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

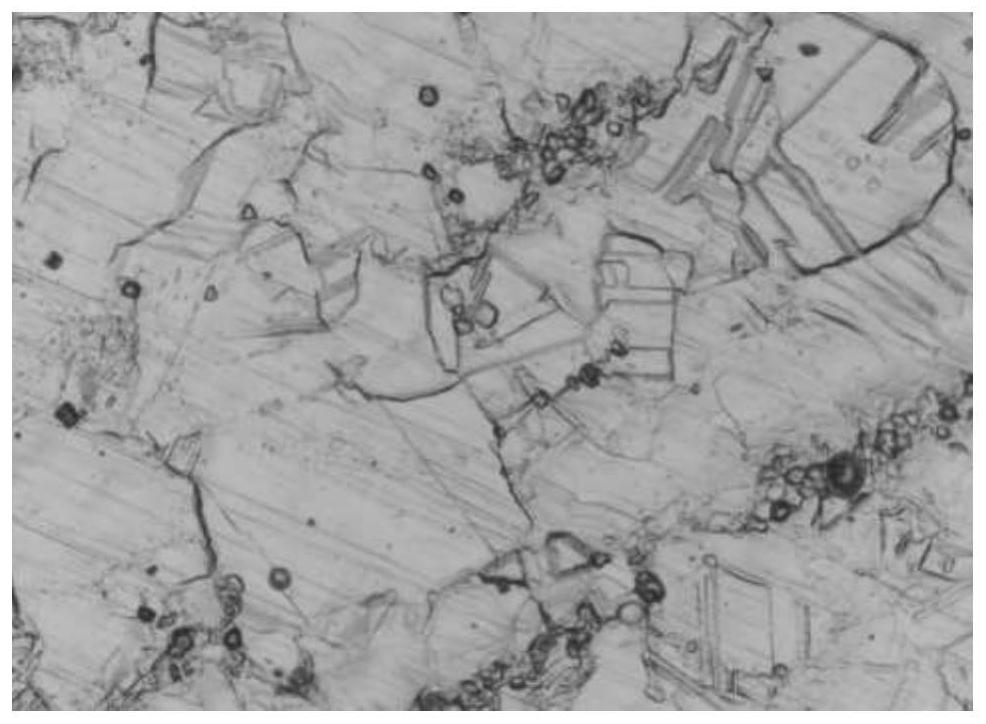

Embodiment 1

[0049](1) Prepare metallographic etchant: add 36% hydrochloric acid 20g, phosphoric acid 15g respectively in 20g water, leave standstill 20min after the glass rod stirs; Add methanol 20g, p-toluenesulfonic acid 10g and benzidine glycolic acid 15g again, stir evenly, Obtain a metallographic etchant;

[0050] (2) The pretreated HB3 alloy is used as the anode and the graphite rod is used as the cathode, which are respectively installed at both ends of the electrolytic cell; wherein, the shape of the anode and the cathode are both rod-shaped, and the effective area is 1cm 2 , the linear distance between the anode and the cathode is 5cm;

[0051] (3) Pour the metallographic etchant prepared in step (1) into the electrolytic tank as electrolyte, turn on the power supply and carry out electrolytic corrosion; control the current density to be 0.5mA / cm 2 , the electrolysis potential is 2V, and the electrolysis time is 1min;

[0052] (4) After the electrolysis is completed, the HB3 al...

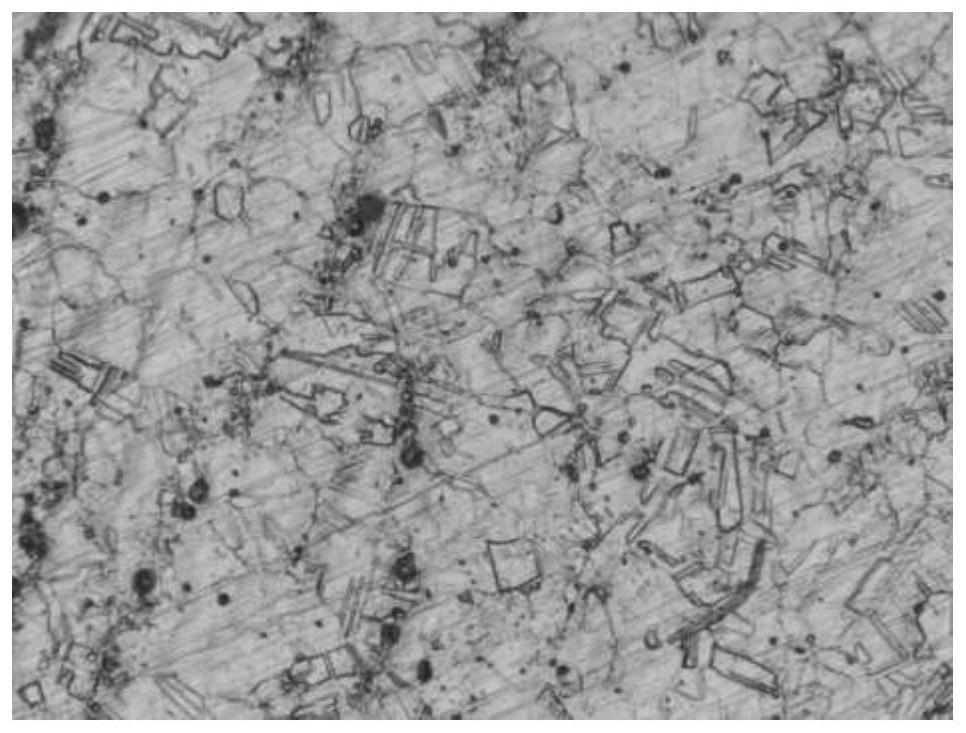

Embodiment 2

[0054] (1) Prepare metallographic etchant: add 36% hydrochloric acid 10g, phosphoric acid 20g respectively in 20g water, leave standstill 20min after the glass rod stirs; Add methanol 15g, p-toluenesulfonic acid 15g and benzidine glycolic acid 20g again, stir evenly, Obtain a metallographic etchant;

[0055] (2) The pretreated HB3 alloy is used as the anode and the graphite rod is used as the cathode, which are respectively installed at both ends of the electrolytic cell; wherein, the shape of the anode and the cathode are both rod-shaped, and the effective area is 1cm 2 , the linear distance between the anode and the cathode is 5cm;

[0056] (3) Pour the metallographic etchant prepared in step (1) into the electrolytic tank as electrolyte, turn on the power supply and carry out electrolytic corrosion; control the current density to be 0.5mA / cm 2 , the electrolysis potential is 2V, and the electrolysis time is 2min;

[0057] (4) After the electrolysis is completed, the HB3 a...

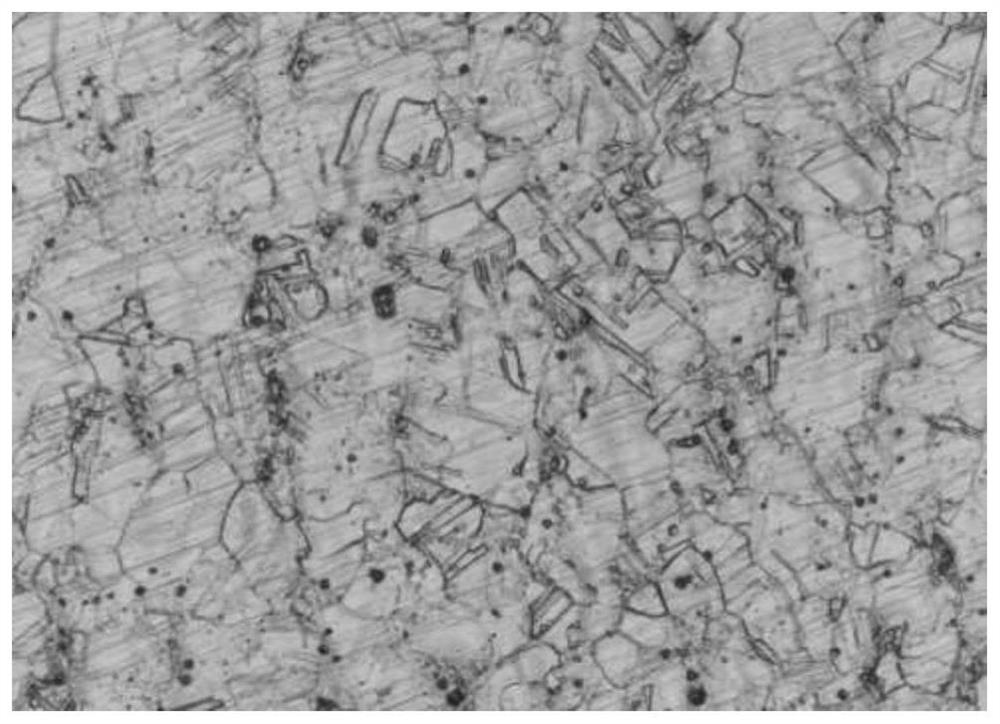

Embodiment 3

[0059] (1) Prepare metallographic etchant: add 36% hydrochloric acid 15g, phosphoric acid 10g respectively in 20g water, leave standstill 20min after the glass rod stirs; Add methanol 25g, p-toluenesulfonic acid 15g and benzidine glycolic acid 15g again, stir evenly, Obtain a metallographic etchant;

[0060] (2) The pretreated HB3 alloy is used as the anode and the graphite rod is used as the cathode, which are respectively installed at both ends of the electrolytic cell; wherein, the shape of the anode and the cathode are both rod-shaped, and the effective area is 1cm 2 , the linear distance between the anode and the cathode is 5cm;

[0061] (3) Pour the metallographic etchant prepared in step (1) into the electrolytic cell as electrolyte, turn on the power supply and carry out electrolytic corrosion; control the current density to be 0.4mA / cm 2 , the electrolysis potential is 3V, and the electrolysis time is 2min;

[0062] (4) After the electrolysis is completed, the HB3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com